Raycus is largest manufacturer of laser source in China , can weld carbon steel , stainless steel and aluminium etc . Good quality

and long life . Suitablef for 24 hours continuous working.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

KNOPPO

-

Single Pulse Energy:

-

90J

-

Pulse Width:

-

0.3-20ms

-

Wavelength:

-

1064nm

-

Focal Spot Diameter:

-

0.1-2.0mm

-

Dimensions:

-

1.38*0.83*1.1m

-

Weight (KG):

-

300 KG

-

Core Components:

-

Laser Source

-

Model:

-

KW Series

-

Application:

-

Metal Stainless Steel Welding

-

Laser wavelength:

-

1064nm Laser Welding

-

Laser source:

-

Raycus Brand

-

Advantage:

-

Welding Precision

-

Power Supply:

-

220±20% VAC 50/60Hz

-

Welding materials:

-

Metallic Material

-

Cooling method:

-

Water Cooliing

-

Water chiller:

-

S&A

-

Product name:

-

Handheld fiber laser welding soldering machine price

Quick Details

-

Max. Output Power:

-

2000W

-

Use:

-

welding advertising letters

-

Laser Source Brand:

-

Raycus

-

Place of Origin:

-

China

-

Brand Name:

-

KNOPPO

-

Single Pulse Energy:

-

90J

-

Pulse Width:

-

0.3-20ms

-

Wavelength:

-

1064nm

-

Focal Spot Diameter:

-

0.1-2.0mm

-

Dimensions:

-

1.38*0.83*1.1m

-

Weight (KG):

-

300 KG

-

Core Components:

-

Laser Source

-

Model:

-

KW Series

-

Application:

-

Metal Stainless Steel Welding

-

Laser wavelength:

-

1064nm Laser Welding

-

Laser source:

-

Raycus Brand

-

Advantage:

-

Welding Precision

-

Power Supply:

-

220±20% VAC 50/60Hz

-

Welding materials:

-

Metallic Material

-

Cooling method:

-

Water Cooliing

-

Water chiller:

-

S&A

-

Product name:

-

Handheld fiber laser welding soldering machine price

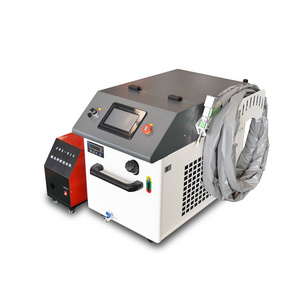

Fiber Laser Metal Welding Machine

Product Description

1. Introduction

* Fiber transmission laser welding machine coupled high energy laser beam into fiber cable,after long distance transmission , it is focusing on the work piece for welding by collimating lens collimate light.It adopts Germany technology, the overall appearance is good looking appearance,equipped with high performance bearingworking table,handheld type , simple operation and high cost ratio and good performance .With high efficiency and energy,100,000 hours lifetime,stable performance,high power,it is applicable and flexible for all kinds of laser industry.

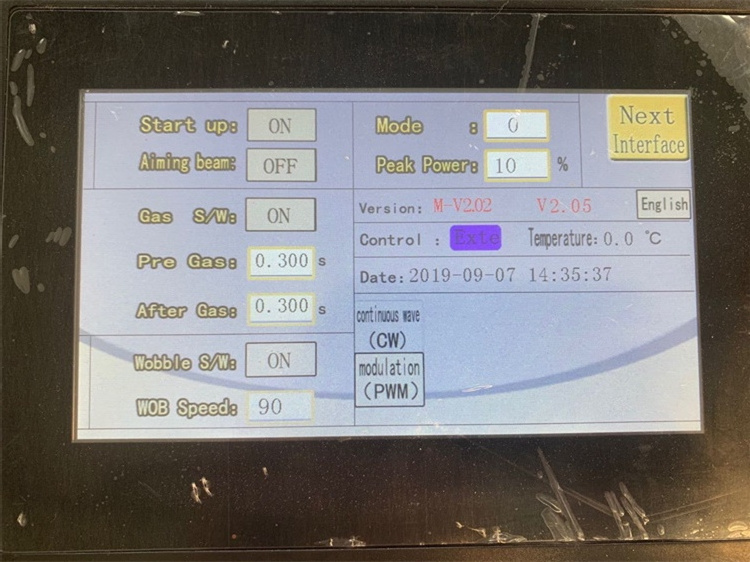

* Parameters small adjustments, choose different wave type for welding different materials, single and quick operation.

* Fiber transmission laser welding machine coupled high energy laser beam into fiber cable,after long distance transmission , it is focusing on the work piece for welding by collimating lens collimate light.It adopts Germany technology, the overall appearance is good looking appearance,equipped with high performance bearingworking table,handheld type , simple operation and high cost ratio and good performance .With high efficiency and energy,100,000 hours lifetime,stable performance,high power,it is applicable and flexible for all kinds of laser industry.

* Parameters small adjustments, choose different wave type for welding different materials, single and quick operation.

2. Product Features

A .Environmental protection

In traditional argon arc welding, considerations such as arc radiation, metal fume, and harmful gases make recruitment difficult. However, compared with fiber-optic handheld laser welding machines, it is easy to solve.

B .Portable design

Because handheld fiber laser welding machine uses the design of an integrated cabinet. Which integrates lasers, cooling devices, software control, etc. And has the advantages of small footprint, convenient movement, and powerful functions.

C .More convenient for operation

Now hand-held welding, using a hand-held welding gun instead of a fixed light path, is more convenient to operate.

The welding work piece has no deformation, no welding marks, and the welding is firm.

A .Environmental protection

In traditional argon arc welding, considerations such as arc radiation, metal fume, and harmful gases make recruitment difficult. However, compared with fiber-optic handheld laser welding machines, it is easy to solve.

B .Portable design

Because handheld fiber laser welding machine uses the design of an integrated cabinet. Which integrates lasers, cooling devices, software control, etc. And has the advantages of small footprint, convenient movement, and powerful functions.

C .More convenient for operation

Now hand-held welding, using a hand-held welding gun instead of a fixed light path, is more convenient to operate.

The welding work piece has no deformation, no welding marks, and the welding is firm.

|

SPECIFICATIONS FOR KW SERIES FIBER LASER WELDING MACHINE

|

|

|

|

|

||||

|

Model

|

|

KW-M

|

|

|

||||

|

Laser Wavelenth

|

|

1070nm

|

|

|

||||

|

Laser Power

|

|

1000W , 1500W , 2000W , 3000W

|

|

|

||||

|

Laser Source

|

|

RAYCUS / MAX

|

|

|

||||

|

Cooling Type

|

|

Water Cooling

|

|

|

||||

|

Welding Speed

|

|

0-120mm/s

|

|

|

||||

|

Welding Depth

|

|

0.1~10mm

|

|

|

||||

|

Fiber Cable Length

|

|

10m

|

|

|

||||

|

Auto Wire Feeder

|

|

Included

|

|

|

||||

Raycus Laser Source

-

Portable Design

Small footprint, convenient movement, and powerful functions.

Simple Control Panel

English Version , Easy to Operate .

Quality Laser Head

Light Weight , Easy to operate ; Good Quality , Long life .

Detailed Images

Main Features

The handheld laser welding machine is the preferred model in the metal material welding and processing industry.The machine can weld all kinds of metal. The welding seam is beautiful and firm, and the operation is simple, fast, flexible and low in processing cost. Fiber laser welding machine is to couple the laser beam to the optical fiber, after long-distance transmission, and then convert it into parallel light through collimating mirror, and finally focus on welding on the work-piece.

The non-contact method is adopted for the difficult parts of the optical fiber laser welding machine, and the welding mode is more flexible. Laser beam achieves the separation of time and energy, and multi-beam processing makes welding more accurate.

The handheld laser welding machine is the preferred model in the metal material welding and processing industry.The machine can weld all kinds of metal. The welding seam is beautiful and firm, and the operation is simple, fast, flexible and low in processing cost. Fiber laser welding machine is to couple the laser beam to the optical fiber, after long-distance transmission, and then convert it into parallel light through collimating mirror, and finally focus on welding on the work-piece.

The non-contact method is adopted for the difficult parts of the optical fiber laser welding machine, and the welding mode is more flexible. Laser beam achieves the separation of time and energy, and multi-beam processing makes welding more accurate.

Related Products

Packing&Shipping

Standard Wooden Box

After Sales Service

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Company Introduction

Knoppo Automation is one of the world’s leading manufacturers of high-tech industrial laser solutions, dedicated to providing laser intelligent equipment solutions and enabling our customers in various branches around the world to become more efficient and competitive. With more than 15,000 laser cutting systems in the market and a rapidly increasing global base, Knoppo Automation is in a favorable position to serve the international customer base, guaranteeing highest quality and shortest response times in already more than 100 countries. Our focus is on the innovation, continuous improvement and rapid development of technologies, all of which aim to increase efficiencies and flexibility, minimize costs while generating the highest levels of environmental friendliness and sustainability to our all benefit. We aim to provide key technologies and customized integration solutions for Industry 4.0 and smart factories, helping enterprises to make perfect use of the many opportunities arising in the digital age.

The product range not only comprises of flat sheet cutting systems in various designs and dimensions, but also of laser tube cutting systems, CO2 laser cutting engraving machine , laser marking machine etc . With our focused, highly skilled and experienced R & D team and a perfectly equipped and trained systematic after-sales technical department, we truly provide customer-oriented service experience.

The product range not only comprises of flat sheet cutting systems in various designs and dimensions, but also of laser tube cutting systems, CO2 laser cutting engraving machine , laser marking machine etc . With our focused, highly skilled and experienced R & D team and a perfectly equipped and trained systematic after-sales technical department, we truly provide customer-oriented service experience.

Contact Us

Hot Searches