- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Removing Impurity and Dust

-

Production Capacity (kg/h):

-

500 - 800

-

Weight:

-

80 KG

-

Application:

-

Oil Seeds

-

Function:

-

Grain Size Separation

-

Product name:

-

Grain Vibratory Screen Separator

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

BTMA

-

Type:

-

Grain Seed Cleaner

-

Use:

-

Removing Impurity and Dust

-

Production Capacity (kg/h):

-

500 - 800

-

Weight:

-

80 KG

-

Application:

-

Oil Seeds

-

Function:

-

Grain Size Separation

-

Product name:

-

Grain Vibratory Screen Separator

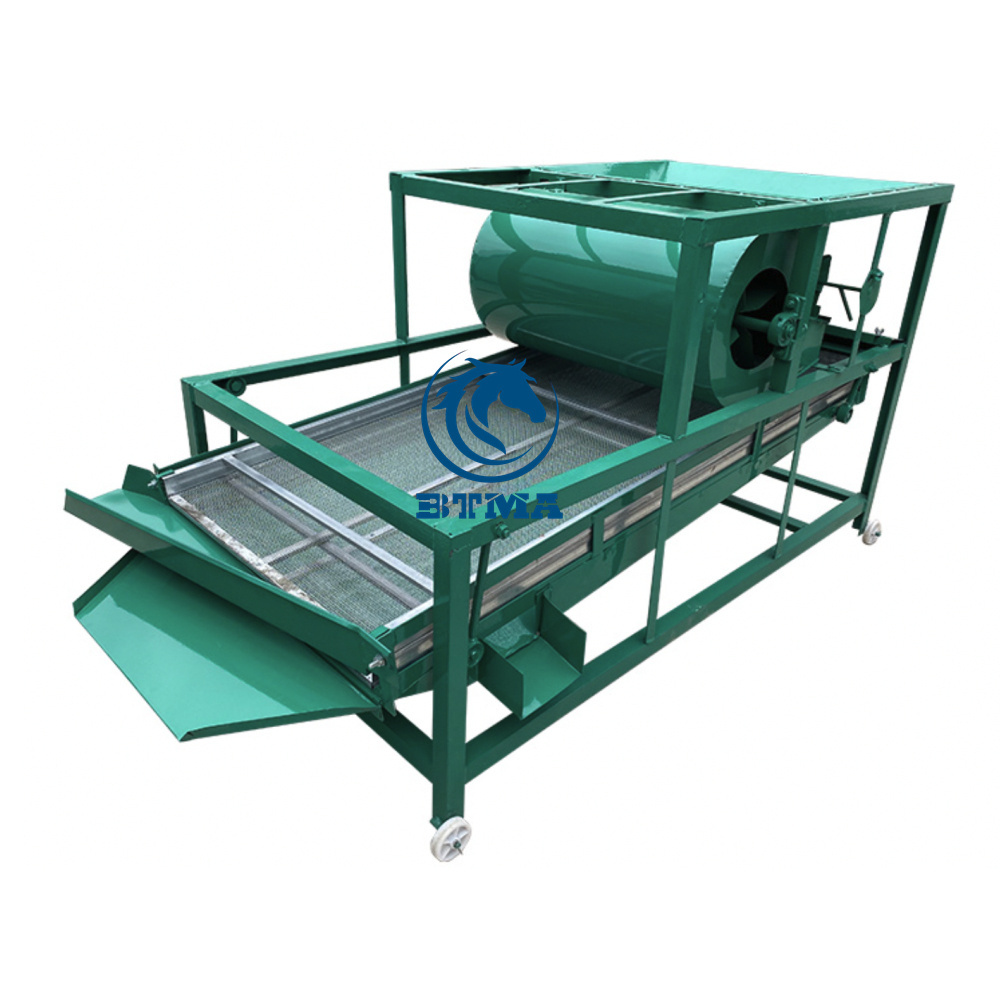

BTMA screen wheat grain winnower grain cycle vibrating cleaning screen air screen grain seed cleaner

Products Introduction

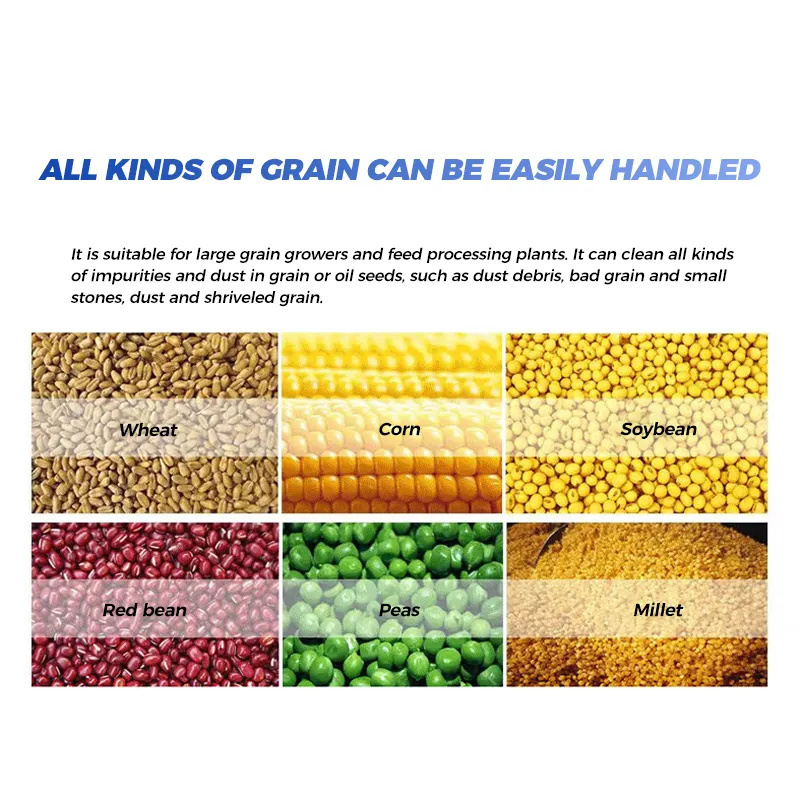

Grain screening machine is commonly used for selection, grading and impurity removal of wheat, rice, corn, soybean, cotton seeds and various oil seeds. It can removing impurities such as dust, crumbs, bad grains ,small stone. It is suitable for large grain growers, feed processing plants, and the vast number of large grain farmers.

Raw Materials

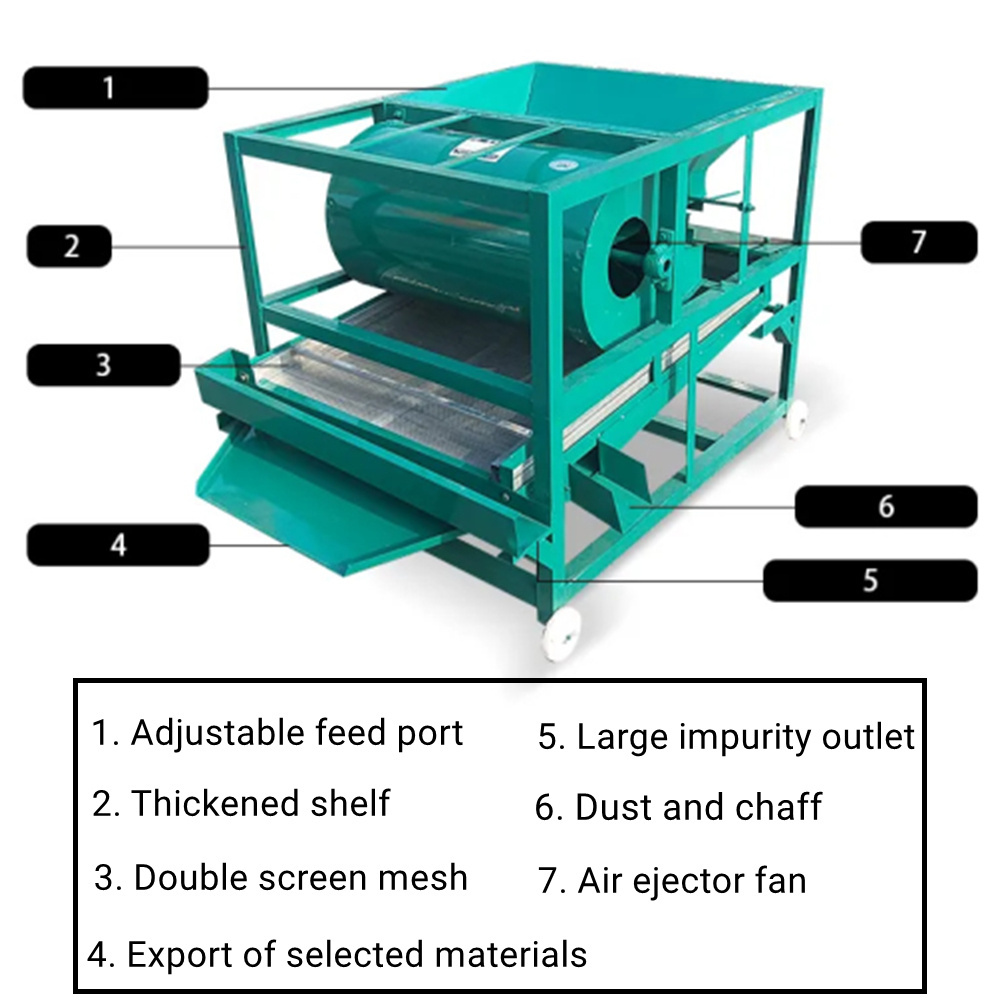

Structure And Working Principle

Working Principle

Product Paramenters

|

Model

|

Capacity

|

Power

|

Size

|

Weight

|

|

GS-700

|

500-800 KG/H

|

3KW/380V

|

1500*900*900(MM)

|

80KG

|

|

GS-900

|

1500-1800 KG/H

|

4KW/380V

|

2000*900*900(MM)

|

120KG

|

|

GS-1000

|

2500-2600 KG/H

|

4KW/380V

|

2000*1300*900(MM)

|

190KG

|

Our Advantages

There is no dust during cleaning, which greatly

changes the cleaning and screening environment. The screening rate of this machine reaches 98%.

It has an additional air-selection device, and it carries out material conveying and screening through screw conveying, which can improve the working environment,It has a good effect on reducing grain fur and dust pollution.

Details Images

Packing And Delivery

Packing

We will load different sizes of packing according to different machine sizes, and the normal packing is in wooden cases.

If exported to European countries, wood frame will be fumigation. If the container is too tight, we will use the PE film according to the customer's special requirements.

We will load different sizes of packing according to different machine sizes, and the normal packing is in wooden cases.

If exported to European countries, wood frame will be fumigation. If the container is too tight, we will use the PE film according to the customer's special requirements.

Delivery

Our goods are usually shipped from Qingdao port and transported by sea to the client's port.We are based on the actual

needs of customers, to carry out tailor-made sales. By senior engineer to design scheme, after receipt of customer deposits began production, regardless of the size of the equipment we can deliver the goods in two weeks, paid the balance before delivery.

needs of customers, to carry out tailor-made sales. By senior engineer to design scheme, after receipt of customer deposits began production, regardless of the size of the equipment we can deliver the goods in two weeks, paid the balance before delivery.

Certifications

Hot Searches