- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

203-492-7

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JITIAN

-

Model Number:

-

JT

-

Type:

-

one Component

-

Application:

-

Construction

-

Packing:

-

15KG/pail or OEM

-

Shelf life:

-

12 Months

-

Color:

-

White

Quick Details

-

CAS No.:

-

9006-65-9

-

Other Names:

-

Liquid Silicone Rubber

-

MF:

-

SiO(CH3)2N

-

EINECS No.:

-

203-492-7

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JITIAN

-

Model Number:

-

JT

-

Type:

-

one Component

-

Application:

-

Construction

-

Packing:

-

15KG/pail or OEM

-

Shelf life:

-

12 Months

-

Color:

-

White

Liquid silicone rubber injection molding gel for craft molds toy

Product Detail

| Application | Construction |

| Packing | 15KG/pail or OEM |

| Shelf life | 12 Months |

| Color | White |

| Product Keywords | liquid silicone rubber injection molding,liquid silicone rubber gel for craft molds,liquid silicone rubber for toy |

Liquid silicone rubber to make mold

Product Description

Description

H10 series is a kind of two part silicone rubber in addition cure or platinum cure type with mixing ratio of 1:1 or 100:1 . It can cure at room temperature as well as under heat . It’s a kind of food grade silicone and mainly used for mold making.

Application

H10 series silicone rubber is mainly used for making molds of concrete stone,GRC,polyurethane products ; wax, candle decoration ; rapid prototyping and tyre molds; chocolate,candy and similar products .

Technical Parameters

|

Model |

H1001 |

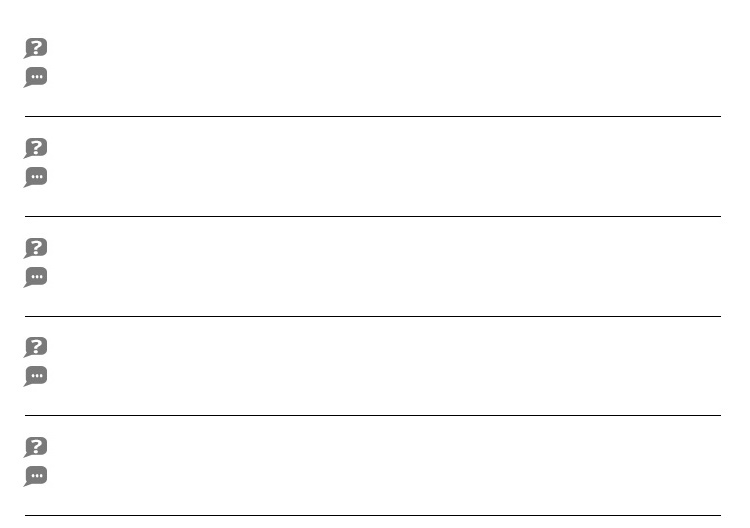

H1002 |

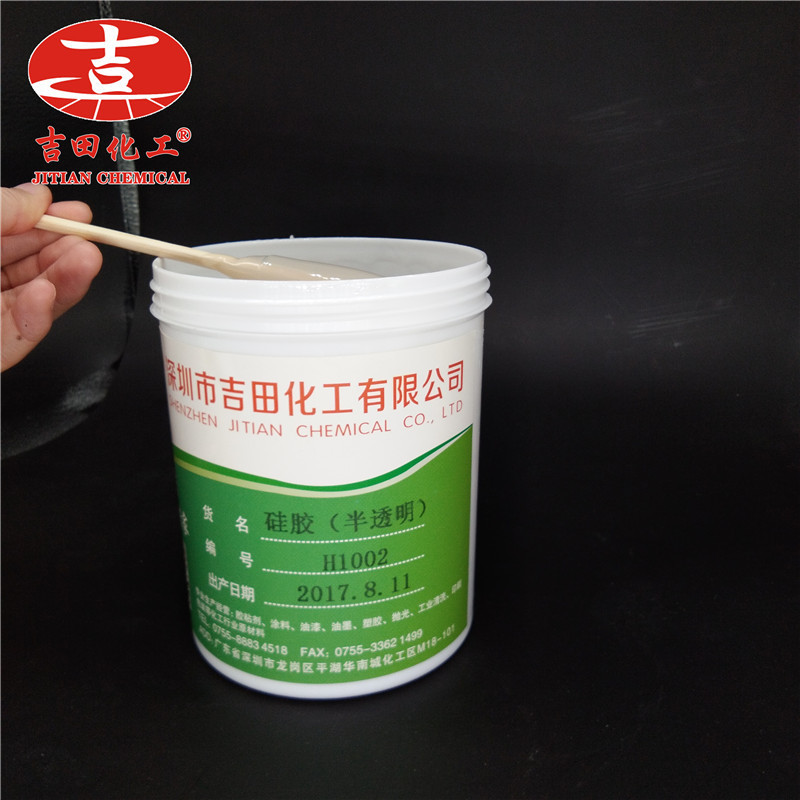

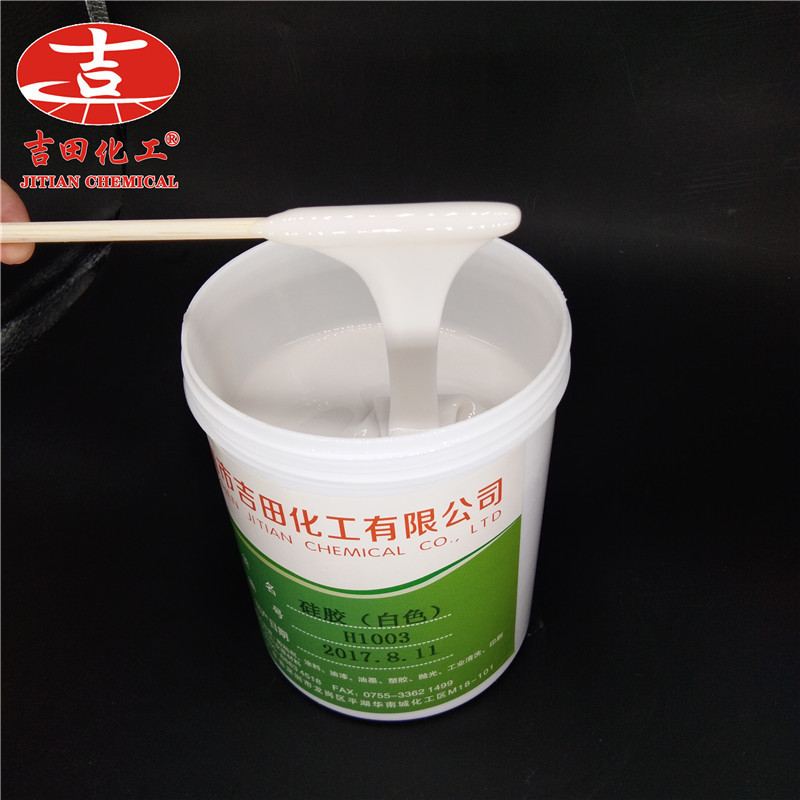

H1003 |

H1004 |

|

Color |

OEM |

Translucent |

white |

|

|

Mixing ratio (%) |

OEM |

100:2 |

100:2 |

1:1 |

|

Pot life (mins,under 25 ℃ ) |

OEM |

30-40 |

30-40 |

30-40 |

|

Curingtime |

OEM |

4-5(hrs under 25 ℃ ) 20-30 (mins under 60 ℃ ) |

4-5(hrs under 25 ℃ ) 20-30 (mins under 60 ℃ ) |

4-5(hrs under 25 ℃ ) 20-30 (mins under 60 ℃ ) |

|

Hardness( Shore A ) |

OEM |

30±2 |

30±2 |

30±2 |

|

Tensile-strength(MPa |

OEM |

7±1.0 |

7±1.0 |

7±1.0 |

|

Tear-strength (kN/m) |

OEM |

25±2 |

25±2 |

25±2 |

|

Viscosity (After A/B mixed ,mPa.s) |

OEM |

6500±1500 |

6500±1500 |

6500±1500 |

|

Shrinkage rate (%) |

OEM |

≤0.1% |

≤0.1% |

≤0.1% |

|

Elongation(%) |

OEM |

400% |

400% |

400% |

Characteristics

*An exceptional fluidity and good operability, easy to demold

*Good tensile and tear strength

*Outstanding bubble releasing

*Non-deformation

*Low shrinkage

*Aging resistance ,high temperature resistance (200 ℃ )

*Environmentally, food-grade

Operations

Step 1: prepare the original molds

Step 2: Take 100 G parts A and add 100 G or Take 100 G parts A and add 10 G parts B and mix them evenly.

Step 3: Vacuum pumping

Step 4: Pouring casting

*Notes:1. For simple pattern products we suggest use pouring operation way , which will be very easy to operate and demould. Pourable silicone require light viscosity which will be easy to flow smoothly and easy to de-air .

PACKAGE:

Standard export carton packing.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.