Features:

1. high quality stick steel plate to keep it is in stable operation .

2. service a long lifetime running with its stable design .

3. easy to operation and easy to maintain.

4. high efficiency

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

140kw

-

Weight:

-

1700 KG

-

Dimension(L*W*H):

-

2400*1950*1600 mm

-

Product name:

-

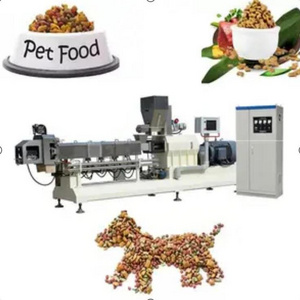

small dog food production line

-

Other name:

-

pet food production line

-

Capacity:

-

500-600kg/h dog food line

-

Operation:

-

Simple Automatic Operation

-

Motor Brand:

-

Siemens

-

Installation:

-

Offer manual book and engineer's guidance

-

Machine thickness:

-

2mm thicker than standard machine

-

need workers:

-

2 workers for small dog food line

-

Price:

-

Manufacturer's price

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Strongwin

-

Voltage:

-

380V/50Hz

-

Power:

-

140kw

-

Weight:

-

1700 KG

-

Dimension(L*W*H):

-

2400*1950*1600 mm

-

Product name:

-

small dog food production line

-

Other name:

-

pet food production line

-

Capacity:

-

500-600kg/h dog food line

-

Operation:

-

Simple Automatic Operation

-

Motor Brand:

-

Siemens

-

Installation:

-

Offer manual book and engineer's guidance

-

Machine thickness:

-

2mm thicker than standard machine

-

need workers:

-

2 workers for small dog food line

-

Price:

-

Manufacturer's price

Product Description

Customized Aquatic feed production lines, A variety of options for You to choose

Capacity:30kg/h-4t/h

Tell us what you needs, you can get the solution that suits you.

P.S. : Price is not fixed because of exchange rate and ocean freight ,pls contact supplier to get the newest price.

Advantages of our fish feed processing plant

1. The technological parameter, such as raw materials, temperature, and moisture, of this fish feed production plant is

adjustable. Floating fish feed produced by this plant have beautiful appearance, unique taste and rice-nutrient, suitable for

different fish and pets.

2. The fish feed pellet line is widely used in production of animal feed, such as dogs, cats, fish, foxes, birds and other pets.

3. floating fish feed plant adopts single-screw extruding technique. The fish feed pellet manufacturing process, from raw

materials crushing to finished products packaging, an be finished at one time.

4. All the fish feed machines in this plant are with stable operation and advanced technology. It can satisfy the production

demands of different customers on current market.

1. The technological parameter, such as raw materials, temperature, and moisture, of this fish feed production plant is

adjustable. Floating fish feed produced by this plant have beautiful appearance, unique taste and rice-nutrient, suitable for

different fish and pets.

2. The fish feed pellet line is widely used in production of animal feed, such as dogs, cats, fish, foxes, birds and other pets.

3. floating fish feed plant adopts single-screw extruding technique. The fish feed pellet manufacturing process, from raw

materials crushing to finished products packaging, an be finished at one time.

4. All the fish feed machines in this plant are with stable operation and advanced technology. It can satisfy the production

demands of different customers on current market.

Application:

After mixing, feed pellet extruder will compress feed powder into sized pellets. Strongwin fish feed production plant is the significant equipment with reliable performance, easy operation and cheap price, which is economic for small and medium scale production.

Therefore dry type feed pellet making machine are recommend in the feed pellet plant

widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation

Therefore dry type feed pellet making machine are recommend in the feed pellet plant

widely used for producing floating feed pellets of all kinds of aquatic animal, sinking and floating aqua-feed pellets both can be made just by adjusting feed formulation

Fish feed pellets dia. Is 0.9-15mm

How to Work

Technological procedure:

Starting Materials → mixing → transferring → extrusion puffing → transferring → drying → cooling → screening → spraying oil →seasoning → packaging

Equipment configuration

Mixer → transfer unit → extruder → elevator → dryer → cooler → vibrating screen → elevator → oil spraying machine → automatic

packaging machine

Technical Parameter

|

Strongwin 500-600 kg/h fish feed pellet plant

|

|

|

||

|

Main Machines

|

Power

|

Capacity

|

||

|

Feed Hammer Mill

|

22kw

|

500-700kg/h

|

||

|

Powder Mixer

|

4.0kw

|

200kg/batch,Time:15min

|

||

|

DGP120 Feed Extruder

|

Main power:55kw

Feeder Power:1.1kw

cutter power:1.5kw

|

500-600kg/h

|

||

|

Dryer

|

heating power:26-28kw;

fan power:0.75kw;

Mesh belt power:3.0kw

|

500-600kg/h

|

||

|

spraying machine

|

Host power: 0.75kw

Spreading power: 0.09kw

Pump power: 0.37kw

Output: 500-800kg/h

|

500-800kg/h

|

||

|

counter-current cooler

|

Fan power:4.0kw discharge method: pneumatic discharge

|

600-700kg/h

|

||

|

packing machine

|

Packaging efficiency: ≤300 bags/h

Packing range: 20-50kg/bag

|

≤300bag/h; 1-50kg/bag

|

||

|

Control System

|

|

|

||

|

Total Price

|

|

|||

Detailed Images

Feed Hammer Mill

Powder Mixer

The powder mixer machine is designed to meet the requirments: fertilizer,chemical,metallurgy,etc. The product has been widely used

in making organic fertilizer,chemical and the distribution systems in other industries .

The product services in the voltage of 380 V.The product has three parts:

(1)rack parts,

(2)the transmission connection part ,

(3) mix working part, including Nylon dowel pin shaft coupling

Different type has different performence. We can produce a new one according to your needs.

in making organic fertilizer,chemical and the distribution systems in other industries .

The product services in the voltage of 380 V.The product has three parts:

(1)rack parts,

(2)the transmission connection part ,

(3) mix working part, including Nylon dowel pin shaft coupling

Different type has different performence. We can produce a new one according to your needs.

Pet / Fish Feed Extruder

Dry type fish feed extruder is the significant equipment with reliable performance, easy operation and cheap price,

Application: widely used for producing variety materials into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc. The final products have unique shape and good taste, high nutrition and smooth textures.

Fish feed pellets dia. Is 0.9-15mm

Different moulds can be chosen to make pellets with different diameters and shapes.

Mesh-belt Type Fish Feed Dryer

Final pellets from fish feed extruder are moist in high temperature, so they can not be transported and stored immediately and

require to be dried first.

require to be dried first.

Characteristics:

1.High-efficiency and energy saving

2. Easy to install and maintain

3. Fast drying speed, high evaporation intensity

4. Convenient drying parameters adjustment, flexible operation, wide adaptation

5.Higher work capacity, the range of drying time is adjustable

Spray machine

For acquiring better smell and taste, the oil spraying machine can be used to spraying oil to the surface of fish feed pellets coming out of the dryer. It sprays atomized oil with high speed on the up and down surface of pellets, and the excessive oil can be recycled through filter.

Pellet Cooling

Hot pellets are soft and easily broken, which can result in a high percentage of fines. By cooling pellets can be harden. Counter flow cooler is cooling type that commonly used in pellet industry currently with the direction of the air and product of pellets in opposing directions.

Packing machine

capable for automatic quantitative batching packing of powder and pellet materials which are non-adhesive and have good flowing property.

Packaging efficiency: ≤300 bags/h

Packing range: 20-50kg/bag

Dimensions: 2750*950*2940mm

Weight: 586kg

Pictures from Our Customers

It is our pleasure to make it easy for customers to do business.

Related Products

Packing&Shipping

♥

Wooden or metal case according to specific size of each equipment, we twine thick plastic coating for each machine.

♥

Tight the equipment in the truck without space to ensure no rubbing during the transportation.

After Sales Service

7x24 hour Service

Strongwin Factory Can Provide Turnkey Feed Plant Project

Consultation Service → Design → Civil Engineering → Manufacturing→ Installation → Training

Customized Solutions

100% Quality Assurance

Support Oversea Installation

If you have any question, please contact us directly.

Company Introduction

Henan Strongwin Machinery Equipment Co.,Ltd is a joint-stock machinery manufacturing enterprise,integrating scientific reseach,production and making.Our company is located in the industy development Zone of Henan,China.

Our main products are feed pellet machine,feed pellet production line,fish feed extruder machine,pet food extruder machine and the production line.

Our company regards the product quality as the life of our company.All of our main machine motor is Siemens motor,the bearing is SKF bearing,the quality is very well.

Also We have passed relevant ISO,CE,SGS Certificate.Our machine are the recommended products in China machinery industry.We adopt highly materials and advanced processing technique,making the devices have long life and wearproof performance.Win a great reputation in domestic and abroad.

Corporate Culture

Strongwin Mission: Best machine for the world.

Strongwin Values: Customer first,teamwork,respect others,integrity,optimism and dedication.

Strongwin manufacturing guiding ideology: No one supervises us,but the God know everything.

Strongwin manufacturing basic principle: No labour saving though complicated processing,no material reduction though high cost.

Strongwin Manufacturing requirement: Build high-quality machinery with craftsman spirit.

Strongwin are your best consultant for feed pellet production line,if u have any demand,pls contact Strongwin people,we will give u the support on it.

FAQ

Q:i know little for feed machine and production line , what should i do ?

A:

please tell us your requirement, such as what kind of feed you want produce, the output you want per hour, how many raw materials you use and so on, we will design the flow diagram for you, and further our engineer will designer the whole feed factory for you depend on your site.

Q:our worker can not know how to operation the production line, what should i do?

A:

we has installation and after-sale service team,

our engineer can go to give customer installation guide. If customer need, our whole engineer team also go to customer's country.

Q:if the machine has a little mistake when produce and can not solve, what should i do?

A: please contact us immediately, by

email, WhatsApp,WEChat, or telphone

. Our worker will give you the solution.

Hot Searches