- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380-480V Or Customized

-

Power:

-

Min 4KW

-

Dimension(L*W*H):

-

Depending on Sand Mixer Models

-

Weight:

-

Depending on Sand Mixer Models

-

Certification:

-

ISO / CE

-

Machine Material:

-

Iron Steel

-

Color:

-

Blue / Green / Yellow

-

Mixing Capacity:

-

1.5-8 t/h

-

Model:

-

S11 Series

-

Mixing Material:

-

Green Sand with iron , Mg, Water

-

PLC:

-

Siemens, Omron or famous brand in china

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

Sand Mixer, Rotor Type Green Sand Mixer Casting Machine

-

Brand Name:

-

Hezhi

-

Voltage:

-

380-480V Or Customized

-

Power:

-

Min 4KW

-

Dimension(L*W*H):

-

Depending on Sand Mixer Models

-

Weight:

-

Depending on Sand Mixer Models

-

Certification:

-

ISO / CE

-

Machine Material:

-

Iron Steel

-

Color:

-

Blue / Green / Yellow

-

Mixing Capacity:

-

1.5-8 t/h

-

Model:

-

S11 Series

-

Mixing Material:

-

Green Sand with iron , Mg, Water

-

PLC:

-

Siemens, Omron or famous brand in china

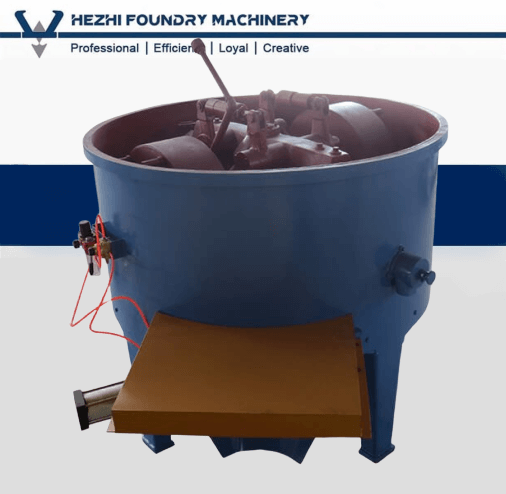

wheel rolling type foundry sand mixer adopts grinding wheel spring pressure technology. Inside and outside scrapers rolled up sand by stirring it and rotating grinding wheel.

Also known as sand roller mill; materials between roller wheel and roller table get grinded and abraded by the relative movement; at the same time, materials get mixed in the sand mixer.

S11 green sand mixer muller is economic sand mixing machine for green sand. Two wheels crush and mix foundry sands, clay, coal power and

water.

Foundry Green Sand Mixer Machine is mainly used for large and medium-sized foundry sand mixed system, mold can be mixed dry sand,since the hard sand, sand and core sand surface can also be used for glass, ceramics , refractories and other industries a variety of mixed powder granular materials.

|

Item/Model

|

S1110

|

S1120

|

S1140

|

S1180

|

S1120

|

|

Sand mixing capacity

|

1.5-2ton/h

|

2-4ton/h

|

10-13ton/h

|

13-15ton/h

|

6-8ton/h

|

|

Dis diameter

|

φ1,000mm

|

φ1,250mm

|

φ1,820mm

|

φ1,800mm

|

φ1,500mm

|

|

Main motor power

|

4kw

|

4kw

|

15kw

|

22kw

|

11kw

|

We manufacture and design full scope of green sand casting equipment. including Green Sand Mixer, Sand Feeder and Conveyor, Sand Moulding machine and Sand Reclamation Machine.

We also design custom production line of green sand casting prodcution.

We also design custom production line of green sand casting prodcution.

Finished Double roller green sand mixer in Hezhi Workshop:

Under Production Green Sand Mixer :

Single Roller Green Sand Mixer S13

The green sand mixing machine has scrapers and two high-speed rotors with a blade were installed in the machine's chassis. chassis rotates as clockwise, rotor and scraper rotate as counterclockwise. Rotor speed is higher than the speed of the chassis. Because chassis and rotor has an opposite movement, and the speed is different, so the sand of the chassis obtains different speed difference. Sand grains produce corresponding friction force and shear force, which causes the grinding, mixing, broken. This kind of machine not only mix with high efficiency, and the sand after mixing is good quality.

Quality Control System In Hezhi Machinery Group:

1. The equipment raw materials (steel) and all accessories are strictly selected. Our suppliers are long-term cooperative and reputable companies to ensure that the materials meet domestic and international standards.

2.Professional engineers with15 years rich experience provide professional & accurate detailed drawings and recommendations that meet customer all requirements, proficient in various technical parameters of the equipment,also will provide professional help &solution for customers use and maintenance.

3. The workshop employees have many years of work experience in production and manufacturing, and the company also will regularly train to ensure that production strictly follows all requirements of the process, drawings and contracts.

4. Workshop equipment is regularly maintained and optimized, and the company is still planning new workshops and introducing moreadvanced new production equipment

5. The quality inspection department will conduct strict quality inspection on all raw materials, accessories and all products produced to ensure the good quality of each equipment. Eliminate worries for customers

6. The client manager have many years of export experience, can better serve customers from various countries, and will also participate in the inspection of equipment and work with the quality inspection department to ensure product quality.manager will updating the production process to clients by sending pictures and videos every week.

7. Perfect after-sales service to solve customers' worries.

1. The equipment raw materials (steel) and all accessories are strictly selected. Our suppliers are long-term cooperative and reputable companies to ensure that the materials meet domestic and international standards.

2.Professional engineers with15 years rich experience provide professional & accurate detailed drawings and recommendations that meet customer all requirements, proficient in various technical parameters of the equipment,also will provide professional help &solution for customers use and maintenance.

3. The workshop employees have many years of work experience in production and manufacturing, and the company also will regularly train to ensure that production strictly follows all requirements of the process, drawings and contracts.

4. Workshop equipment is regularly maintained and optimized, and the company is still planning new workshops and introducing moreadvanced new production equipment

5. The quality inspection department will conduct strict quality inspection on all raw materials, accessories and all products produced to ensure the good quality of each equipment. Eliminate worries for customers

6. The client manager have many years of export experience, can better serve customers from various countries, and will also participate in the inspection of equipment and work with the quality inspection department to ensure product quality.manager will updating the production process to clients by sending pictures and videos every week.

7. Perfect after-sales service to solve customers' worries.

Qingdao Hezhi is a

manufacturer

for Foundry Machinery & Shot Blasting Machine since 2005.

Products cover Moulding Equipment,Sand Reclamation Equipment, Sand Mixer, Dust Collector and full-line Shot Blasting Machines.

Products cover Moulding Equipment,Sand Reclamation Equipment, Sand Mixer, Dust Collector and full-line Shot Blasting Machines.

We owned 3600m2 work shop area for production with 2x10 cranes.

Another 2600m2 space is planned for extension.

ISO9001 is achieved. Full set of production ,QC(3 staff) and after-sales (3 staff) guarantee none-defective products.

3D Solidworks is used in designing. R&D staff with over 20 years expertise experience meet your customized requirements.

Our philosophy: Professional, Efficienct, Loyal,

Our mission: To creat core vlaue for our customer, our staff and our company.

Choose Hezhi,Get factory price and reliable Foundry Machinery!

Another 2600m2 space is planned for extension.

ISO9001 is achieved. Full set of production ,QC(3 staff) and after-sales (3 staff) guarantee none-defective products.

3D Solidworks is used in designing. R&D staff with over 20 years expertise experience meet your customized requirements.

Our philosophy: Professional, Efficienct, Loyal,

Our mission: To creat core vlaue for our customer, our staff and our company.

Choose Hezhi,Get factory price and reliable Foundry Machinery!

FAQ ---- About Wheel type Green Sand Mixer:

Q: How long is the best sand mixing time?

A: 3-8 Min is the best time.

Q: How much to feed each time:

Q: How long is the best sand mixing time?

A: 3-8 Min is the best time.

Q: How much to feed each time:

A: Changed according to the requirement of property of molding sand if the strength of molding sand is higher, the batch capacity should be reduced.

Q: What is the order of feeding?

Q: What is the order of feeding?

A: Add molding sand prepared as needed. Add the required liquid after mixing for 2-3 minutes

Q: How many types of mixer for green sand?

A: Mainly used three types: rotor type sand mixer, double wheels type sand mixer and single wheel type sand mixer.

FAQ ---- About Hezhi Machinery:

Q: How many types of mixer for green sand?

A: Mainly used three types: rotor type sand mixer, double wheels type sand mixer and single wheel type sand mixer.

FAQ ---- About Hezhi Machinery:

A: It depends on the size of the machine. Usually 20 - 30days for shot blasting machine and sand casting machine,.45days for production line equipments.

Q: How to control your quality ?

A: First of all, we have professional technical team to design the machine. And we have strict production system, the quality inspection department will check the quality regularly.

For the smaller machine we will install the machine at our workshop to make sure it can work well.

For the bigger machine, we will install the machine for our customers until it can work well

Q: What's your machine quality guarantee?

A: Usually it's one year. We will choose the world famous brand components to keep our machine in perfect working condition.

Q: Can you instal the machine overseas?How long will it take?

A: YES, we have rich-experienced install team to instal the machine for our customers worldwide.

Q: What's your machine quality guarantee?

A: Usually it's one year. We will choose the world famous brand components to keep our machine in perfect working condition.

Q: Can you instal the machine overseas?How long will it take?

A: YES, we have rich-experienced install team to instal the machine for our customers worldwide.

More questions please contact with

Anna

, my phone No. is

0086 1995325 9235

Shot Blasting Machine

Hot Searches