- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HJ

-

Voltage:

-

220

-

Weight (T):

-

0.6 T

-

Motor Power (kw):

-

4.5 kw

-

Product name:

-

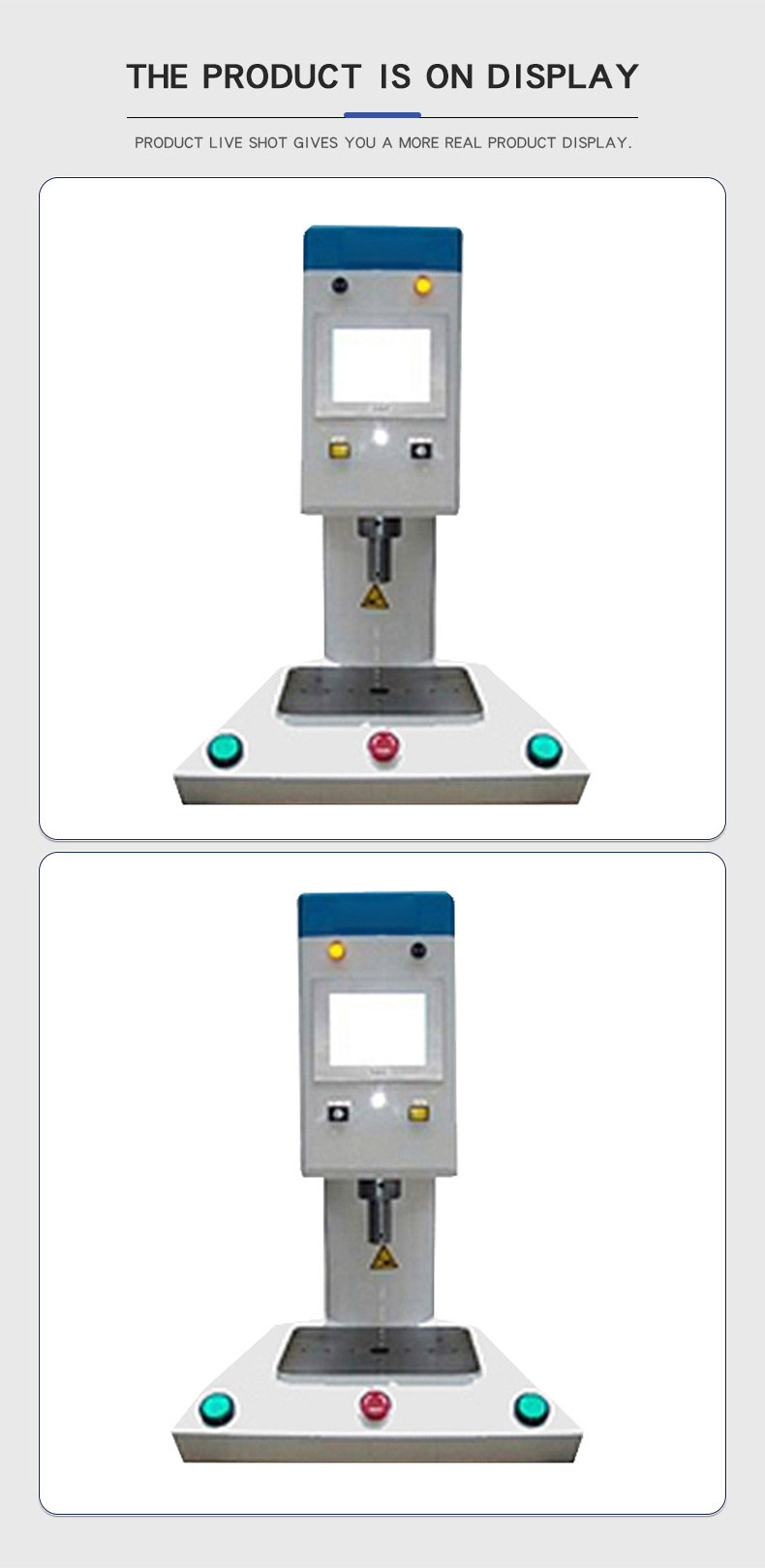

Smart Servo Press

-

Key words:

-

Smart Servo Press

-

Material:

-

Steel Material

-

Display:

-

Touch Screen

-

Usage:

-

Universal Testing Equipment

-

Power supply:

-

AC220V,50Hz

-

Weight:

-

600Kg

-

Color:

-

Customer Required

-

Size:

-

Custom Size

-

MOQ:

-

1 Pcs

Quick Details

-

Machine Type:

-

Four-column Four-beam Hydraulic Press

-

Slide Stroke (mm):

-

300

-

Return Force (kN):

-

40 kN

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HJ

-

Voltage:

-

220

-

Weight (T):

-

0.6 T

-

Motor Power (kw):

-

4.5 kw

-

Product name:

-

Smart Servo Press

-

Key words:

-

Smart Servo Press

-

Material:

-

Steel Material

-

Display:

-

Touch Screen

-

Usage:

-

Universal Testing Equipment

-

Power supply:

-

AC220V,50Hz

-

Weight:

-

600Kg

-

Color:

-

Customer Required

-

Size:

-

Custom Size

-

MOQ:

-

1 Pcs

Product Paramenters

introduce

This series of intelligent servo press is mainly used for die-cutting (full break, half break), indentation and gilding of some non-metallic materials, self-adhesive, EVA, double-sided adhesive, electronics, mobile phone rubber pad, etc. It is also suitable for all kinds of aluminum products, zinc alloy die-casting products raw edge punching and finishing.

Product features:

1, intelligent servo press is to achieve the perfect pressure and displacement of the full closed-loop control of high precision characteristics, is incomparable to other types of press;

2. Compared with traditional pneumatic and hydraulic presses, intelligent servo press can save more than 80% of energy, and is more environmentally friendly and safe, which can meet the requirements of equipment use in dust-free workshop;

3, the whole process curve of pressing force and displacement can be displayed on the LCD display touch screen, and the whole process control can automatically determine whether the product is qualified at any stage in the process of reoperation, 100% of the implementation of removing defective products, so as to achieve online quality management.

4. The pressing force, pressing depth, pressing depth and holding time of intelligent servo press can be entered on the operation panel, with friendly interface and simple operation.

5. It can customize, store and call 100 sets of press-assembly programs, and three press-assembly modes can be selected to meet your different working procedure needs.

Products Description

Hot Searches