vehicles.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office Building

-

Design Style:

-

Traditional

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XCGS

-

Model Number:

-

XCGS-FI

-

Type:

-

Heat Insulation Materials

-

Material:

-

Alu+Foam

-

Item:

-

Aluminum Foil Foam Insulation

-

Material Structure:

-

AL / Foam

-

Material Thermal Resistance:

-

0.24 (m2 K/W)

-

Normal Foam Thickness:

-

1-20mm ( can be customized)

-

Thermal Conductivity:

-

0.032W/mk

-

Silver side Emittance:

-

E0.03

-

Flammability Index:

-

Class 1/ Class A (AS/NZS 1530.2 - 1993)

-

Reflectivity:

-

96%-97%

-

Temperature range:

-

-50 degrees C to 80 degrees C

Quick Details

-

Warranty:

-

NONE

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

Others

-

Application:

-

Office Building

-

Design Style:

-

Traditional

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XCGS

-

Model Number:

-

XCGS-FI

-

Type:

-

Heat Insulation Materials

-

Material:

-

Alu+Foam

-

Item:

-

Aluminum Foil Foam Insulation

-

Material Structure:

-

AL / Foam

-

Material Thermal Resistance:

-

0.24 (m2 K/W)

-

Normal Foam Thickness:

-

1-20mm ( can be customized)

-

Thermal Conductivity:

-

0.032W/mk

-

Silver side Emittance:

-

E0.03

-

Flammability Index:

-

Class 1/ Class A (AS/NZS 1530.2 - 1993)

-

Reflectivity:

-

96%-97%

-

Temperature range:

-

-50 degrees C to 80 degrees C

Product Description

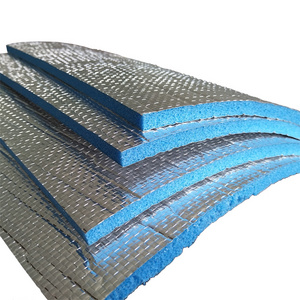

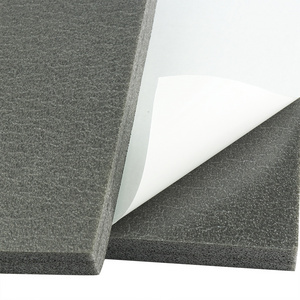

The product ( Air cell insulation/reflective aluminium foam foil insulation ) consists of two layers of aluminum foil with

foam laminated between the aluminum foil,provides excellent insulation: Reflects up to 97% of radiant energy in addition to resisting other types of heat transfer from conduction, convection and radiation. The two side aluminum foil forms an effective barrier against moisture, air currents and vapors.

foam laminated between the aluminum foil,provides excellent insulation: Reflects up to 97% of radiant energy in addition to resisting other types of heat transfer from conduction, convection and radiation. The two side aluminum foil forms an effective barrier against moisture, air currents and vapors.

|

Item

|

Thermal Aluminum Foil EPE/XPE Foam Insulation

|

|

|

|

|||

|

|

MPET+EPE/XPEMPET+EPE/XPE+MPET

Al+EPE/XPE Al+EPE/XPE+Al Al+woven+EPE/XPE+Al Al+woven+EPE/XPE+woven+Al Al+woven+EPE/XPE+Anti-glare+Al Al+EPE/XPE+Anti-glare+Al |

|

|

|

|||

|

Thickness

|

4mm 5mm 6mm 6.5mm 8mm or customzied

|

|

|

|

|||

|

Coating Color

|

Green, Blue, Orange or Customized

|

|

|

|

|||

|

MPET/Pure Aluminun Foil Thickness

|

12 micron/ 7 micron

|

|

|

|

|||

|

Product Thickness

|

1mm-20mm

|

|

|

|

|||

|

Reflectivity

|

96%~97%

|

|

|

|

|||

|

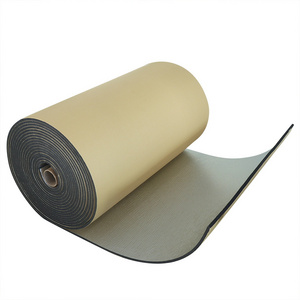

Normal Roll Size

|

1.2m*30m/Roll, 1.2m*40m/Roll,1.35m*22.25m/Roll,can be customized

|

|

|

|

|||

|

Pacakging

|

1 Roll /Clear Plastic Bag Or Customized Logo Printing Pacakging Bag Accept

|

|

|

|

|||

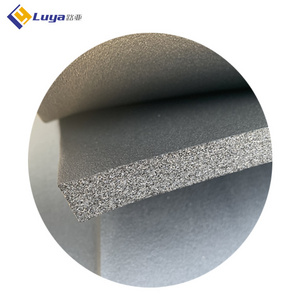

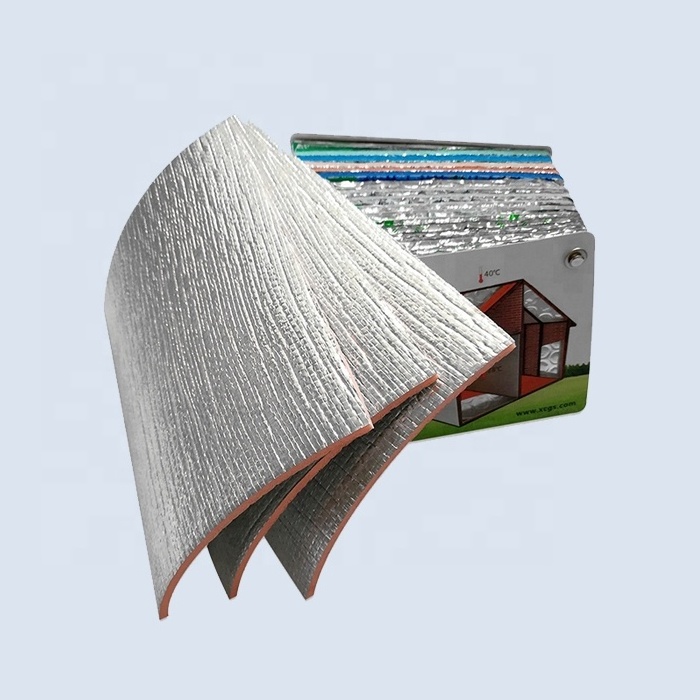

Details Images

Aluminium Foil Foam Insulation.

Reflective Foam Foil Insulation

Foam Insulation

Heat Foam Insulation

Custom Services

We can customize the bubble/foam foil insulaton material color, structure, bubble thickness as you need!

Application & Installation

Application

vehicles.

Installation Methods

1.Purchase approximately 10% more for overlapping and to provide the proper air gap between the purlins

2.Cover the metal roof purlins with double-sided adhesive tape. Unroll the foil wrap insulation and attach it to the first purlin.

3.Secure the bubble foil to the framing members with furring strips. Use a drill equipped with a screwdriver bit to drive the

screws into the framing members.

4.Cover the seams of the bubble insulation with foil tape.

2.Cover the metal roof purlins with double-sided adhesive tape. Unroll the foil wrap insulation and attach it to the first purlin.

3.Secure the bubble foil to the framing members with furring strips. Use a drill equipped with a screwdriver bit to drive the

screws into the framing members.

4.Cover the seams of the bubble insulation with foil tape.

Shipping & Delivery

Hot Searches