- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

UKO-Second Punch

-

Product Type:

-

Screw Punch, Recess Punch, Header Punch, Second Punch

-

Material Grade:

-

SKH-9/ M42

-

Slots of Standards:

-

JIS, ANSI, DIN, ISO, GB, BS, KS

-

Application:

-

marking, stamping, and extrusion of heading slots of screw fasteners

-

Surface Treatment:

-

Uncoated, TiN Coating, TiAlN Coating

-

Screw Header Type:

-

Bugle, Pan, Countersunk, Oval, Hex or Custom

-

Drive type:

-

Philips, Pozi, Slot, Square, Trox, Combine or Custom

-

Diameters:

-

12mm, 14mm, 18mm, 23mm, 25mm, 30mm

-

Length:

-

15mm, 20mm, 25mm

-

Screw Type:

-

Machine Screw, Self-Tapping Screw, Drywall Screw, Wood Screw

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

UKO

-

Model Number:

-

UKO-Second Punch

-

Product Type:

-

Screw Punch, Recess Punch, Header Punch, Second Punch

-

Material Grade:

-

SKH-9/ M42

-

Slots of Standards:

-

JIS, ANSI, DIN, ISO, GB, BS, KS

-

Application:

-

marking, stamping, and extrusion of heading slots of screw fasteners

-

Surface Treatment:

-

Uncoated, TiN Coating, TiAlN Coating

-

Screw Header Type:

-

Bugle, Pan, Countersunk, Oval, Hex or Custom

-

Drive type:

-

Philips, Pozi, Slot, Square, Trox, Combine or Custom

-

Diameters:

-

12mm, 14mm, 18mm, 23mm, 25mm, 30mm

-

Length:

-

15mm, 20mm, 25mm

-

Screw Type:

-

Machine Screw, Self-Tapping Screw, Drywall Screw, Wood Screw

Customized Screw Punch Header Punch for Cold Heading Machine Model 104 105 106

Product Description

The second punch is an essential component of cold heading machines, designed to shape and form metal blanks into desired shapes and sizes. It is typically used in the production of fasteners, screws, bolts, and other metal components used in various industries.

Advantages

Benefits

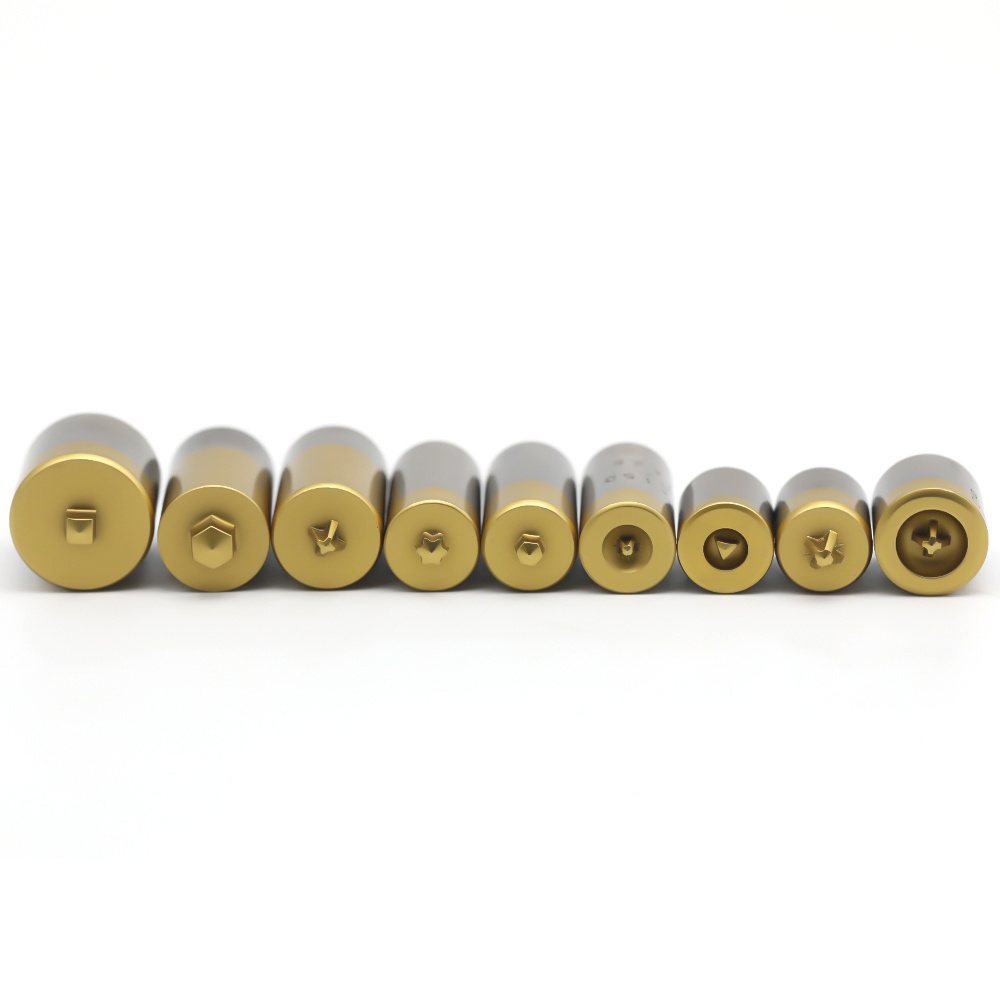

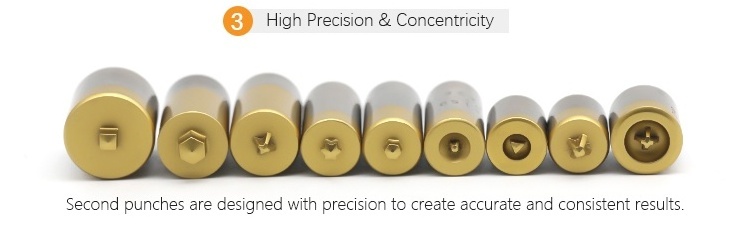

Improved product quality: Second punches are designed with precision to create accurate and consistent results, which is crucial for maintaining high-quality standards for the finished product.

Cost savings: Second punches are made from high-quality materials and are designed for durability, reducing replacement costs and downtime. The use of second punches in the cold heading process also allows for a high production rate of precision components with minimal waste, leading to cost savings.

Increased efficiency: The use of second punches in the cold heading process allows for a high production rate of precision components with minimal waste, which can lead to improved efficiency in the manufacturing process.

Technical Parameters

Material Grade for Second Punch:

|

Material-JIS

|

Material-AISI

|

Hardness

|

Applications

|

|

SKH-9

|

M2

|

61-64 HRC

|

Used for cold forging die, punches, flat dies, punch pins, etc.

|

|

SKH-55

|

M35

|

63-66 HRC

|

Used for advanced screw dies etc.

|

|

ASP-30

|

M42

|

66-68 HRC

|

Used for making high-heavy-load dies, pins of powdered high-speed steel/ stainless steel screws, and punches of hollow rivets.

|

Characteristics and Properties of Punch Coatings:

|

Type

|

TiN

|

TiCN

|

TiAlN

|

CrN

|

WC/C

|

ALCRONA

|

|

Hardness

|

Hv2000

|

Hv3000

|

Hv3000~Hv5000

|

Hv1800

|

Hv1400

|

Hv3200

|

|

Surface roughness

|

0.4

|

0.3~0.4

|

0.4

|

0.5

|

0.1

|

0.35

|

|

Layer thickness

|

2-4 um

|

2-4 um

|

2-5 um

|

3-6 um

|

1-4 um

|

2-4 um

|

|

Coating color

|

gold

|

gray

|

dark purple

|

silver

|

black

|

dark purple

|

|

Max working temperature

|

550℃

|

400℃

|

850-1000℃

|

700℃

|

300℃

|

1100℃

|

Specification

|

Screw Header Type

|

OVAL

|

|

|

|

|||

|

Specifications

|

d2

|

d1/ (Tol.)

|

|

m (Tol.)

|

|||

|

M2.0

|

12

|

4

|

(-0.4)

|

2.4

|

|||

|

M2.2

|

12

|

4.4

|

(-0.4)

|

2.7

|

|||

|

M2.3

|

12

|

4.6

|

(-0.4)

|

2.7

|

|||

|

M2.5

|

12

|

5

|

(-0.4)

|

2.9

|

|||

|

M2.6

|

12

|

5.2

|

(-0.4)

|

2.9

|

|||

|

M3.0

|

12

|

6

|

(-0.5)

|

3.8

|

|||

|

M3.5

|

12, 14

|

7

|

(-0.5)

|

4.3

|

|||

|

M4.0

|

14

|

8

|

(-0.5)

|

4.7

|

|||

|

M4.5

|

14, 18

|

9

|

(-0.6)

|

5.1

|

|||

|

M5.0

|

18

|

10

|

(-0.6)

|

5.3

|

|||

|

M6.0

|

18

|

12

|

(-0.7)

|

6.8

|

|||

|

M8.0

|

23

|

16

|

(-0.8)

|

8.5

|

|||

|

Screw Header Type

|

ROUND

|

|

|

|

|||

|

Specifications

|

d2

|

d1/ (Tol.)

|

|

m (Tol.)

|

|||

|

M2.0

|

12

|

3.5

|

(-0.4)

|

2.1

|

|||

|

M2.2

|

12

|

4

|

(-0.4)

|

2.3

|

|||

|

M2.3

|

12

|

4

|

(-0.4)

|

2.5

|

|||

|

M2.5

|

12

|

4.5

|

(-0.4)

|

2.5

|

|||

|

M2.6

|

12

|

4.5

|

(-0.4)

|

2.5

|

|||

|

M3.0

|

12

|

5.5

|

(-0.5)

|

3.5

|

|||

|

M3.5

|

12, 14

|

6

|

(-0.5)

|

3.8

|

|||

|

M4.0

|

14

|

7

|

(-0.5)

|

4.1

|

|||

|

M4.5

|

14, 18

|

8

|

(-0.6)

|

4.5

|

|||

|

M5.0

|

18

|

9

|

(-0.6)

|

4.8

|

|||

|

M6.0

|

18

|

10.5

|

(-0.7)

|

6.1

|

|||

|

M8.0

|

23

|

14

|

(-0.8)

|

7.6

|

|||

|

Screw Header Type

|

FLAT

|

|

|

|

|||

|

Specifications

|

d2

|

d1/ (Tol.)

|

|

m (Tol.)

|

|||

|

M2.0

|

12

|

4

|

(-0.4)

|

2.2

|

|||

|

M2.2

|

12

|

4.4

|

(-0.4)

|

2.4

|

|||

|

M2.3

|

12

|

4.6

|

(-0.4)

|

2.4

|

|||

|

M2.5

|

12

|

5

|

(-0.4)

|

2.6

|

|||

|

M2.6

|

17

|

5.2

|

(-0.4)

|

2.6

|

|||

|

M3.0

|

12

|

6

|

(-0.5)

|

3.6

|

|||

|

M3.5

|

12

|

7

|

(-0.5)

|

4.1

|

|||

|

M4.0

|

12, 14

|

8

|

(-0.5)

|

4.5

|

|||

|

M4.5

|

12, 14

|

9

|

(-0.6)

|

4.9

|

|||

|

M5.0

|

12, 14

|

10

|

(-0.6)

|

5.1

|

|||

|

M6.0

|

18

|

12

|

(-0.7)

|

6.6

|

|||

|

M8.0

|

18

|

16

|

(-0.8)

|

8.3

|

|||

|

Screw Header Type

|

BIND

|

|

|

|

|||

|

Specifications

|

d2

|

d1/ (Tol.)

|

|

m (Tol.)

|

|||

|

M2.0

|

12

|

4.3

|

(-0.4)

|

2.2

|

|||

|

M2.2

|

12

|

4.7

|

(-0.4)

|

2.3

|

|||

|

M2.3

|

12

|

49

|

(-0.4)

|

2.4

|

|||

|

M2.5

|

12

|

5.3

|

(-0.4)

|

2.5

|

|||

|

M2.6

|

17

|

5.5

|

(-0.4)

|

2.6

|

|||

|

M3.0

|

12

|

6.3

|

(-0.5)

|

3.7

|

|||

|

M3.5

|

12, 14

|

7.3

|

(-0.5)

|

4

|

|||

|

M4.0

|

14

|

8.3

|

(-0.5)

|

4.3

|

|||

|

M4.5

|

14

|

93

|

(-0.6)

|

4.7

|

|||

|

M5.0

|

14, 18

|

10.3

|

(-0.6)

|

5

|

|||

|

M6.0

|

18

|

12.4

|

(-0.7)

|

6.2

|

|||

|

M8.0

|

23

|

16.4

|

(-0.8)

|

7.7

|

|||

|

Screw Header Type

|

TRUSS

|

|

|

|

|||

|

Specifications

|

d2

|

d1/ (Tol.)

|

|

m (Tol.)

|

|||

|

M2.0

|

12

|

4.5

|

(-0.4)

|

2.2

|

|||

|

M2.2

|

12

|

5

|

(-0.4)

|

2.3

|

|||

|

M2.3

|

12

|

5.2

|

(-0.4)

|

2.3

|

|||

|

M2.5

|

12

|

5.7

|

(-0.4)

|

2.5

|

|||

|

M2.6

|

12

|

5.9

|

(-0.4)

|

2.6

|

|||

|

M3.0

|

12

|

6 9

|

(-0.5)

|

3.5

|

|||

|

M3.5

|

12, 14

|

8.1

|

(-0.5)

|

4

|

|||

|

M4.0

|

12, 18

|

94

|

(-0.5)

|

4.3

|

|||

|

M4.5

|

18

|

10.6

|

(-0.6)

|

4.7

|

|||

|

M5.0

|

18

|

11.8

|

(-0.6)

|

5

|

|||

|

M6.0

|

23

|

14

|

(-0.7)

|

6.2

|

|||

|

M8.0

|

23

|

17.8

|

(-0.8)

|

7.7

|

|||

|

Screw Header Type

|

PAN

|

|

|

|

|||

|

Specifications

|

d2

|

d1/ (Tol.)

|

|

m (Tol.)

|

|||

|

M2.0

|

12

|

3.5

|

(-0.4)

|

2.2

|

|||

|

M2.2

|

12

|

4

|

(-0.4)

|

2.4

|

|||

|

M2.3

|

12

|

4

|

(-0.4)

|

2 4

|

|||

|

M2.5

|

12

|

4.1

|

(-0.4)

|

2.6

|

|||

|

M2.6

|

17

|

4.5

|

(-0.4)

|

2.6

|

|||

|

M3.0

|

12

|

5.5

|

(-0.5)

|

3.6

|

|||

|

M3.5

|

12, 14

|

60

|

(-0.5)

|

3.9

|

|||

|

M4.0

|

12, 14

|

7

|

(-0.5)

|

4.2

|

|||

|

M4.5

|

14

|

8

|

(-0.6)

|

4.6

|

|||

|

M5.0

|

14, 18

|

9

|

(-0.6)

|

4 0

|

|||

|

M6.0

|

18

|

10.5

|

(-0.7)

|

6.3

|

|||

|

M8.0

|

23

|

14

|

(-0.8)

|

7.7

|

|||

In view of the limited content on the page, the above only shows our second punches for the JIS machine screws dimension table. Actually, here you can order and buy punches for the cold heading fasteners with slots of standards JIS, JCIS, ANSI, DIN, and ISO. In addition, we implement punches made by the customer's drawings.

Applications

Punches are widely used in the marking, stamping and extrusion of screw head slots, screws, self-tapping threads and other materials in the hardware industry.

More Details

Our Company

FAQ

Q1: Are you a manufacturer or trading company?

We are a manufacturer of tungsten carbide products.

Q2: Where is your factory located?

We are located in Zhuzhou city, Hunan province where is 2 hours-driving from Changsha airport

Q3: Is the price Competitive?

UKO offers reliable products at a good price.

Q4: Are the products High Quality?

Yes. The raw material will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Q5: How to place an order of tungsten carbide products?

1. Fill your Order List in our online Inquiry System.(Also you can directly contact our salesperson by E-mail / Skype / Whats App)

2. within 24-hours feedback when receiving your message.

Q6: How we can trust your company?

We support Alibaba trade insurance, 100% products quality protection, 100% on-time shipment protection, 100% payment protection for your covered amount.

Q7: What’s your delivery time?

For the normal type which we have mold it takes two weeks after receiving the advance payment.

For the non standard which we do not have mold it takes 4 to 6 weeks when receiving the advance payment.

Q2: Where is your factory located?

We are located in Zhuzhou city, Hunan province where is 2 hours-driving from Changsha airport

Q3: Is the price Competitive?

UKO offers reliable products at a good price.

Q4: Are the products High Quality?

Yes. The raw material will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Q5: How to place an order of tungsten carbide products?

1. Fill your Order List in our online Inquiry System.(Also you can directly contact our salesperson by E-mail / Skype / Whats App)

2. within 24-hours feedback when receiving your message.

Q6: How we can trust your company?

We support Alibaba trade insurance, 100% products quality protection, 100% on-time shipment protection, 100% payment protection for your covered amount.

Q7: What’s your delivery time?

For the normal type which we have mold it takes two weeks after receiving the advance payment.

For the non standard which we do not have mold it takes 4 to 6 weeks when receiving the advance payment.

Hot Searches