- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Energy conservation Environmental protection

-

Weight (KG):

-

3000 kg

-

Product Name:

-

Waste Gas Treatment Equipment

-

Application:

-

Waste Gas Purification

-

Usage:

-

Waste Gas Equipment

-

Function:

-

Pro-environment

-

Material:

-

Stainless Steel

-

Work Principle:

-

Change VOCs

-

Main function:

-

Waste Air Treatment

-

Application field:

-

Organic Exhaust Gas

-

Keyword:

-

Exhaust Gas Filtering System

Quick Details

-

Production Capacity:

-

Other

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Zhire custom

-

Marketing Type:

-

Energy conservation Environmental protection

-

Weight (KG):

-

3000 kg

-

Product Name:

-

Waste Gas Treatment Equipment

-

Application:

-

Waste Gas Purification

-

Usage:

-

Waste Gas Equipment

-

Function:

-

Pro-environment

-

Material:

-

Stainless Steel

-

Work Principle:

-

Change VOCs

-

Main function:

-

Waste Air Treatment

-

Application field:

-

Organic Exhaust Gas

-

Keyword:

-

Exhaust Gas Filtering System

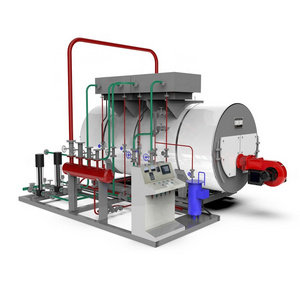

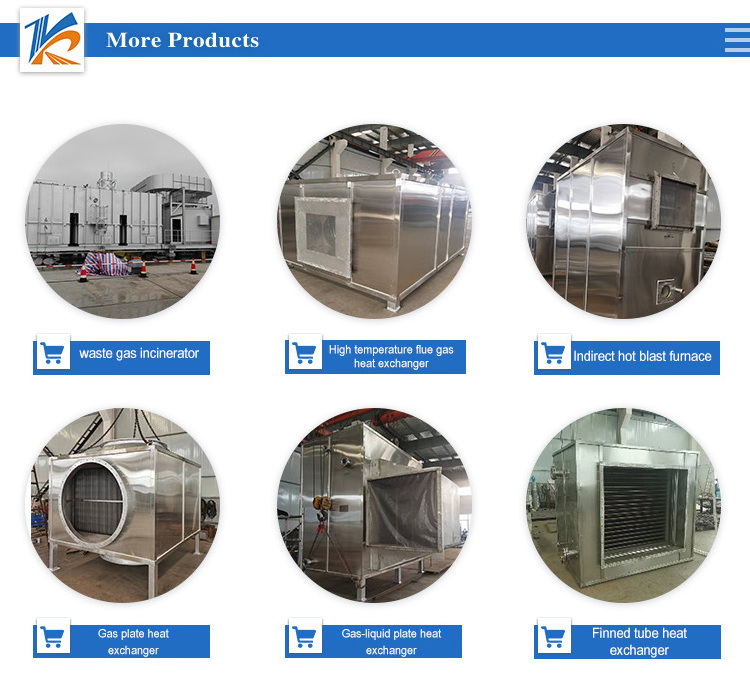

Catalytic incinerator (CO)

Catalytic combustion is the complete oxidation of organic matter with the help of catalyst at low temperature (200 ~ 400℃), which is a typical gas and solid phase catalytic reaction. In the process of catalytic combustion, the role of the catalyst is to reduce the activation energy of the reaction, while the reactant molecules are enriched on the surface of the catalyst to improve the

reaction rate. With the help of catalysts, organic waste gas can be flameless combustion under lower ignition temperature

conditions, and oxidation decomposition into CO2 and H2O, while releasing a lot of heat, mainly used in chemical industry, spray

painting, insulation materials, enameled wire, coating production and other industries.

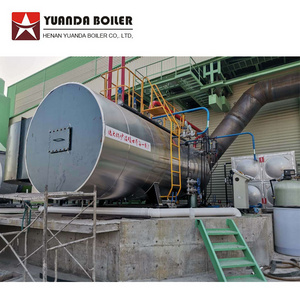

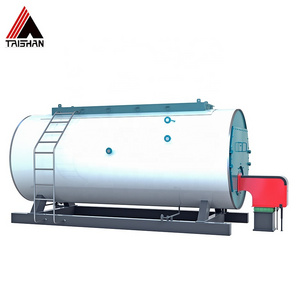

Direct combustion furnace (TO)

Direct-fired waste gas incinerator is to use the heat generated by the combustion of auxiliary fuel to raise the temperature of combustible harmful gases to the reaction temperature, so as to occur oxidation decomposition, and decompose the waste gas into carbon dioxide and water. Direct-fired waste gas incinerator is suitable for the waste gas treatment of spraying and drying equipment, and the purification of harmful gases emitted by petrochemical, pharmaceutical, painting and spray painting industries. At the same time, the direct-burning incinerator can also directly treat domestic waste, solid waste and industrial hazardous waste, and show its advantages in the gas purification of water-soluble or viscous substances and polymer substances in the organic waste gas. At the same time, the heat exchange equipment is added in the process design according to the need to preheat the waste gas that needs to be incinerated, so as to achieve the purpose of waste heat reuse and energy saving.

|

ITEM

|

2023 Hot Sell Environmental Protection Equipment Exhaust Gas Recovery Boiler Incinerator

|

Hot Searches