- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380 V or other require

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

2800*1600*1580mm.

-

Weight:

-

3000 kg

-

Product name:

-

Egg Tray Forming Machine

-

Raw material:

-

Waste Cardboard Paper

-

Advantage:

-

Easy Operation

-

Capacity:

-

1000 PCS/hour

-

After-sales Service Provided:

-

Video Technical Support Online Support

-

Color:

-

Customized Color

Quick Details

-

Production Capacity:

-

60-70 pcs/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Baoyuan

-

Voltage:

-

220V/380 V or other require

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

2800*1600*1580mm.

-

Weight:

-

3000 kg

-

Product name:

-

Egg Tray Forming Machine

-

Raw material:

-

Waste Cardboard Paper

-

Advantage:

-

Easy Operation

-

Capacity:

-

1000 PCS/hour

-

After-sales Service Provided:

-

Video Technical Support Online Support

-

Color:

-

Customized Color

Products Description

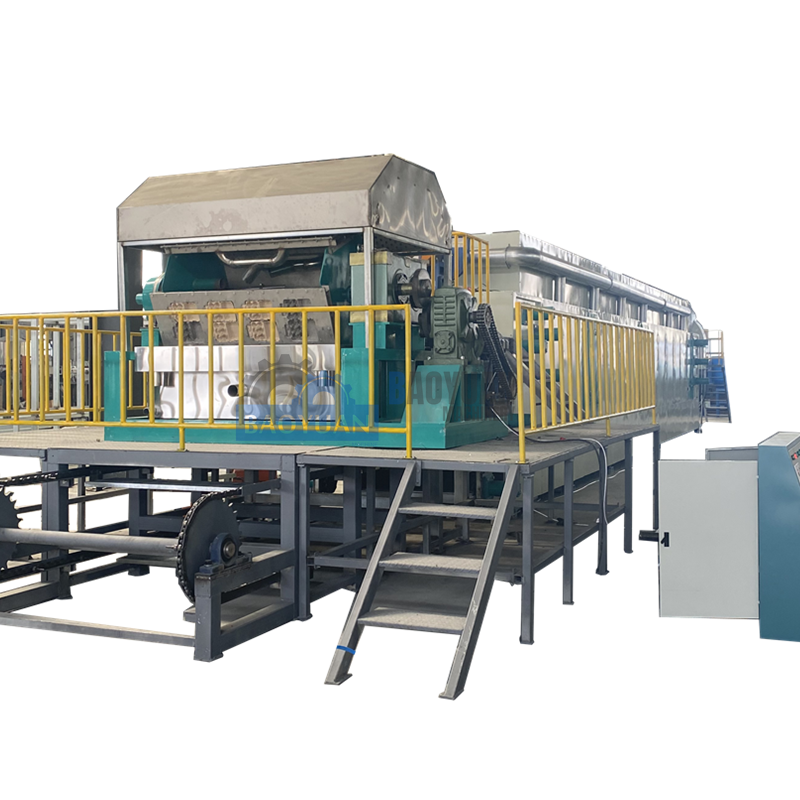

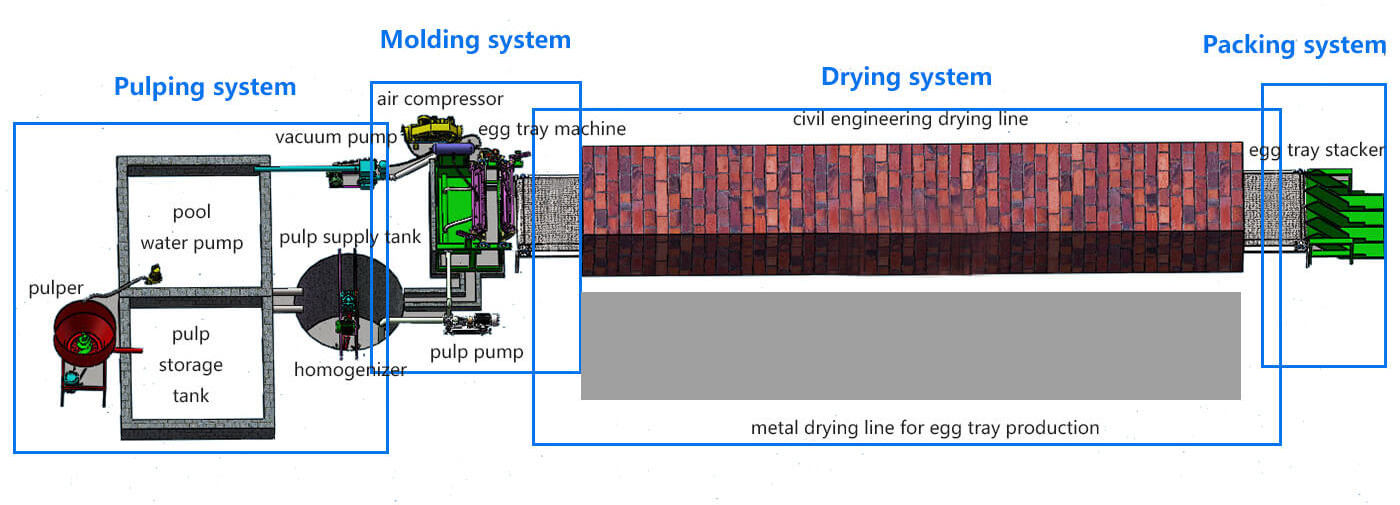

The automatic egg tray production line is composed of beating system, forming system, drying system, stacking system, vacuum system, high pressure water system and air pressure system. Specializing in the production of 10, 12, 15, 18 egg carton products. The line can produce between 800 and 6,500 egg trays per hour. It uses waste paper as raw material to make affordable and portable egg trays.

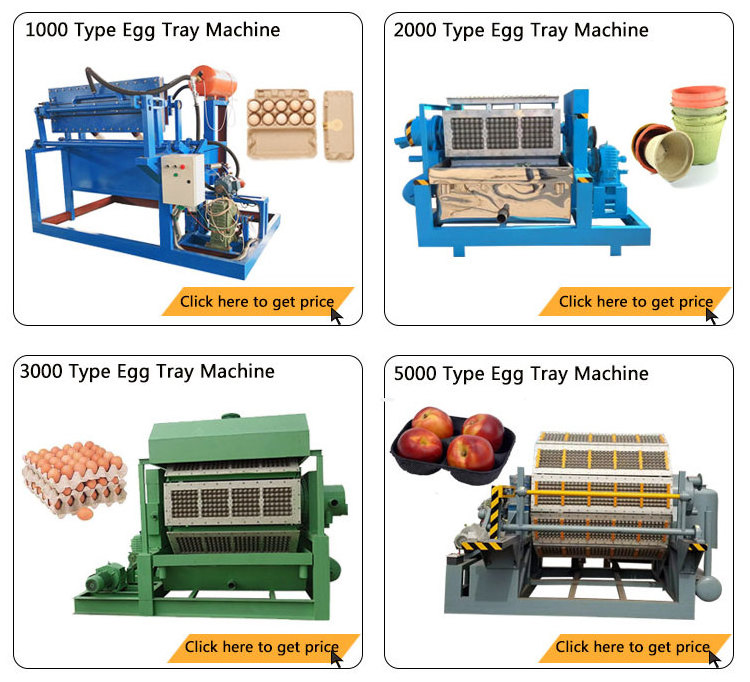

We have egg tray machines in different sizes for sale and have been successfully installed in many countries such as India, Philippines, Indonesia, Spain, Colombia, Nigeria, Botswana, Mozambique, Zambia, etc. Whether you want a stand-alone machine or a complete egg tray line.

Technical Parameters

|

Model

|

|

BY0301

|

BY0401

|

BY0403

|

BY0404

|

BY0408

|

BY0508

|

BY0608

|

|

|

Capacity (pieces/h)

|

|

800-1000

|

1200-1500

|

2000

|

2200-2500

|

3500-4500

|

5000-5500

|

6000-6500

|

|

|

Forming Mould Quantity

|

|

3

|

4

|

12

|

16

|

32

|

40

|

48

|

|

|

Total Power (kw)

|

|

33

|

42

|

53.7

|

82

|

127

|

161

|

223

|

|

|

Electricity Consumption (kw/h)

|

|

23.1

|

29.4

|

37.59

|

57.4

|

89

|

113

|

156

|

|

|

Labor Force

|

|

3-5

|

4-6

|

4-6

|

4-6

|

4-6

|

5-7

|

6-8

|

|

|

Material Consumption (kg/h)

|

Paper

|

85

|

102

|

170

|

212

|

298

|

425

|

520

|

|

|

|

Water

|

255

|

306

|

510

|

636

|

1147

|

1275

|

1560

|

|

|

Fuel Consumption

|

Coal (kg)

|

50

|

60

|

83

|

104

|

125

|

208

|

208

|

|

|

|

Natural Gas (m3)

|

22-32

|

26-36

|

37-47

|

46-56

|

56-66

|

92-103

|

92-103

|

|

|

|

Diesel (kg)

|

18-28

|

22-32

|

30-40

|

38-48

|

46-56

|

77-87

|

77-87

|

|

Our advantage

1) Simple type for producing smoothly and easy in installation and maintation.

2) Adopting advanced world famous brand components in electric parts and operation parts, quality is reliable.

3) the main character of our egg tray production line is power and energy saving, which will give you a high profit return

4) Running in a high automatization and intellectualization,no pollution, and water is recycled.

2) Adopting advanced world famous brand components in electric parts and operation parts, quality is reliable.

3) the main character of our egg tray production line is power and energy saving, which will give you a high profit return

4) Running in a high automatization and intellectualization,no pollution, and water is recycled.

Working principle and process

Step 1:

Put the prepared raw materials, such as waste paper carton,newspaper etc. Into hydrapulper, making paper pulp by the shear force and friction force of water, transfer the prepared pulp into Pulp mixing pool.

Step 2: Transfer the pulp and water into Pulp supply pool, filtering the impurities out of paper pulp at the same time,adjusting the concentration of the pulp. Now you can add such as color agent, waterproof and so on materials by your needs, stirred sufficiently.

Step 4: When the molding machine working, the water in the pulp will pumped out by the vacuum pump, then discharging the waste water into waste water pool. You can ransfer the waste water into hydra pulper and mixing pool by waster paper pump to recycled used.

Step 5: Put the wet egg tray into the dryer line for drying, and finally trim and pack the egg tray.

Step 2: Transfer the pulp and water into Pulp supply pool, filtering the impurities out of paper pulp at the same time,adjusting the concentration of the pulp. Now you can add such as color agent, waterproof and so on materials by your needs, stirred sufficiently.

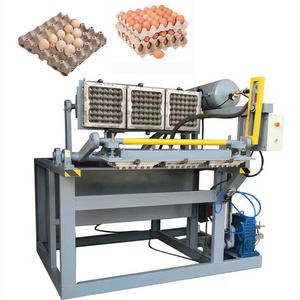

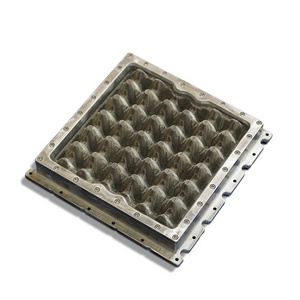

Step 3:

Pumping the prepared paper pulp from Pulp supply pool by pulp pump into egg tray molding machine, then the mold on the top sink into paper pulp completely, under the pumping action of the mold which has vacuum action in the back, pulp is adsorbed on the surface of the mold, at the same time, water in the pulp is pumped out, then the wet egg tray was formed on the surface of the mold

Step 4: When the molding machine working, the water in the pulp will pumped out by the vacuum pump, then discharging the waste water into waste water pool. You can ransfer the waste water into hydra pulper and mixing pool by waster paper pump to recycled used.

Step 5: Put the wet egg tray into the dryer line for drying, and finally trim and pack the egg tray.

Package And Shiping

Hot Searches