- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Pipe Production Line

-

Pipe Material:

-

Stainless Steel

-

Pipe shape:

-

Round Square Rectangle Pipe

-

Keyword:

-

tube Mill Welding Pipe Making Machine

-

Pipe Thickness:

-

1.5-5 mm

-

Welding type:

-

High Frequency Welded

-

Speed:

-

3-60 m/min

-

Certificate:

-

ISO9001/CE/BV

-

Usage:

-

Construction works

-

Function:

-

Stainless Steel Pipe Production Line

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TengTian

-

Weight (KG):

-

15000

-

Product name:

-

Pipe Production Line

-

Pipe Material:

-

Stainless Steel

-

Pipe shape:

-

Round Square Rectangle Pipe

-

Keyword:

-

tube Mill Welding Pipe Making Machine

-

Pipe Thickness:

-

1.5-5 mm

-

Welding type:

-

High Frequency Welded

-

Speed:

-

3-60 m/min

-

Certificate:

-

ISO9001/CE/BV

-

Usage:

-

Construction works

-

Function:

-

Stainless Steel Pipe Production Line

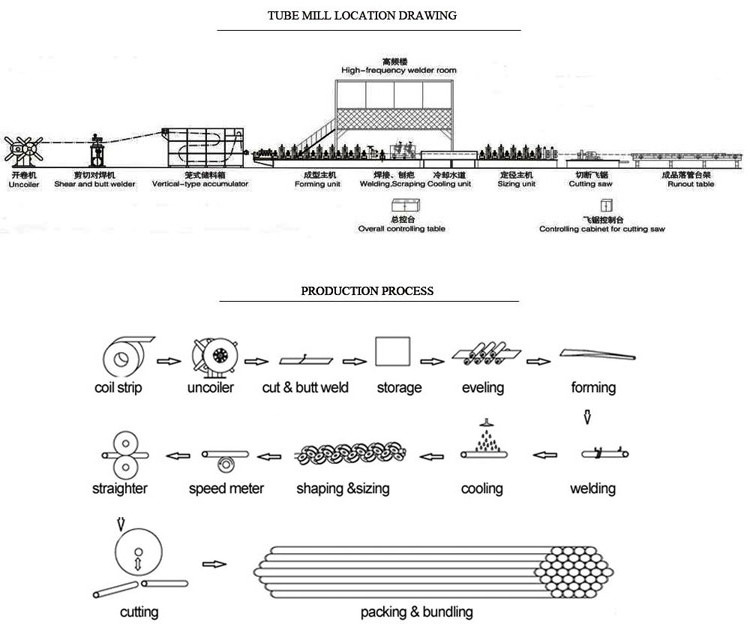

HG114

Material (steel coil)→uncoiler→ pinching and leveling →shear and welder→horizontal (or cage) accumulator→forming mill→HF soild welder→ external burr removing → IF annealing → heat treatment → air cooling → water cooling →sizing mill→rounghly straightening (turkey head)→cut off machine→run out table

-

Financial Responsibility to Our Clients

-

Superior Quality and Craftsmanship

-

Quality and Value to the Projects We Deliver

-

Highest Standards in Cost Control

-

On Time and on Budget

-

Real Focus on Customer Satisfaction

Q: What ’ s your nature of your company, a dealer or a factory?

A: We are manufacturer of tube mill forming equipment with our own factory.

Q: Which tube&pipe mill is right for me?

A: Tengtian works directly with our clients to determine the specification regarding their needs. Rest assured, we have the right product to meet the solutions you require. Big or small, a quick consultation will allow us to find the right fit!

Q:

How about the

welded pipe size

for

diameter

and

wall thickness

?

A:

The carbon steel pipe

diameter

can be customized from 25-606mm

with wall thickness

0.5- 25mm for different kinds of application.

Q: Where are you and how can I visit you?

A: Our factory is located in Shijiazhuang, Hebei province China. You can contact us before your visit so that we can arrange reception.

Q: Can you meet my budget?

A: With almost 10 years of experience we have been providing solutions to our clients with a wide range of budgets and monetary funding. Whether you have 1M or 100k, we can find the equipment to meet your budgetary requirements.

Q: What products your company is manufacturing?

A: Full Automatic Tube Mill, High-precision Welded Pipe Mill, Stainless Steel Pipe Production Line, Slitting Line, and other Auxiliary Equipment.

1. On-site training

Our technicians take part in the process of designing, building, assembling, commissioning, and maintaining the machinery with an emphasis on its efficiency, safety, and productivity. We will send our engineer s for the installation and deliver knowledge about the usage of the machinery as well as maintenance operations.

2. Maintenance and spare parts

We offer one - year quality guarantee and lifetime warranty. Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, we only charge the cost of the spare parts.

3. P re-sell and after-sell service

We supply the pre-sell and after-sell service. P re-sell service: workshop design, and production output design . A fter-sell service: installation , training and the skilled engineer s for working.

4. We can also sent the engineer s to work for you for serval months or 1 year. The engineer will help you to improve the output, reduce the waste and decrease the cost.

5. We supply the pre-sell service- d esign for the whole project of stainless steel pipe making or carbon steel pipe making.

6. We will be responsible for the loading and shipping . We assure that your machines will be delivered within promised time.