- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

1600

-

Dimension(L*W*H):

-

6000*3600*3700mm

-

Weight (T):

-

17 T

-

Range of Spindle Speed(r.p.m):

-

1 - 6000 r.p.m

-

Spindle Motor Power(kW):

-

15

-

Max. Table Load(kg):

-

5000 kg

-

Feed Speed(mm/min):

-

1 - 5000 mm/min

-

Rapid Feed Speed(m/min):

-

5

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

UnionTech

-

Voltage:

-

380V

-

Name:

-

GMC2016

-

Working travel:

-

2000*1600*800MM

-

Control system:

-

SIEMENS/SYNTEC/GSK/FANUC/Mitsubishi

-

Spindle:

-

15kw Mechanical spindle

-

Machine structure:

-

Cast iron

-

Guide rails:

-

HIWIN 55 for X, Y, Z axis

-

Motor:

-

FUNUC servo motor

-

Driver:

-

FUNUC servo driver

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Worktable size:

-

2000*1300mm

Quick Details

-

Table Size (mm):

-

2000*1300

-

Number of Axes:

-

3

-

Table Travel (X) (mm):

-

2000

-

Table Travel (Y) (mm):

-

1600

-

Dimension(L*W*H):

-

6000*3600*3700mm

-

Weight (T):

-

17 T

-

Range of Spindle Speed(r.p.m):

-

1 - 6000 r.p.m

-

Spindle Motor Power(kW):

-

15

-

Max. Table Load(kg):

-

5000 kg

-

Feed Speed(mm/min):

-

1 - 5000 mm/min

-

Rapid Feed Speed(m/min):

-

5

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

UnionTech

-

Voltage:

-

380V

-

Name:

-

GMC2016

-

Working travel:

-

2000*1600*800MM

-

Control system:

-

SIEMENS/SYNTEC/GSK/FANUC/Mitsubishi

-

Spindle:

-

15kw Mechanical spindle

-

Machine structure:

-

Cast iron

-

Guide rails:

-

HIWIN 55 for X, Y, Z axis

-

Motor:

-

FUNUC servo motor

-

Driver:

-

FUNUC servo driver

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Worktable size:

-

2000*1300mm

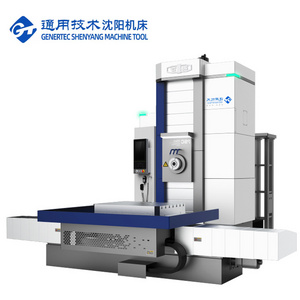

Heavy duty CNC 5 axis gantry milling GMC 2016 with big size boring machine Gantry Frame Structure Cnc 5 Axis Milling Machine

Gantry Machining center performance characteristrics

·

The gantry machining center is mainly used for processing large parts such as plates, discs, housing parts and molds with high precision, many processes and complicated shapes.

· GMC series gantry machining cneter adopts fixed beam double-column gantry frame structure, cross layout, and the machine tool is stable and reliable. The headstock adopts a nitrogen cylinder balancing mechanism to ensure the smoothness of the headstock moving up and down along the sliding saddle.

· The bed, workbench, column, beam, sliding saddle, headstock and other large parts are made of high-strength cast iron material, which is made of resin sand.

The two aging treatments eliminate stress and effectively inhibit the deformation and vibration of the machine tool caused by cutting force.

|

Project

|

Unit

|

GMC2013/3013

|

GMC2016/3016/4016

|

GMC2021/3021/4021

|

||

|

X axis travel

|

mm

|

2000/3000

|

2000/3000/4000

|

2000/3000/4000

|

||

|

Y axis travel

|

mm

|

1400

|

1600

|

2100

|

||

|

Zaxis travel

|

mm

|

800

|

|

|

||

|

Gantry width

|

mm

|

1400

|

1660

|

2150

|

||

|

Spindle end to table distance

|

mm

|

60-860

|

200-1000

|

200-1200

|

||

|

Workbence size (L*W)

|

mm

|

2000/3000*1000

|

2000/3000/4000*1300

|

2000/3000/4000*1800

|

||

|

Spindle revolution

|

rpm

|

6000

|

|

|

||

|

Spindle type

|

-

|

BT50

|

|

|

||

|

Spindle motor

|

rpm

|

15kw / 18.5kw

|

|

|

||

|

XYZ axis guide rail form

|

-

|

#55

|

|

|

||

|

XYZ axis fast moving speed

|

m/min

|

12/12/10

|

|

|

||

|

Cutting feed rate

|

mm/min

|

6000

|

5000

|

6000

|

||

|

ATC form

|

-

|

Carousel / Chain

|

|

|

||

|

Tool magazine capacity

|

mm

|

24/40

|

|

|

||

|

XYZ positioning accuracy

|

mm

|

0.02/0.02/0.015

|

|

|

||

|

XYZ Repeat positioning accuracy

|

mm

|

0.15/0.015/0.01

|

|

|

||

|

Machine Weight

|

T

|

18/21

|

20/24/28

|

24/28/32

|

||

Gantry Machining Center Applications:

Metalworking:

GMC gantry machining centers can be used for cutting, milling, drilling, grinding, engraving, and other metalworking operations. These machines are highly useful in manufacturing components, tools, molds, and other metal products, improving production efficiency and precision.

Aerospace Industry:

In the aerospace sector, GMC gantry machining centers are used for processing aircraft components, engine parts, and other critical aerospace components. They are capable of achieving high precision and efficiency in metalworking to ensure aircraft performance and safety.

Automotive Manufacturing:

In the automotive manufacturing industry, these machines are used for producing automotive parts, body structures, and other vehicle components. They can handle various metal materials to meet the precision and quality requirements of automotive manufacturing.

UnionTech Machinery Co., Ltd.

is a comprehensive technology enterprise specializing in the development, manufacturing, sales, and service of CNC machine tools. The company has a professional technical team dedicated to the field of CNC machine tool manufacturing, which has set a new banner in the CNC machine tool industry with over ten years of technical experience. There are currently five mainstream product series:

vertical machining center series

,

horizontal machining center series

,

CNC lathe

, and

gantry machining center series

. The high-speed machining center machine in the vertical machining center series is our company's re promoted product. This series of machine tools has the characteristics of high speed, high rigidity, high performance, and high efficiency, and has quickly become the preferred machine tool equipment for industries such as communication, consumer electronics, automotive, and aerospace companies.

UnionTech Machinery Co., Ltd.

is based and means on precision machining, precision testing, and precision assembly, persistently pursuing high-end technology, highend market, and high-efficiency goals, closely following the forefront of industry technology, high standards, high starting points, and strict requirements.

1. Your products look similar, but the prices are different. What's the difference?

-The appearance are similar, but the models, parameters and configurations are different, so the prices are different. The better configuration, the higher prices. If you want to get an exact quotation, please contact customer service.

2. Can your offer customized service?

-Yes, we can. Please provide the specification for the machine you need, and tell us your requirements.

3.With so many machine tools, how to choose one that suits me?

-Please provide the requirements of the products you need to process: drawings, dimensions, size of workpeices etc.

we will recommend the suitable model for you according to the products you need to process.

4

. Is your machine tool 3-axis, 4-axis or 5-axis?

-We have 3-5 axis machine tools, we need to know the size you need for 4th/ 5th rotary table, NC controller ,motor brand and models, so that we can offer the quotation to you.

Hot Searches