- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

qiangtuo

-

Model Number:

-

GFQ

-

Voltage:

-

220V

-

Weight:

-

13000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

main motor:

-

servo motor

-

Certification:

-

CE

-

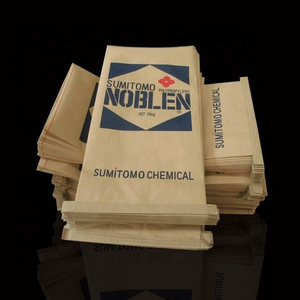

bag type:

-

paper valve pocket bag

Quick Details

-

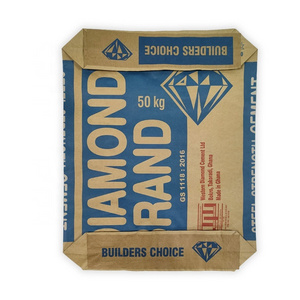

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Cement Bag

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

qiangtuo

-

Model Number:

-

GFQ

-

Voltage:

-

220V

-

Weight:

-

13000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

main motor:

-

servo motor

-

Certification:

-

CE

-

bag type:

-

paper valve pocket bag

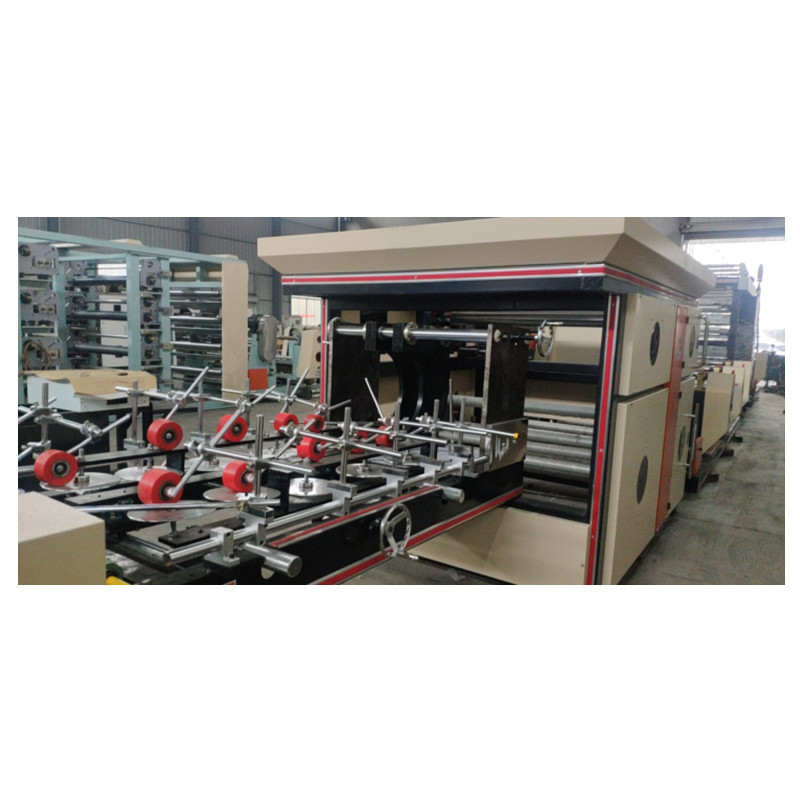

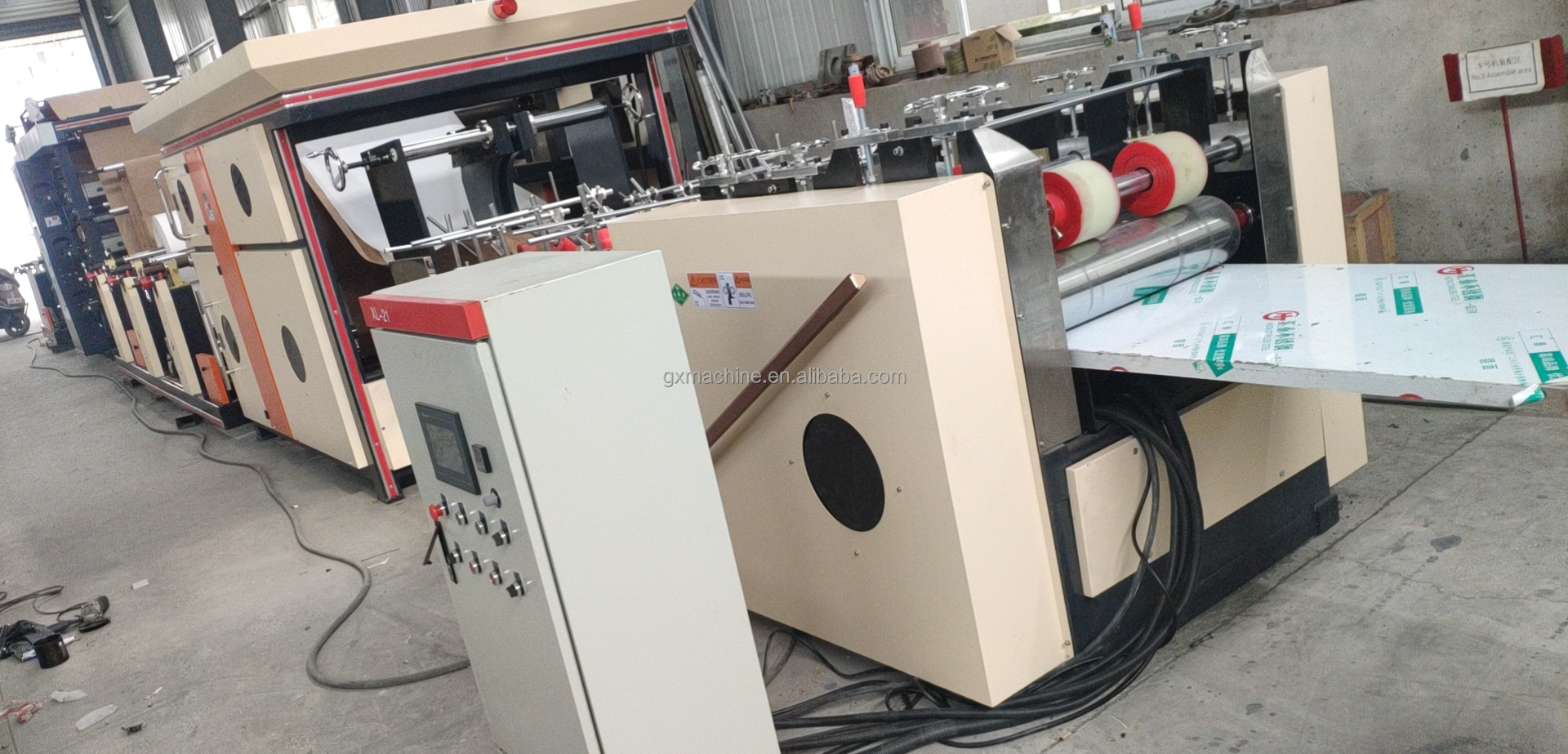

The latest design machine make kraft paper bag for cement

The tuber machine is with light, electricity, gas three-in-one high automatic production technology. It has the characteristics like human-computer interface adjustment (Touch screen control), Frequency control, Precision Servo, PLC programming control systems, Automatic counting, Alarming system for security production etc.

The main parameters

|

1).Production capacity

|

Stable speed --60-100 pcs bag plain end bag tubes / min (the production speed is determined by the bag length and the quality of paper) |

|

2).Finished bag width |

380-630mm, free adjustment (Customized in bag size range) |

|

3).Bag side |

Straight or folding side (“M” side gusset width size: 0-140mm) |

|

4).Bag length |

Free adjusted, PLC servo control the cutting length. Touch screen freely set the length |

|

5).Max layers |

4 |

|

6).Total Power |

20 KW |

|

7).Machine Dimensions |

Length13m×Width2.4 m× Height 2.1m |

|

8).Machine weight |

13 ton(around) |

|

9).Operators: |

1- 2 |

|

10) .Power supply condition |

380V,50HZ,3P ,4 L,AC |

|

11).Control method |

DELTA servo control system |

|

12).Outer layer Material |

Kraft Paper (White, brown, yellow, pink etc.) |

|

13).Inner layer Material |

Kraft Paper, PE film, Metal Foil Paper |

|

14). Kraft paper gram weight |

75-120 gsm |

|

15).Max diameter of paper reel |

1200mm |

|

16).Max paper width |

1250mm |

|

17).Paper reel inner core diameter |

76mm |

|

18). Cutting bags counting |

Automatic photoelectric counting |

The main Machine Configuration:

|

Standard configuration |

Quantity(set) |

|

Paper roll feeding rack |

4 |

|

Central glue unit |

1 |

|

Tube Shaping unit |

1 |

|

Host unit(Cutting unit) |

1 |

|

Electric cabinet |

1 |

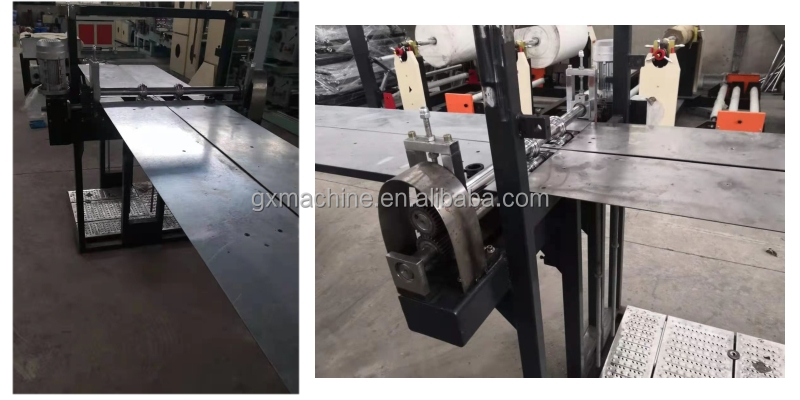

Semi-Autoamtic Pasting Auxiliary Equipment

1.Machine dimension : 4.5m*1.2m*1.4m

2.Power : around 1KW

3.Controll method : frequency control

4.Electric condition : 220V

5.Operators suggestion for assisting : 2-3 persons/set

6.Production efficiency : Determined by manually speed

7.Remark : This equipment is for assisting manually pasting

Small Valve Tube Machine

It is a micro tuber machine to make the valve tubes

1.Operator:1-2

2. Variable frequency driver

3. Frequency conversion motor: 3.5KW;

4. Intermediate relay HH52P AC200V;

5. AC contactor coil AC220V 60A ; Schneider

6. Button : Schneider ;

7. Indicator light (green); Schneider

8. Solid state relay (single phase 1.5KW);

9. Alarm lamp (sound, light);

10. Proximity switch: 2

11. Switching power supply : DC24V 2.1A

12. Equipment weight: ≈1.6t

13. Overall dimension: L 3.7m*W 1.2m*H 1.5m