- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Silicon Carbide Desulfurization Nozzle

-

Usage:

-

Gas desulfurization denitration

-

Working temperature:

-

1380℃

-

SiC Content (%):

-

98%

-

Density:

-

3.02g/cm³

-

Open Porosity:

-

<0.1%

-

Feature:

-

High Thermal Conductivity,Low Thermal Expansion

-

Bending Strength:

-

250Mpa(20℃),280Mpa(1200℃)

-

Shape:

-

Vortex Nozzle

-

Customized service:

-

Acceptable

Quick Details

-

Weight (KG):

-

6

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZHIJING

-

Product name:

-

Silicon Carbide Desulfurization Nozzle

-

Usage:

-

Gas desulfurization denitration

-

Working temperature:

-

1380℃

-

SiC Content (%):

-

98%

-

Density:

-

3.02g/cm³

-

Open Porosity:

-

<0.1%

-

Feature:

-

High Thermal Conductivity,Low Thermal Expansion

-

Bending Strength:

-

250Mpa(20℃),280Mpa(1200℃)

-

Shape:

-

Vortex Nozzle

-

Customized service:

-

Acceptable

Products Description

Silicon Carbide Nozzle For Desulfurization

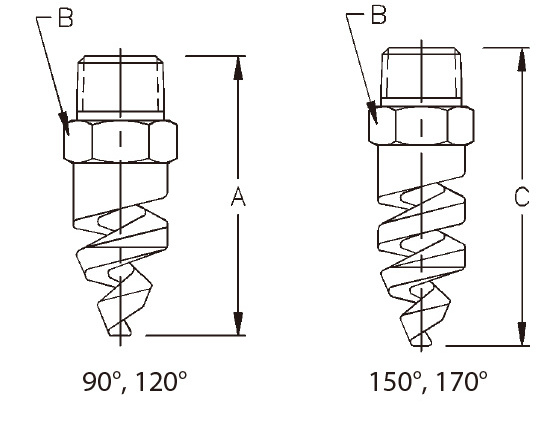

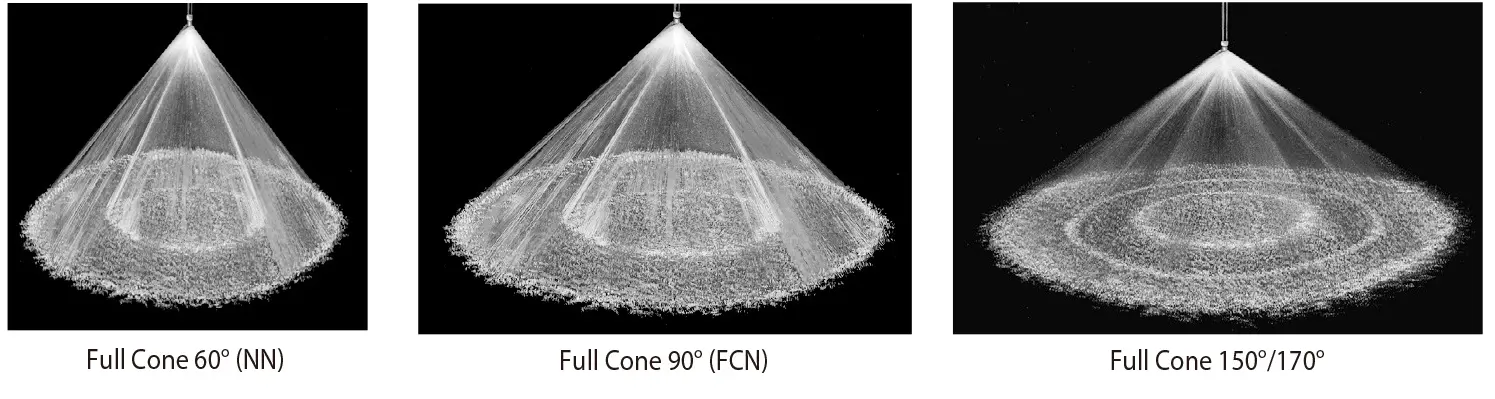

The RBSC/SiSiC spiral nozzle is a commonly used to desulphurization and dedust. It can produce hollow cone and solid cone spray shape with the spiral angle from 60 to 170 degrees. By cutting and colliding with the continuously smaller spiral body, the liquid will turn into the small liquid into the cavity of the nozzle. The design of the passage from the import to the exit is not obstructed by any blade and guide. In the case of the same flow, the maximum unblocked diameter of the spiral nozzle is more than 2 times that of the conventional nozzle. This can reduce the occurrence of hindrance to the greatest extent.

Silicon Carbide Nozzle Common Application:

1.Power plant, burning coal project desulfurization and denitration.

2. Air purification, air cooling and defoaming. 3.Evaporation, cooling, and dust controlling.

4. Wetting air by dust removing spray--environment protect.

5. Pre-treatment requires for non-blocking spray.

6. Air cooling.

7. Exhaust gas cleaning.

8. Fire fighting, fireproof.

9. Steel and iron/ petrochemical industry dustproof application

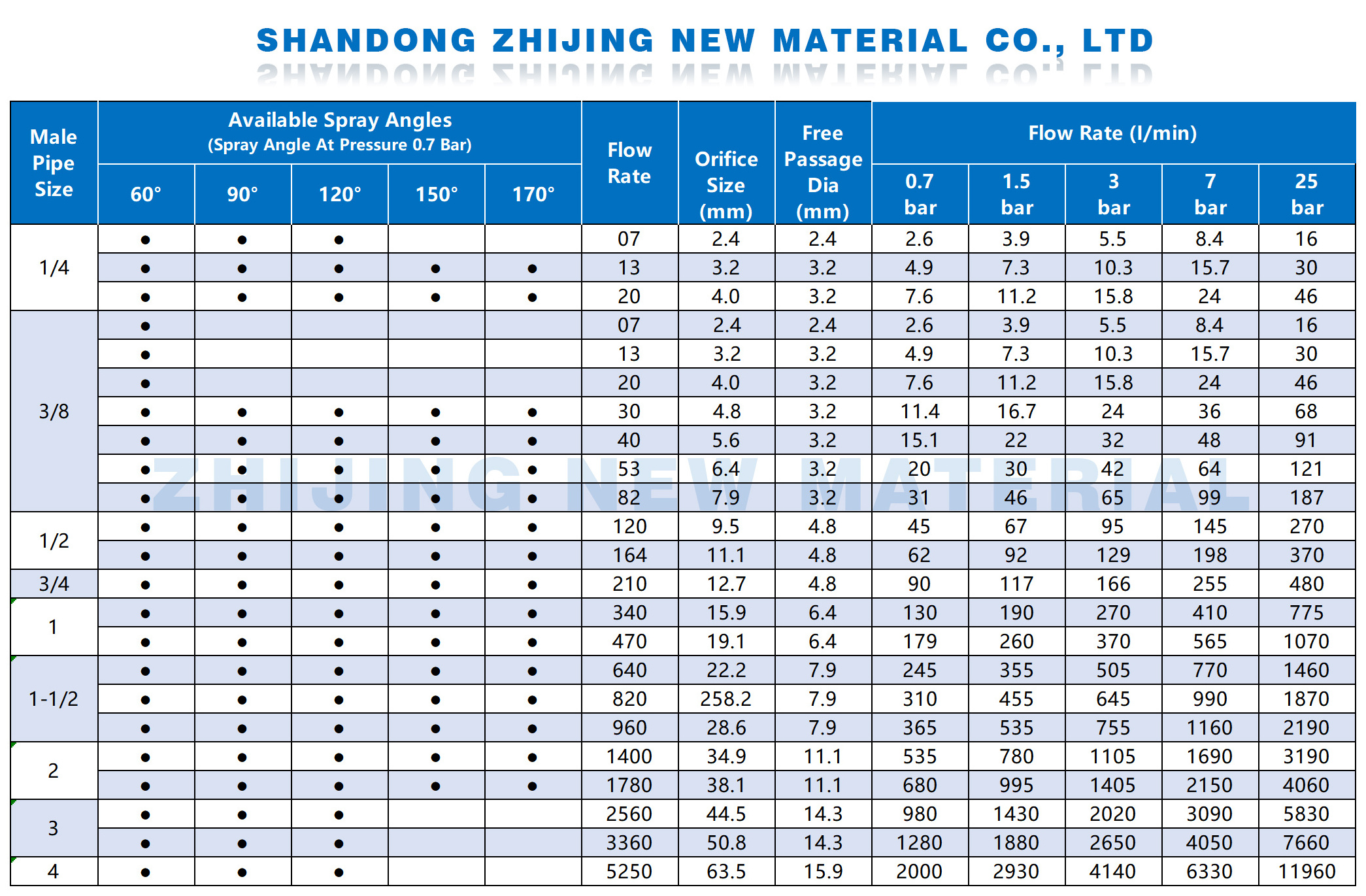

Specification

|

Product Name

|

Sisic Spiral Nozzle

|

|

|

|

|

|

|

|

|

||||||||

|

Spray Angle

|

60 degree

|

90 degree

|

120 degree

|

150 degree

|

170 degree

|

|

|

|

|

||||||||

|

Thread Size

|

1/4

|

3/8

|

1/2

|

3/4

|

1

|

1-1/2

|

2

|

3

|

4

|

||||||||

|

Flow Rate

|

5.5 to 4140 liters per minute @ 3 bar work pressure

|

|

|

|

|

|

|

|

|

||||||||

|

Material

|

Reaction-bonded Silicon Carbid

|

|

|

|

|

|

|

|

|

||||||||

|

Spray Pattern

|

full cone spray ; or hollow cone spray pattern customize

|

|

|

|

|

|

|

|

|

||||||||

|

Features

|

One-piece design, anti-clogging

|

|

|

|

|

|

|

|

|

||||||||

|

Application

|

For washing, rinsing, cooling tower ,desulfurization, dust control and fire protection;Desulfurization, denitrification, waste gas

washing, gas cooling, washing and bleaching process, fire prevention and extinguishing in power plants, coal-burning enterprises |

|

|

|

|

|

|

|

|

||||||||

Product Paramenters

Features

* High energy efficiency

* One-piece/no internal parts

* Clog-resistant performance

* High discharge velocity

* Male connection standard; female connection available by special order

* One-piece/no internal parts

* Clog-resistant performance

* High discharge velocity

* Male connection standard; female connection available by special order

Details Images

When a liquid with a certain pressure and speed flows from the top down to the RBSC/SiSiC spiral nozzle, the liquid in the outer part hits the helicoid with a certain angle on the nozzle. This can change the spray direction away from the nozzle. The included angle (helix angle) between the streamline of the surface of the cone of the different layers and the center of the nozzle is gradually reduced. It is conductive to increase the covering area of the ejected liquid effectively.

The silicon carbide spiral nozzle has excellent properties such as high strength, high hardness, strong corrosion resistance,severe wear, and high temperature resistance. It has a long service life under harsh conditions and is a key component of thermal power plants, large boilers, and complete sets of desulfurization and dust removal equipment. The spray droplets are evenly distributed, the flow path is unobstructed, and it completely replaces imported products.

Hot Searches