Our main products are: plastic pipe extrusion line and plastic recycling machine.

The main products are popular in the domestic market,such as the East China market,Southwest market,Northeast market and Central China market.The products are also exported to international market,including Russia,Australia, Southeast Asia,Middle East,East Europe.Africa and other countries.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

55

-

Warranty:

-

1 Year Warranty

-

Keywords:

-

plastic pipe extruder machine

-

Raw material:

-

PE HDPE PPR PP

-

Usage:

-

water supply hdpe pe pipe extruder extrusion machinery line

-

Pipe diameter:

-

16-1600mm

-

Pipe application:

-

water supply

-

motor:

-

Siemens Motor

-

Speed:

-

1.2-25m per minute

-

Control system:

-

PLC Control

-

Inverter:

-

ABB

-

Product name:

-

plastic pipe production extrusion machine line

-

Certification:

-

CE ISO

Quick Details

-

Screw Design:

-

Single-screw

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

55

-

Warranty:

-

1 Year Warranty

-

Keywords:

-

plastic pipe extruder machine

-

Raw material:

-

PE HDPE PPR PP

-

Usage:

-

water supply hdpe pe pipe extruder extrusion machinery line

-

Pipe diameter:

-

16-1600mm

-

Pipe application:

-

water supply

-

motor:

-

Siemens Motor

-

Speed:

-

1.2-25m per minute

-

Control system:

-

PLC Control

-

Inverter:

-

ABB

-

Product name:

-

plastic pipe production extrusion machine line

-

Certification:

-

CE ISO

Zhangjiagang City Filltech Beverage Machinery Co., Ltd.

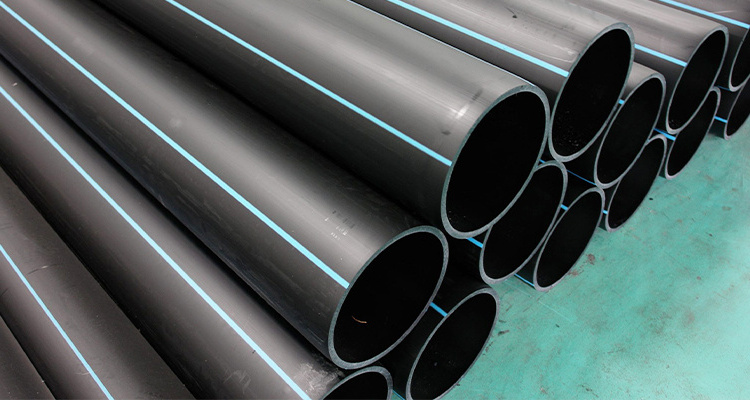

Final Products

HDPE Pipe.

HDPE is a kind of good pipeline, not only has good economy, but also has a series of advantages such as stable and reliable interface, impact resistance, anti-cracking, aging resistance, corrosion resistance, etc. Compared with traditional pipes, HDPE pipes have the following series advantage:

1. Reliable connection: the polyethylene pipe system is connected by electric heating and the strength of the joint is higher than the strength of the pipe body.

2. Good low-temperature impact resistance: The low-temperature embrittlement temperature of polyethylene is extremely low, and it can be used safely in the temperature range of -60-60℃.

3. Good chemical corrosion resistance: HDPE pipelines can withstand the corrosion of a variety of chemical media, and the chemical substances in the soil will not cause any degradation to the pipeline.

4. Anti-aging and long service life: polyethylene pipes containing 2-2.5% evenly distributed carbon black can be stored or used outdoors for 50 years without being damaged by ultraviolet radiation.

More other different type products, contact us now!

Products Description

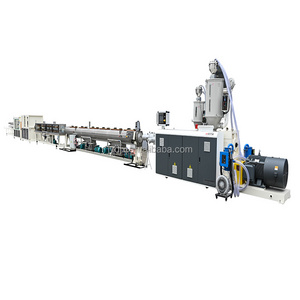

HDPE Pipe Extrusion Line.

HDPE Pipe Extrusion Machine is widely used in the whole country water supply, water sewage, gas supply and house water supply project. It includes HDPE Plastic pipe extrusion machine, LDPE Plastic pipe extrusion machines, PPR/PERT Pipe extrusion lines, ect. Filltech machinery adopts European most advance technology and develops with its own technical Strategy to ensure unique structure, high configuration, highly automation, easy operation of the whole pipe extrusion machine.

The whole line adopts PLC control system and large liquid crystal screen, which makes the operation very convenient. The line can be equipped with another extruder used for extruding the mark line.

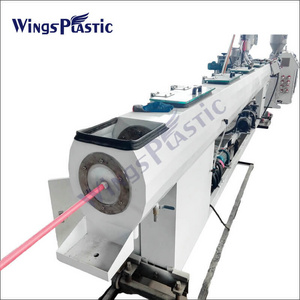

Extruder

.

High performance Extruder, which is the key important part in the whole production line, it ensure high capacity, high efficiency and excellent plasticization.

Mould.

Material: 40Cr

Design: Spiral or Basket

Single layer or Multi-layer design

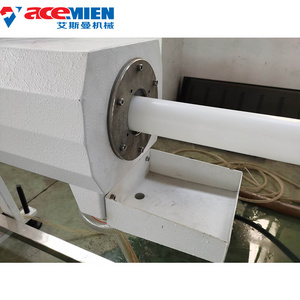

Vacuum tank

.

Material: SUS304, 5mm-7mm

Automatic water temperature and level control technology

Accurate calibration

Cooling tank.

Material: SUS304, 3mm-5mm

Fast cooling

Haul off.

Drive: by frequency inverter to servo motor driving

High quality rubber belts or blocks

With encoder for pipe metering

No-dust cutter.

Design: Universal or Cast Aluminum fixture unit

No-dust smooth cutting

Servo motor synchronization control

Stacker.

Pneumatic discharging

Automatic pipe arranging

Product Paramenters

|

Model

|

OD (mm)

|

Extruder

|

Max. Output (kg/hr)

|

Max.Haul-off speed (m/min)

|

|

HPEG63

|

Φ20-63

|

HSJ60/38

|

320

|

30

|

|

HPEG110

|

Φ20-110

|

HSJ60/38

|

380

|

25

|

|

HPEG160

|

Φ50-160

|

HSJ60/38

|

460

|

15

|

|

HPEG250

|

Φ75-250

|

HSJ75/38

|

600

|

12

|

|

HPEG315

|

Φ90-315

|

HSJ75/38

|

650

|

10

|

|

HPEG450

|

Φ110-450

|

HSJ90/38

|

800

|

8

|

|

HPEG630

|

Φ280-630

|

HSJ90/38

|

950

|

5

|

|

HPEG800

|

Φ400-800

|

HSJ120/38

|

1300

|

2.5

|

|

HPEG1200

|

Φ800-1200

|

HSJ75/38

HSJ90/38 |

1400

|

1.2

|

|

HPEG1600

|

Φ1000-1600

|

HSJ90/38

HSJ90/38 |

1600

|

0.7

|

Why Choose Us

Manufacturer.

Our machines are sold to cities in China and over the cross to Europe, American countries, Africa, Oceania, the Middle East and Asian countries. We pay great attention to our reputation, so we provide every client with good quality and service.

Factory.

We know the quality is the life of our company. Our company insists to control quality strictly by our quality inspectors. To implement this concept, we have built our own tooling and CNC workshop. Even if some parts from our certified supplier, our quality inspector will check these parts before entering into our warehouse.

Powerful.

We accept all kind of before delivery quality inspections from SGS, BV or any nominated 3rd party. In-depth understanding of customer needs, superior quality products to return the user to create maximum value for our customers. This science is a rigorous style of work and the integrity of responsible professionalism throughout the entire business of FILLTECH constitutes the core meaning of the FILLTECH brand. We sincerely hope to cooperate with you for a bright future!

Sales Manager Team and Engineer Team.

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2 / The engineers are experienced. We can produce different products with different capacities and work out reasonable flow charts as per customers' requirements to save space.

Certificates.

Verification Certificates of equipments: CE Certificate, SGS - Alibaba, SGS - Made-in-china.

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to FILLTECH site

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE FILLTECH HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

AFTER-SALE SERVICE OF FILLTECH!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

● If we can fullfill your request and you interested in our products, you may pay a visit to FILLTECH site

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE FILLTECH HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

AFTER-SALE SERVICE OF FILLTECH!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

Recommend Products

PE PP film woven bag recycling and washing line

PE PP film recycling and pelletizing line

Hot Searches