- Product Details

- {{item.text}}

Quick Details

-

Pipe diameter:

-

250mm-800mm

-

Center height:

-

1000mm-1400mm

-

Cooling water:

-

≤20℃, ≥0.3Mpa

-

Compressed air:

-

0.3m3/min, ≥0.5MPa

-

Humidity degree:

-

≤85%

-

Control:

-

PLC

-

Color of the machine:

-

Customized

-

Function:

-

DRAIN PIPE

-

Other name:

-

PIPE MAKING LINE

-

Certification:

-

ISO

Quick Details

-

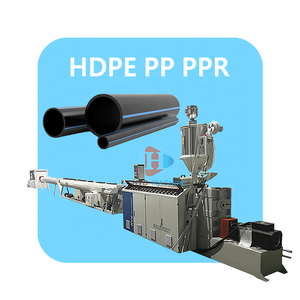

Pipe Material:

-

PE

-

Place of Origin:

-

Jiangsu, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Pipe diameter:

-

250mm-800mm

-

Center height:

-

1000mm-1400mm

-

Cooling water:

-

≤20℃, ≥0.3Mpa

-

Compressed air:

-

0.3m3/min, ≥0.5MPa

-

Humidity degree:

-

≤85%

-

Control:

-

PLC

-

Color of the machine:

-

Customized

-

Function:

-

DRAIN PIPE

-

Other name:

-

PIPE MAKING LINE

-

Certification:

-

ISO

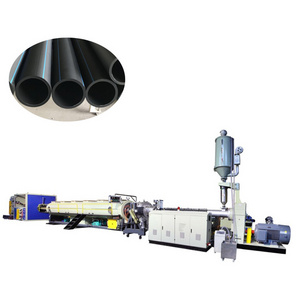

New Xingda 250-800mm PP PE HDPE pipe making line pipe production line plastic pipe making machinery

New Xingda 250-800mm PP PE HDPE pipe making line pipe production line plastic pipe making machinery

PP PE pipe extrusion machine

Process flow

Raw material + additive → mixing → vacuum feeder → hopper dryer → single screw extruder → marking line extruder → mould and calibrator → vacuum calibration tank → cooling tank → haul off machine → printer → cutting machine → pipe storage shelve

Main technical parameter

| Model | PP PE-16/63 | PP PE-20/110 |

PP PE -50/160 |

PP PE -75/250 |

PP PE -110/315 |

PP PE -200/450 |

PP PE -315/630 |

PP PE -400/800 |

| Pipe diameter | 16-63mm | 20-110mm | 50-160mm | 75-250mm | 110-315mm | 200-450mm | 315-630mm | 400-800mm |

| Max output | 120kg/h | 180kg/h | 250kg/h | 280kg/h | 320kg/h | 380kg/h | 700kg/h | 750kg/h |

| Extrusion speed | 1.2-12m/min | 1.0-10m/min | 0.8-8m/min | 0.5-5m/min | 0.4-4m/min | 0.3-3m/min | 0.2-2m/min | 0.1-1 m/min |

| Extruder model | SJ-65/30 | SJ-65/33 | SJ-75/33 | SJ-75/33 | SJ-75/33 | SJ-90/33 | SJ-120/33 | SJ-120/33 |

| Installed power | 85kw | 110kw | 125kw | 180kw | 260kw | 325kw | 480kw | 600kw |

| Center height | 1000mm | 1000mm | 1000mm | 1000mm | 1100mm | 1100mm | 1200mm | 1300mm |

| Line length | 35m | 38m | 38m | 40m | 42m | 52 m | 60m | 68m |

Noting:

Please feel free to contact us for more information. Additionally, it is worth noting that, it will be more advantageous if you told the

diameter and more details of the pipes you are going to produce when sending your messages.

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the diameter of pipe(inch or mm); thickness of pipe wall(mm)?

4) What is the electrical device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.