- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.2-1.0mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HKY

-

Voltage:

-

380V or other

-

Dimension(L*W*H):

-

7.5m*1.6m*1.4m

-

Weight:

-

5.5 kg

-

name:

-

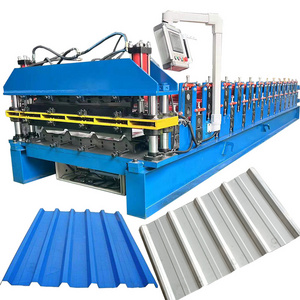

Forming Machine Roofing Sheet Metal Roll Forming Machines

-

origin:

-

China

-

material:

-

metal plate

-

control system:

-

PLC

-

sprocket:

-

P-25.4

-

roller station:

-

14

-

daimeter of pricipal axle:

-

100mm

-

material of roller:

-

45# Cr plated

-

material of blade:

-

Cr12

Quick Details

-

Type:

-

High level roof rolling machine with good service

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

8-12m/min

-

Rolling thinckness:

-

0.2-1.0mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HKY

-

Voltage:

-

380V or other

-

Dimension(L*W*H):

-

7.5m*1.6m*1.4m

-

Weight:

-

5.5 kg

-

name:

-

Forming Machine Roofing Sheet Metal Roll Forming Machines

-

origin:

-

China

-

material:

-

metal plate

-

control system:

-

PLC

-

sprocket:

-

P-25.4

-

roller station:

-

14

-

daimeter of pricipal axle:

-

100mm

-

material of roller:

-

45# Cr plated

-

material of blade:

-

Cr12

You will see the high quality of our machines from the below parameters.

1). Main Motor Power: 5.5kw/7..5kw

2). Hydraulic Station Power:4KW

3). Hydraulic Oil Pump: CB-E310

4). Sprocket: P-25.4

5). Roller Station: 14

6). Yield Strength: 32MPa

7). Material of Roller: 45#steel hard chrome plating

8). Processing Speed: 8-25m/min

9). Thickness: less than 1mm

10). Installation Dimension (L*W*H): 7.6m*1.6m*1.4m

11). Material of Blade: Cr12

12). Coil Width: 1000/1200mm/1220mm/1250mm and so on.

13). Cover Width: according to the drawing.

14). Total Weight: 5.5T

15). Equipment Parts: forming machine, hydraulic cutter hydraulic station, PLC , equipment base and linear transducer .

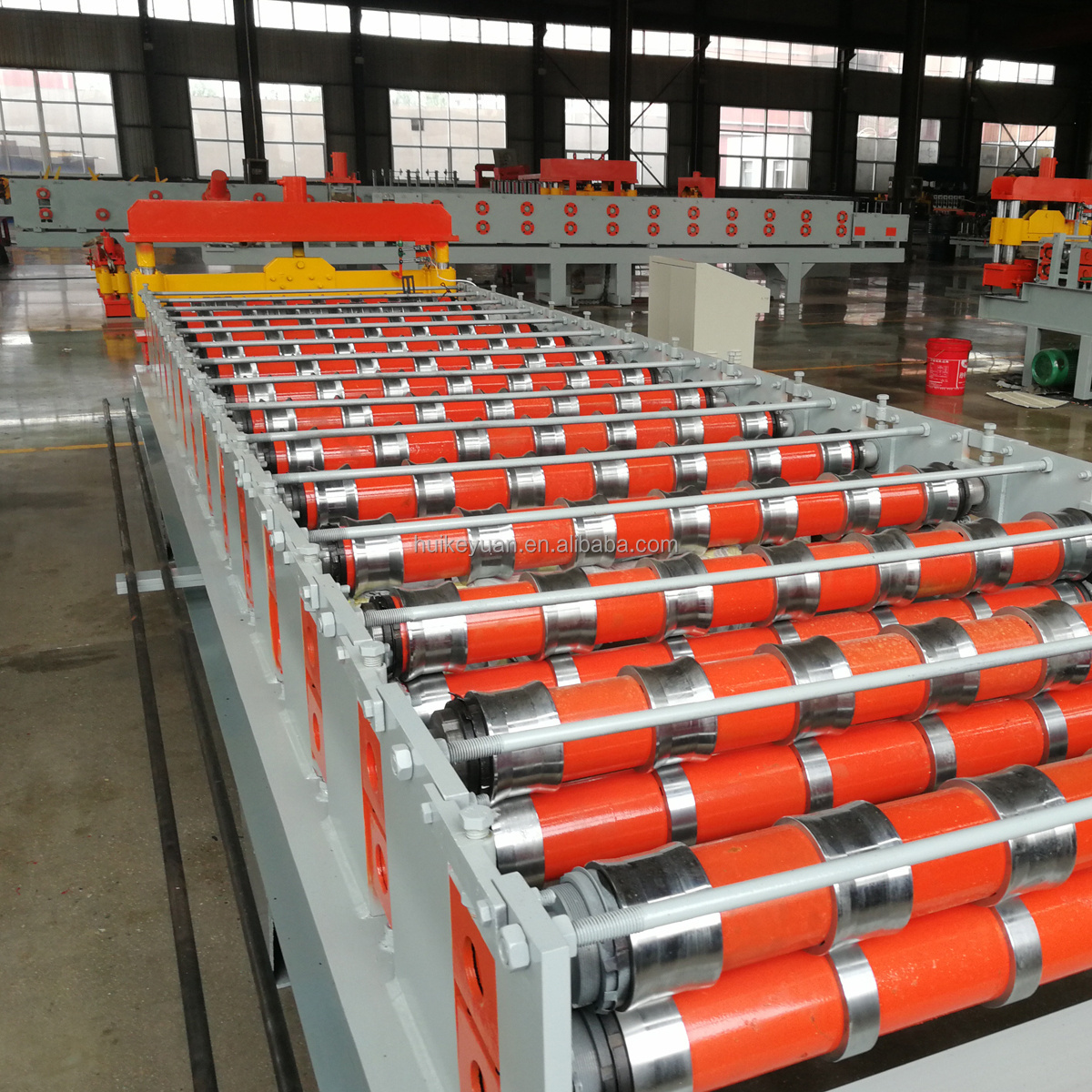

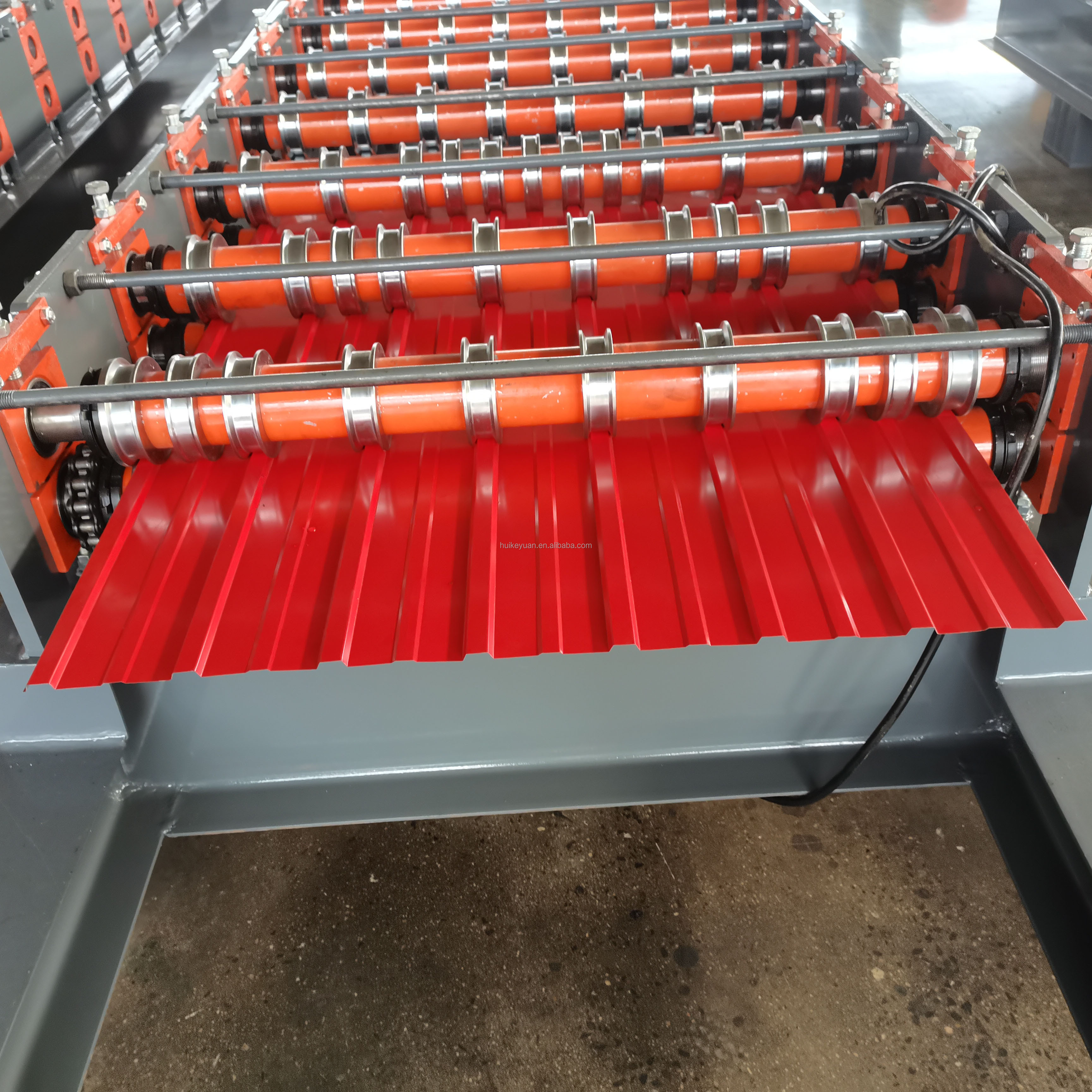

Rollers

PLC Control System.

Usually we prodvide the Delta PLC control system, but

we can make that according to your need. You need which brand, then we send to you which brand.

But the long life of that will bring you great benefit .

The Cutter.

Our company adopts this advanced technology----we call that "four poles structure hydraulic cutter", which really improve the quality of the whole machine, it cuts accurately, stable, and of course the profile edge is very nice. Recently more and more factories learn from us. But remember that, "Audi will not get the real technology from the Benz even though they said they will make that."

Every part is high quality.

From the side board to the shaft and rollers, from the feeding part to the stacker. Every part of the machine is high quality, then the whole machine is super quality.

I will send to you a form to show our machine's advantages.

Choose our machine will be your right and wise choice!

Our office building.

Our workshops

Our roll forming machine workshop

Totally we have four big workshop, roll forming machine workshop , sandwich panel line workshop , machine parts making workshop , fiber cement tile machine workshop .

Customers are visiting our factory.

We sincerely hope you can come to our company to have a visit. We will warmly welcome you.

And only after your visit, you will know which machine you should choose, which partner you should cooperate with.

Double layer glazed tile machine sent to Turkey.

Single layer machine sent to South America.

Door frame machine sent to South Africa

Sandwich panel production line sent to India

We have customers all over the world, we welcome every customer to send inquiry to us. We will provide you the machines with best price, best quality and best service.

Please chat with me for more information.

1. How many years since you have been in this field?

Our company has been producing roll forming machines for almost 20years.

We have rich experience for manufacturing and designing the machine.

2. Where is the nearest airport?

Tianjin or Beijing, both are ok. Tianjin is nearest.

From Tianjin to Cangzhou, the high speed train, it takes only 30 minutes.

From Beijing to Cangzhou, it takes only 51 minutes.

We will go to Cangzhuo railway station to pick you up, if you come to visit

our factory.

3. How about your quality and price?

Our machine uses the advanced technique, we are leading in this field.

Most of other roll forming machine factories, their boss are students of

our general manager. We always leads first in this field.

The quality is among the highest.

But the price is not high, it is low. Because our rich experience help us

to do the highest quality machine but with lowest cost. Then our price

is not high.

4. How can I contact you?

Please look at my contact method.

You can talk to me anytime.

I will reply you at the first time.

We can also make many other kinds of machines. Please sent to me email or directly chat with me or call me. I wil be very glad to be freinds with you!