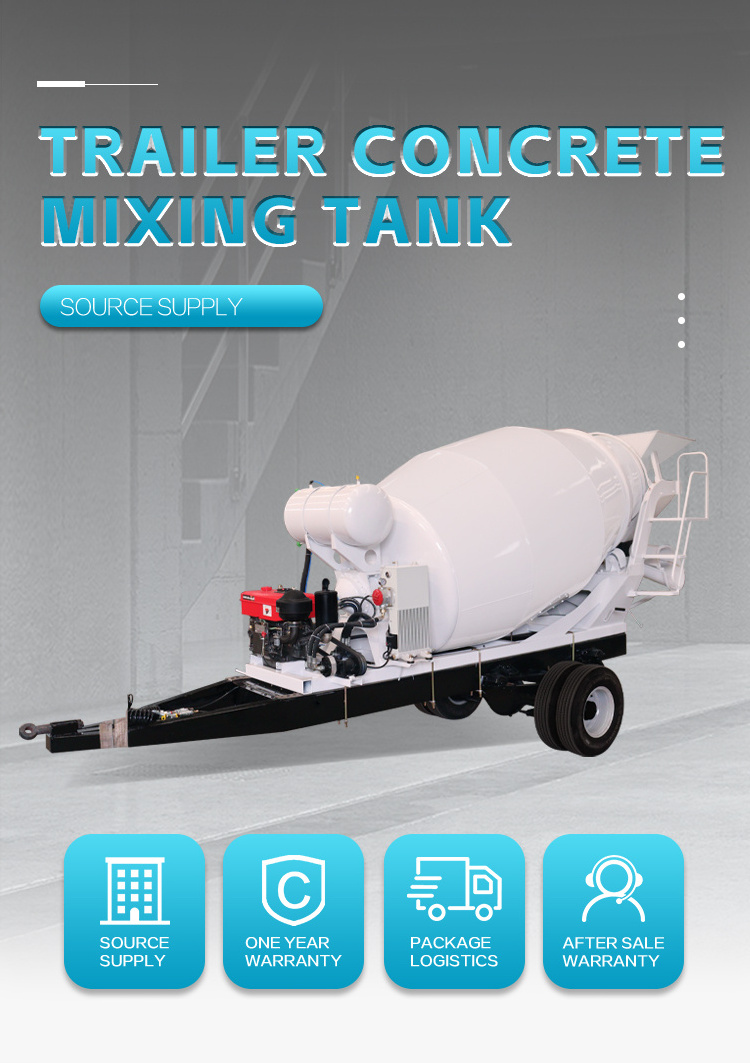

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

3000 kg

-

Dimension(L*W*H):

-

5400*2490*2450

-

Power:

-

24

-

Product name:

-

Concrete Mixer Tank

-

Driving type:

-

4 Wheel Driver

-

Engine:

-

Yuchai 4102 Turbo-charged

-

Model:

-

4m3 Concrete Mixer Tank

-

Drum mixing capacity:

-

4.0 CBM

-

Certification:

-

ISO CE

-

Hydraulic System:

-

USA SUNNY

-

Water tank volume:

-

250L

-

Productivity:

-

10-14m3/h

-

WHEEL BASE:

-

1800+3200mm+1350 Mm

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

wanshan

-

Weight:

-

3000 kg

-

Dimension(L*W*H):

-

5400*2490*2450

-

Power:

-

24

-

Product name:

-

Concrete Mixer Tank

-

Driving type:

-

4 Wheel Driver

-

Engine:

-

Yuchai 4102 Turbo-charged

-

Model:

-

4m3 Concrete Mixer Tank

-

Drum mixing capacity:

-

4.0 CBM

-

Certification:

-

ISO CE

-

Hydraulic System:

-

USA SUNNY

-

Water tank volume:

-

250L

-

Productivity:

-

10-14m3/h

-

WHEEL BASE:

-

1800+3200mm+1350 Mm

Product Overviews

Used Concrete Mixer Trailers

A concrete mixer or truck mixer is a large vehicle that is designed to mix and transport

concrete from one location to another. These trucks are commonly used in the construction industry for a variety of projects,including the construction of buildings, bridges, and roads. The use of concrete mixer trucks has revolutionized the construction industry, making it easier and more efficient to transport and mix large quantities of concrete.

One of the key benefits of using a concrete mixer truck is that it allows for consistent and high-quality concrete mixes. The mixing process in cement trucks is controlled by the operator, who can adjust the speed and rotation of the drum to ensure that the concrete is thoroughly mixed. This helps to prevent inconsistencies in the mix, which can lead to weak spots in the finished product.

concrete from one location to another. These trucks are commonly used in the construction industry for a variety of projects,including the construction of buildings, bridges, and roads. The use of concrete mixer trucks has revolutionized the construction industry, making it easier and more efficient to transport and mix large quantities of concrete.

One of the key benefits of using a concrete mixer truck is that it allows for consistent and high-quality concrete mixes. The mixing process in cement trucks is controlled by the operator, who can adjust the speed and rotation of the drum to ensure that the concrete is thoroughly mixed. This helps to prevent inconsistencies in the mix, which can lead to weak spots in the finished product.

Product structure

Products Description

Hydraulic system

Lower energy consumption.

Reliable action and good operating performance

Long service life

Reliable action and good operating performance

Long service life

Hydraulic oil radiator

Filter impurities

Exhaust air

Cooling down

Exhaust air

Cooling down

Power system

Different power diesel gasoline engine options Uniform mixing

Detachable support legs

Easy adjustable The Connector easy to connect to trucks pickup trucks Suitable for use in various venues

Various Models

|

Model

|

2 Cubic meters

|

4 Cubic meters

|

6 Cubic meters

|

8 Cubic meters

|

|||

|

Tank material

|

Carbon steel 235

|

|

|

|

|||

|

Tank thickness(mm)

|

6

|

|

|

|

|||

|

Tank dia.(mm)

|

1550

|

1750

|

2050

|

2200

|

|||

|

Antirust treatment

|

Shot blasting antirust treatment

|

|

|

|

|||

|

Tilt angle(°)

|

14

|

15

|

15

|

15

|

|||

|

Hydraulic system

|

ZHENJIANG

|

|

|

|

|||

|

Water supply(l)

|

200

|

200

|

350

|

400

|

|||

|

Discharge residual rate(%)

|

≤0.5%

|

|

|

|

|||

|

Mounting size(mm)

|

Customized

|

|

|

|

|||

|

Transportation size(mm)

|

3510*1550

*1780 |

4345*1750

*2215 |

4935*2050

*2365 |

5296*2200

*2532 |

|||

|

Weight(kg)

|

1300

|

1445

|

2260

|

3400

|

|||

Hot Searches