- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

1000mm*340mm*960mm

-

Weight:

-

160 kg

-

Product name:

-

Animal feed flat die feed pellet mill pelletizer machine for straw

-

Name:

-

Flat die feed pellet mill machine

-

Application:

-

Make Animal Feed

-

Pellet size:

-

1.5mm-12mm

-

Feature:

-

High Efficiency Easy Operation

-

Processing Types:

-

Poultry feed making plant

-

Feed type:

-

Pellet mill

-

After-sales:

-

Video guidance, Oversea installation

-

Usage:

-

Animal feed processing plant

-

Function:

-

Aniaml Feed Pellet Making Machine

Quick Details

-

Max. Capacity:

-

80-1500 kg per hour

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZHONGNUO

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

1000mm*340mm*960mm

-

Weight:

-

160 kg

-

Product name:

-

Animal feed flat die feed pellet mill pelletizer machine for straw

-

Name:

-

Flat die feed pellet mill machine

-

Application:

-

Make Animal Feed

-

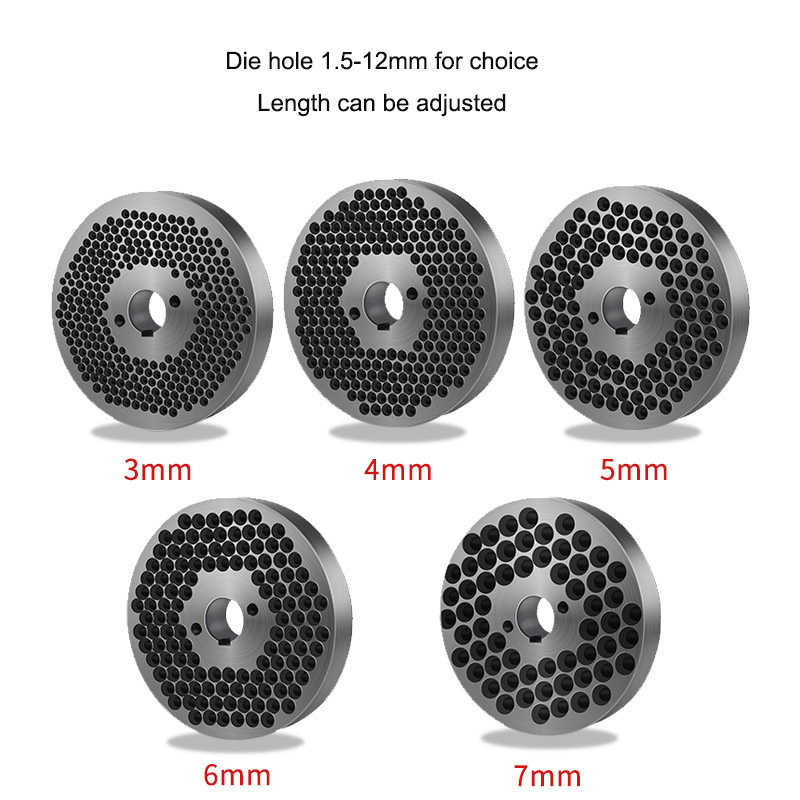

Pellet size:

-

1.5mm-12mm

-

Feature:

-

High Efficiency Easy Operation

-

Processing Types:

-

Poultry feed making plant

-

Feed type:

-

Pellet mill

-

After-sales:

-

Video guidance, Oversea installation

-

Usage:

-

Animal feed processing plant

-

Function:

-

Aniaml Feed Pellet Making Machine

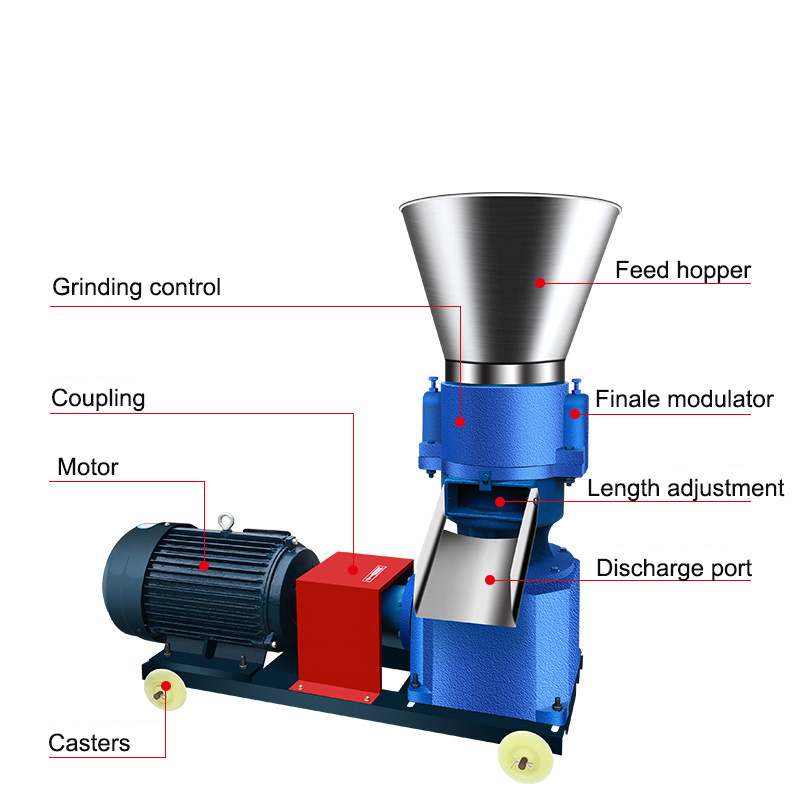

Animal feed flat die feed pellet mill pelletizer machine for straw/corn/peanut shell

Product Description

Animal feed flat die feed pellet mill machine is widely used by people who breed chicken, rabbit, cow, sheep, cattle, pig, and so on. The reason why they make feed pellets is that pellets are a balanced combination of different kinds of nutrition for the better growth of livestock, poultry and other animals.

The raw materials can be the corn, grain, soybean, peanut, wheat, straw powder, and others. Put the mixed materials into the hopper, don’t need to add the water and heating.

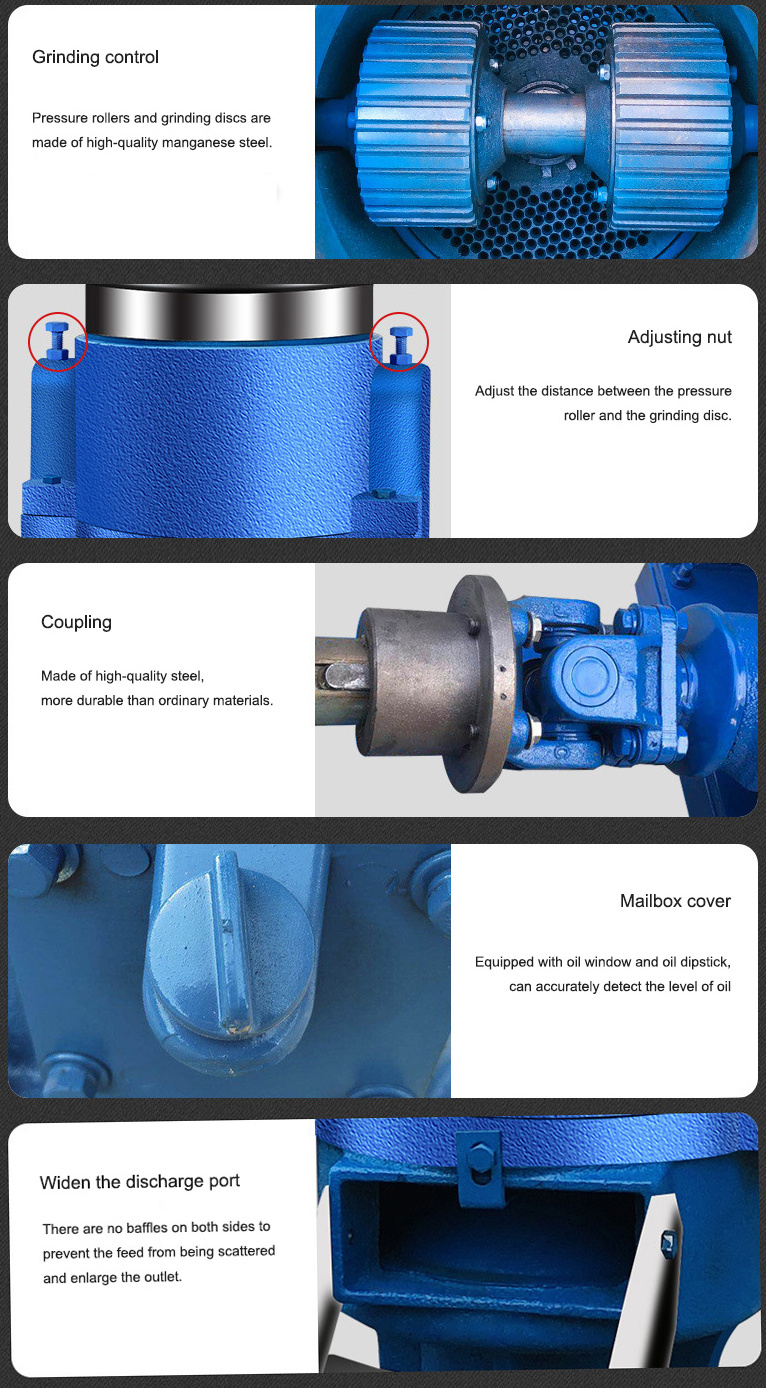

Major characteristics of Flat Die Feed Mill:

1. Simple structure, wide application, small floor space, low noise level

2. Only need to add a little amount of liquid or no need at all to make powdery feed and grass meal into granules.Thus moisture content of granule feed is basically the same moisture content before granulation, so as to be easily stored.

3. Feed of chicken, duck, fish etc guarantees higher economic benefit than mixing powdery feed.

4. Feed granules made from dry materials are with higher hardness level, smooth surface, cooked inside and will make nutrition easily digested.

5. The formation process of granules will make pancreatic enzyme boycott factor in grains and beans denaturized, to reduce bad effects on digestion and kill all kinds of parasite eggs and other pathogenic microorganisms and reduce all kinds of parasitic and digestive system diseases.

2. Only need to add a little amount of liquid or no need at all to make powdery feed and grass meal into granules.Thus moisture content of granule feed is basically the same moisture content before granulation, so as to be easily stored.

3. Feed of chicken, duck, fish etc guarantees higher economic benefit than mixing powdery feed.

4. Feed granules made from dry materials are with higher hardness level, smooth surface, cooked inside and will make nutrition easily digested.

5. The formation process of granules will make pancreatic enzyme boycott factor in grains and beans denaturized, to reduce bad effects on digestion and kill all kinds of parasite eggs and other pathogenic microorganisms and reduce all kinds of parasitic and digestive system diseases.

Specification

|

Model

|

Capacity(kg)

|

Voltage

(V)

|

Power

(kw)

|

Weight (kg)

|

Oversize(mm)

|

|

|

||

|

125

|

80-100

|

220/380

|

3

|

75

|

80

|

27

|

73

|

||

|

150

|

90-150

|

220/380

|

4

|

80

|

80

|

27

|

78

|

||

|

210

|

200-300

|

380

|

7.5

|

160

|

100

|

34

|

96

|

||

|

260

|

400-500

|

380

|

15

|

180

|

130

|

37

|

110

|

||

|

300

|

800-1000

|

380

|

22

|

260

|

112

|

46

|

125

|

||

|

400

|

1000-1500

|

380

|

30

|

380

|

170

|

62

|

155

|

||

Details Images

Our Advantages

Hot Searches