- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Carton Box

-

Weight:

-

17kg

-

Power:

-

1.1KW, 1.1kw

-

Weight (KG):

-

17 kg

-

Name:

-

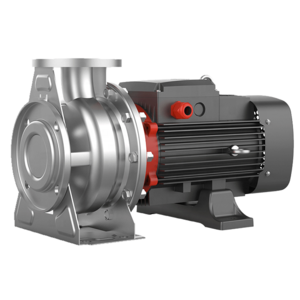

Self Priming Gas Liquid Mixing Pump

-

Voltage:

-

380V

-

Frequency:

-

50Hz

-

Capacity:

-

3 m3/h

-

Head:

-

10m ~ 70m

-

Liquid Temperature:

-

-15℃~+140℃

-

Maximum Ambient Temperature:

-

+40℃

-

Gas-Liquid Ratio:

-

about 1:9 (inspiratory volume is 8-10%)

Quick Details

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Xr

-

Material:

-

Carton Box

-

Weight:

-

17kg

-

Power:

-

1.1KW, 1.1kw

-

Weight (KG):

-

17 kg

-

Name:

-

Self Priming Gas Liquid Mixing Pump

-

Voltage:

-

380V

-

Frequency:

-

50Hz

-

Capacity:

-

3 m3/h

-

Head:

-

10m ~ 70m

-

Liquid Temperature:

-

-15℃~+140℃

-

Maximum Ambient Temperature:

-

+40℃

-

Gas-Liquid Ratio:

-

about 1:9 (inspiratory volume is 8-10%)

1.1KW 380V 50Hz Self Priming Pond Lake Purification Machine Impurities Removing Pump Aquaculture Water Treatment Pumps

Friendly reminder: We support customizing water pumps with special voltages, if necessary, please contact customer service! (Example: 100V 60Hz, 110V 60Hz, 120V 60Hz, 127V 60Hz, 220V 60Hz, 230V 60Hz, 240V 60Hz, 380V 60Hz, 415V 60Hz, 480V 60Hz, etc.)

|

Type: Self Priming Pump |

|

Name: Gas-Liquid Mixing Micro Bubble Generator |

|

| Power: 0.25KW, 0.55KW, 0.75KW, 1.1KW, 1.5KW, 2.2KW, 3.0KW | |

|

Voltage: |

|

| Frequency: | |

|

Capacity: |

|

| Capacity : | |

|

Head: |

|

|

Liquid Temperature: -15℃~+140℃ |

|

|

Maximum Ambient Temperature: +40℃ |

|

|

Gas-Liquid Ratio: about 1:9 (inspiratory volume is 8-10%) |

|

|

Series: Fish Pond Water Plant Breeding Aeration Pump |

|

|

Usage: |

|

|

Style: Hybrid Oxygen Pump |

|

|

Feature: |

|

|

Applicable Industries: Farms, Retail, Environmental Protection, Aquaculture |

| Water Pump Power | Voltage | Head (m) | Flow Rate (L/H) | Inlet and Outlet Diameter |

| 0.25KW | 220V | 40 | 200 | 3/8" (DN10) |

| 0.55/0.75KW | 220/380V | 40 | 1000 | 1" (DN25) |

| 1.1KW | 380V | 40 | 3000 | 1" (DN25) |

| 1.5KW | 220/380V | 40 | 3000 | 1" (DN25) |

| 2.2KW | 380V | 40 | 4000 | 1" (DN25) |

| 3.0KW | 220/380V | 40 | 6000 | 1-1/2" (DN40) |

1. Thin, clean, low-viscosity liquid;

2. Liquid temperature: -15℃ to +140℃;

3. The highest ambient temperature: +40℃;

4. The gas-liquid ratio is about 1:9 (inspiratory volume is 8-10%);

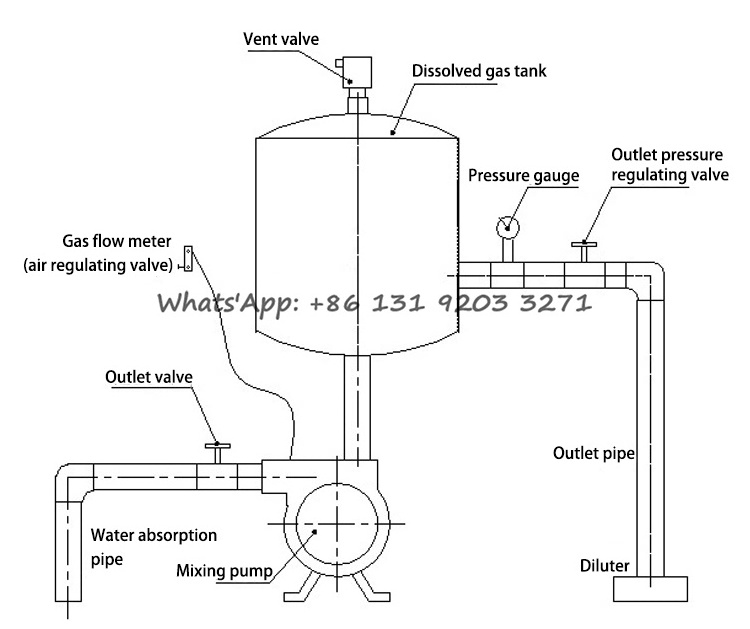

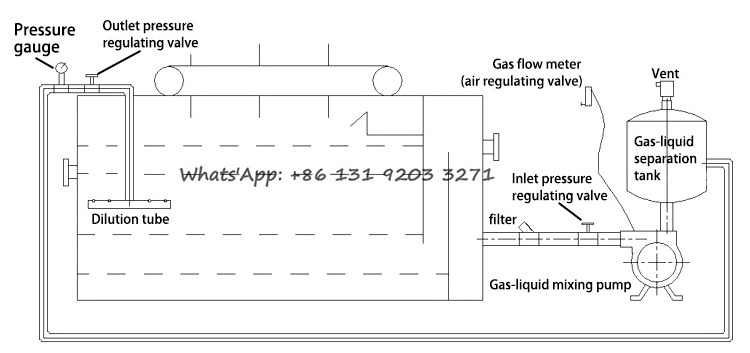

1. Inhale while sucking water, pressurize and mix in the pump, and the fine bubbles are 20-30 microns.

2. High gas-liquid dissolving efficiency, stable performance, easy operation and easy maintenance.

3. The air flotation device can replace pressurized pumps, air compressors, high-pressure dissolved air tanks, gas-water mixers and release heads, etc., to overcome the problems of unstable operation of traditional devices and large bubbles toppling.

4. The ozone water production device can replace booster pumps, large-scale oxidation towers, etc., with a gas-liquid dissolution efficiency of more than 90%, which is 2-4 times higher than that of a Wen-type mixer, greatly reducing equipment investment and operating costs.

1. Dissolved air flotation treatment equipment (various types of air flotation devices).

2. Ozone water production equipment (sterilization and preservation of pure drinking water, deodorization and decolorization of sewage to reduce COD, BOD, etc.).

3. Oxygen-enriched water production equipment (oxygen-enriched drinking water, intensive fish and turtle breeding, hydroponic cultivation, etc.), and can also be used for the production of other gas-liquid mixed functional water such as nitrogen.

4. Biochemical aeration equipment (domestic sewage, various industrial wastewater).

1. Air flotation treatment equipment, ozone water production equipment, oxygen-enriched water production equipment, biochemical treatment equipment, etc.

2. Circulation transfer of heat and refrigerant from various temperature control devices.

3. Various filtering devices.

4. Suction or high-pressure transportation of low-viscosity liquids such as gasoline, diluents, and various solvents from underground storage tanks.

5. Spray treatment of clean water, purified water, food, chemical liquid, waste liquid, etc., used in demanding applications such as intermittent operation, and sharp changes in back pressure.

6. Take water samples from rivers or water storage tanks, and transfer foaming liquids. Liquids are sent in long horizontal pipelines that are prone to air pockets.