- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

3000 r.p.m

-

Max. Weight of Workpiece(kg):

-

550

-

Spindle Bore(mm):

-

57

-

Width of bed (mm):

-

316 mm

-

Spindle Motor Power(kW):

-

5.5

-

Max. Turned Length (mm):

-

600

-

Travel (X Axis)(mm):

-

200 mm

-

Travel (Z Axis)(mm):

-

610 mm

-

Positioning Accuracy (mm):

-

0.026

-

Repeatability (X/Y/Z) (mm):

-

0.007

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

2150*1260*1600

-

Brand Name:

-

BLIN

-

Model Number:

-

BL-TK36S/EK40

-

Voltage:

-

380

-

Weight (KG):

-

1700

-

Max. swing dia. over slide:

-

180mm

-

Max. turning dia.:

-

320mm

-

Center distance:

-

750mm

-

Chuck size:

-

8 inch

-

X/Z axes rapid speed:

-

6/8 m/min

-

Tool shank size:

-

20*20,32mm

-

X/Z axes positioning accuracy:

-

0.026

-

Turning workpiece roundness:

-

0.004

-

Total power:

-

12KVA

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

1000

-

Year:

-

2010

-

Max. Spindle Speed (r.p.m):

-

3000 r.p.m

-

Max. Weight of Workpiece(kg):

-

550

-

Spindle Bore(mm):

-

57

-

Width of bed (mm):

-

316 mm

-

Spindle Motor Power(kW):

-

5.5

-

Max. Turned Length (mm):

-

600

-

Travel (X Axis)(mm):

-

200 mm

-

Travel (Z Axis)(mm):

-

610 mm

-

Positioning Accuracy (mm):

-

0.026

-

Repeatability (X/Y/Z) (mm):

-

0.007

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

2150*1260*1600

-

Brand Name:

-

BLIN

-

Model Number:

-

BL-TK36S/EK40

-

Voltage:

-

380

-

Weight (KG):

-

1700

-

Max. swing dia. over slide:

-

180mm

-

Max. turning dia.:

-

320mm

-

Center distance:

-

750mm

-

Chuck size:

-

8 inch

-

X/Z axes rapid speed:

-

6/8 m/min

-

Tool shank size:

-

20*20,32mm

-

X/Z axes positioning accuracy:

-

0.026

-

Turning workpiece roundness:

-

0.004

-

Total power:

-

12KVA

|

■Adopt China best high strength compound resin sand cast iron

|

|

|

|

|

||||

|

■Aging treatment,has good vibration absorption and rigidity

|

|

|

|

|

||||

|

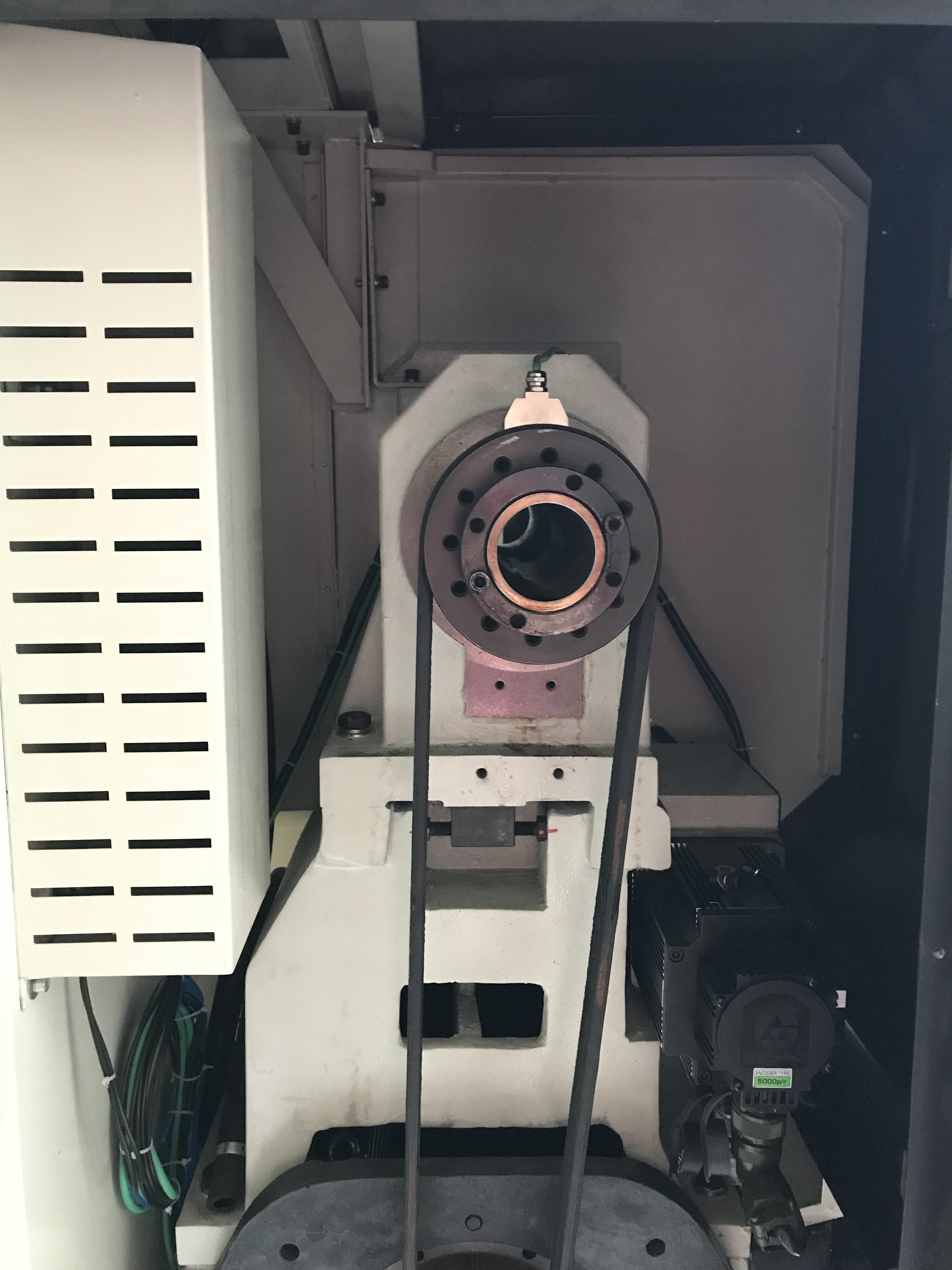

■Adopt independent spindle,3000rpm high speed, especially suitable for nonferrous metal processing

|

|

|

|

|

||||

|

■Spindle unit adopt precise angle contact ball bearing and double column cylindrical roller bearings

|

|

|

|

|

||||

|

■Guideway hardened by ultrasonic frequency and precise ground, good precision keeping

|

|

|

|

|

||||

|

■Guideway stick PTFE,remove creeping,obviously increase precision, wearability and anti-impact force

|

|

|

|

|

||||

|

■Adopt independent coolant tank design

|

|

|

|

|

||||

|

Item

|

Specification

|

Unit

|

BL-TK36S

|

BL-EK40

|

|

|

Capacity

|

Guideway width

|

mm

|

316

|

|

|

|

|

Max. swing dia. over bed

|

mm

|

Φ360

|

Φ400

|

|

|

|

Max. swing dia. over slide

|

mm

|

Φ180

|

Φ200

|

|

|

|

Max. turning dia.

|

mm

|

Φ320

|

Φ400

|

|

|

|

Center distance

|

mm

|

750

|

750/1000

|

|

|

|

Max turning length

|

mm

|

600

|

580/830

|

|

|

|

Max. workpiece weight

|

kg

|

550

|

|

|

|

Spindle

|

Spindle bore

|

mm

|

Φ57

|

|

|

|

|

Spindle head type

|

/

|

ISO702/Ⅰ A2-6(manual chuck, 8’’ hydraulic chuck);

ISO702/Ⅰ A2-5(6’’ hydraulic chuck) |

|

|

|

|

Spindle speed

|

rpm

|

140~3000(stepless)

|

|

|

|

|

Chuck size

|

/

|

8’’

|

|

|

|

|

Spindle motor

|

kw

|

5.5

|

|

|

|

X/Z axes

|

X axes travel

|

mm

|

200

|

230

|

|

|

|

Z axes travel

|

mm

|

610

|

590/840

|

|

|

|

X/Z axes ball screw O.D/pitch.

|

mm

|

Φ25/5,Φ40/6

|

|

|

|

|

X/Z axes rapid rate

|

m/min

|

6/8

|

|

|

|

|

X/Z axes positioning accuracy

|

mm

|

0.026/0.032

|

0.026/0.032

|

|

|

|

X/Z axes repositioning accuracy

|

mm

|

0.007/0.009

|

0.007/0.009

|

|

|

Tool post

|

Tool post

|

/

|

Vertical 4/Horizontal 6 station/gang tool

|

|

|

|

|

Toolshank size

|

mm

|

20×20,Φ32

|

|

|

|

Tailstock

|

Tailstock quill travel

|

mm

|

120

|

120

|

|

|

|

Tailstock quill dia.

|

|

Φ55

|

Φ65

|

|

|

|

Tailstock quill taper

|

/

|

MT4#

|

|

|

|

Others

|

N.W.

|

kg

|

1700

|

1700/2100

|

|

|

|

Overall size(L×W×H)

|

mm

|

2150×1260×1600

|

2150×1260×1600

|

|

Standard configuration:

●FANUC 0i TF CNC Controller

●Manual chuck

●4 station tool post

●Manual tailstock

●Manual chuck

●4 station tool post

●Manual tailstock

Optional configuration:

●SIEMENS 808D/GSK980TDi

●Hydraulic chuck

●6 station tool turret

●Hydraulic tailstock

●Hydraulic chuck

●6 station tool turret

●Hydraulic tailstock

Product Category

About Us

Packing & Shipping

Q1.Are you manufacturer or trading company?

A. We are professional machine tool manufacturer, we have total 3 manufacturers in CHINA and set export sales center & showroom in NINGBO city.

Q2. How about your price?

A. We have different series, covered high, middle, economical class with super high performance-price ratio. You may check with us for most suitable solutions.

Q3. Can you provide training for operation CNC machines?

A.Yes, free training in our factory is available.

Q4. What's your warranty terms?

A. We will supply a replacement for parts that prove to be defective for a period of one year (3 years for SIEMENS parts) , starting from one month after shipping date. Please contact us for more details.

Q5.Do you have CE certificate?

A. Yes,we have.

Q6. What’s the delivery time & package?

A.Depends on machine model and configuration. Normally not more than 45days. Please contact us to confirm. All our CNC machines are packed with sea worthy package.

Q7.What is MOQ?

A.1 Unit.

Homepage

Hot Searches