- Product Details

- {{item.text}}

Quick Details

-

Process:

-

Investment Cast Process

-

Service:

-

Casting +Machining(if Need)+surface Treatment

-

Material:

-

Steel

-

Size:

-

Customer's 2D/3D Drawing

-

MOQ:

-

Small Orders Accepted

-

Quality Control:

-

100% Inspection

-

Lead Time:

-

45 Days

-

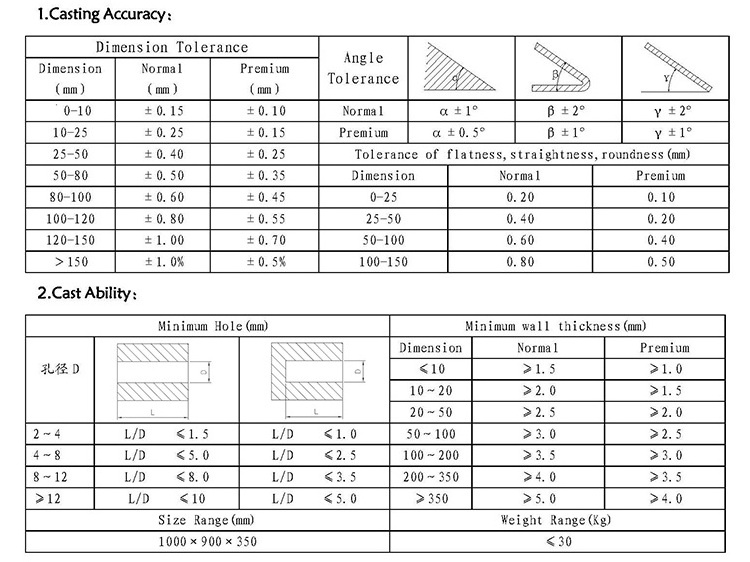

Casting Tolerance:

-

ISO 2768 - MK

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

OEM

-

Model Number:

-

Nonstandards

-

Process:

-

Investment Cast Process

-

Service:

-

Casting +Machining(if Need)+surface Treatment

-

Material:

-

Steel

-

Size:

-

Customer's 2D/3D Drawing

-

MOQ:

-

Small Orders Accepted

-

Quality Control:

-

100% Inspection

-

Lead Time:

-

45 Days

-

Casting Tolerance:

-

ISO 2768 - MK

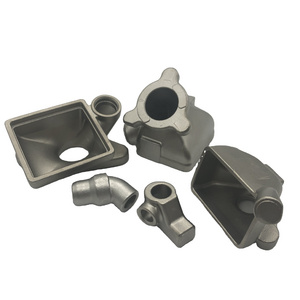

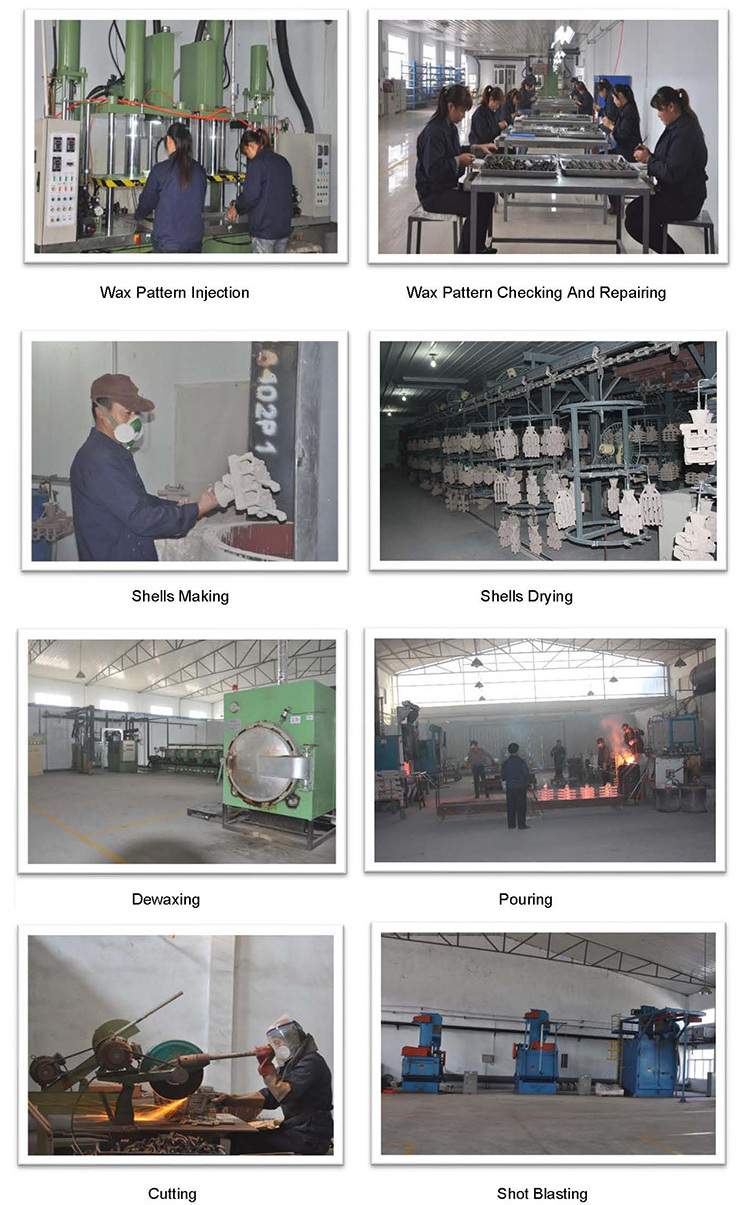

Investment casting, also known as lost wax casting, is a metalworking process that has been around for thousands of years. It is a highly precise and versatile casting method that is used to create intricate and complex shapes that are difficult to produce by other methods. In investment casting, a wax pattern of the desired shape is created and then coated with a ceramic material to form a shell. The wax is melted out of the shell, leaving a hollow cavity that is then filled with molten metal to create the final casting.

At our company, we specialize in investment casting using the silica sol shell technology. We produce precision castings of stainless steel, aluminium,brass or bronze. Our products are widely used in various industries such as automobiles, ships, construction, medical equipment, food machinery, and pipeline valves.

One of the primary benefits of investment casting is its accuracy and detail. Parts can be made with tight tolerances and high surface finishes, leading to less need for machining or other post-casting processes. Additionally, the process allows for the production of parts with complex geometries, thin walls, and intricate details that would be difficult or impossible to achieve with other casting techniques.

In terms of materials, investment casting can be used with a wide variety of metals and alloys. Stainless steel and aluminum are particularly popular materials due to their strength and durability, but investment casting can be used for essentially any metal that can be melted. The process also has the advantage of being able to cast multiple parts at once, which reduces production time and costs.

At our company, we are committed to delivering high-quality precision castings to our customers. Our investment casting process is guided by strict quality control measures to ensure that every part meets our customers' exacting standards. We are proud to have satisfied customers across the United States, Europe, and Asia, and we continue to strive for excellence in our products and services.

In summary, investment casting is a versatile and precise casting method that is ideal for producing complex parts with tight tolerances and high surface finishes. At our company, we specialize in investment casting using the silica sol shell technology, and produce precision castings of stainless steel, carbon steel, alloy steel, and other iron-based alloys. We are committed to delivering high-quality products to our customers and are proud to serve industries around the world.

================== INVESTMENT CASTING ==================

Our factory supply OEM services(custom service) in precision investment casting , which are also called lost wax casting , We have been committed to this technique for over 10 years . Our specialized engineer can provide you the full-service of technology advice and products improving projection,and also reduce the cost of the parts.

- Common Material

|

Stainless steel casting: |

304(CF8) , 316(CF8M) , 420 , 431 , 17-4PH , 2205 |

|

Alloy steel casting: |

42CrMo , 4140 , 8260 |

|

Carbon steel casting: |

1020 , 1045 , C45 , S235JR |

|

Bronze and Brass casting: |

H62 , CuZn38 , AB2 |

|

Aluminum casting: |

AL101 , ZL114A |

- Processing Ability

|

Surface finish: |

Ra1.6-Ra3.2 |

|

Size tolerance: |

VDG P690 D2 |

|

Maximum size: |

≤1200mm×800mm×400mm |

|

Weight range: |

0.1Kg-120Kg |

- Workshop

A

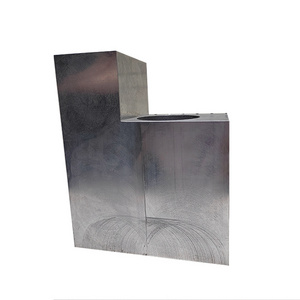

================== MACHINING ==================

|

l Drilling And Tapping |

l CNC Turning |

|

l Reaming |

l CNC Milling |

|

l Honing |

l Wire EDM |

We provide a full range of quality inspection to meet your requirement. It includes:

|

l Chemical Composition Inspection(Spectral Analysis) |

l X-ray Inspection |

|

l Mechanical Property Inspection |

l Magnetic Power Inspection |

|

l Metallographic Analysis |

l Ultrasonic Flaw Detection |

|

l Coordinate Measuring Machine (CMM) |

l Dye Penetration Inspection |

|

l Roughness Measurement |

l Salt Spray Test |

================== Product Examples ==================