Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

XY-003

-

Brand Name:

-

xxy

-

certificate:

-

ISO9001:2015/ROSH

-

Quality control:

-

2D Projector inspection

-

Tolerance:

-

+/-0.02mm

-

Material:

-

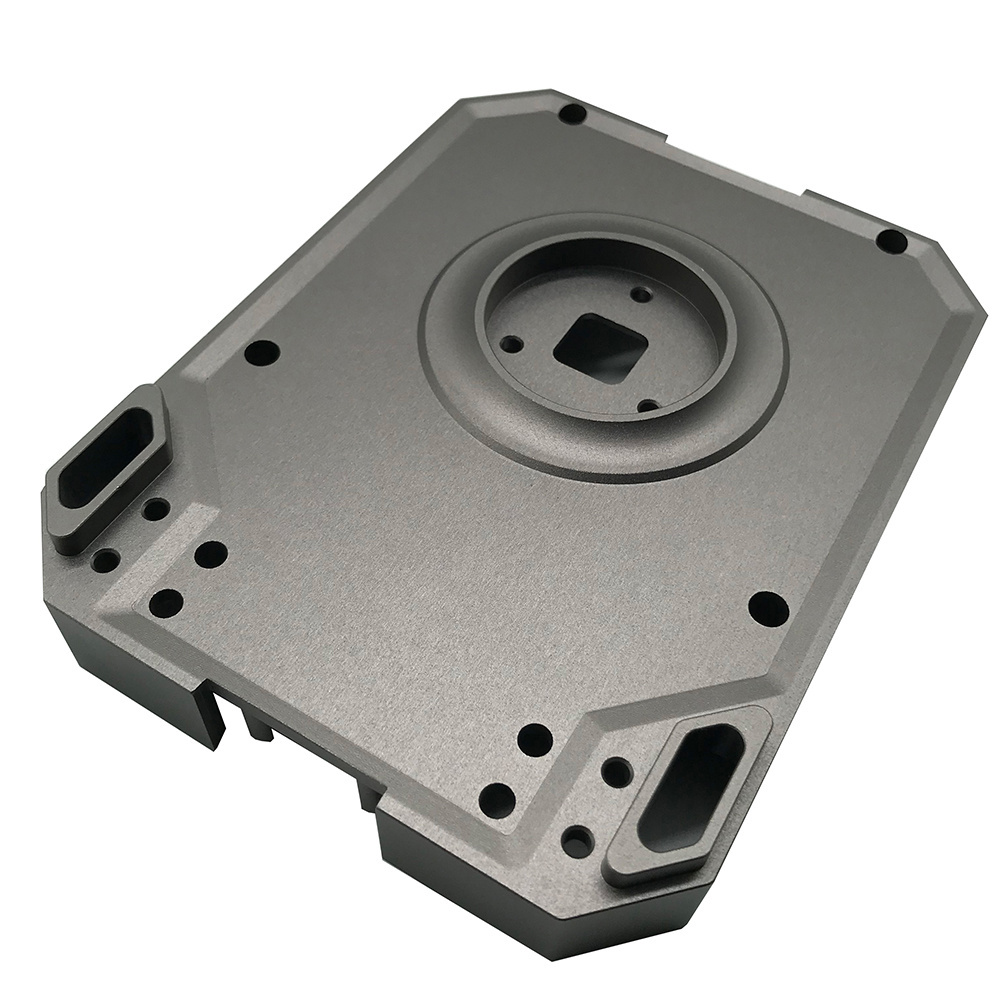

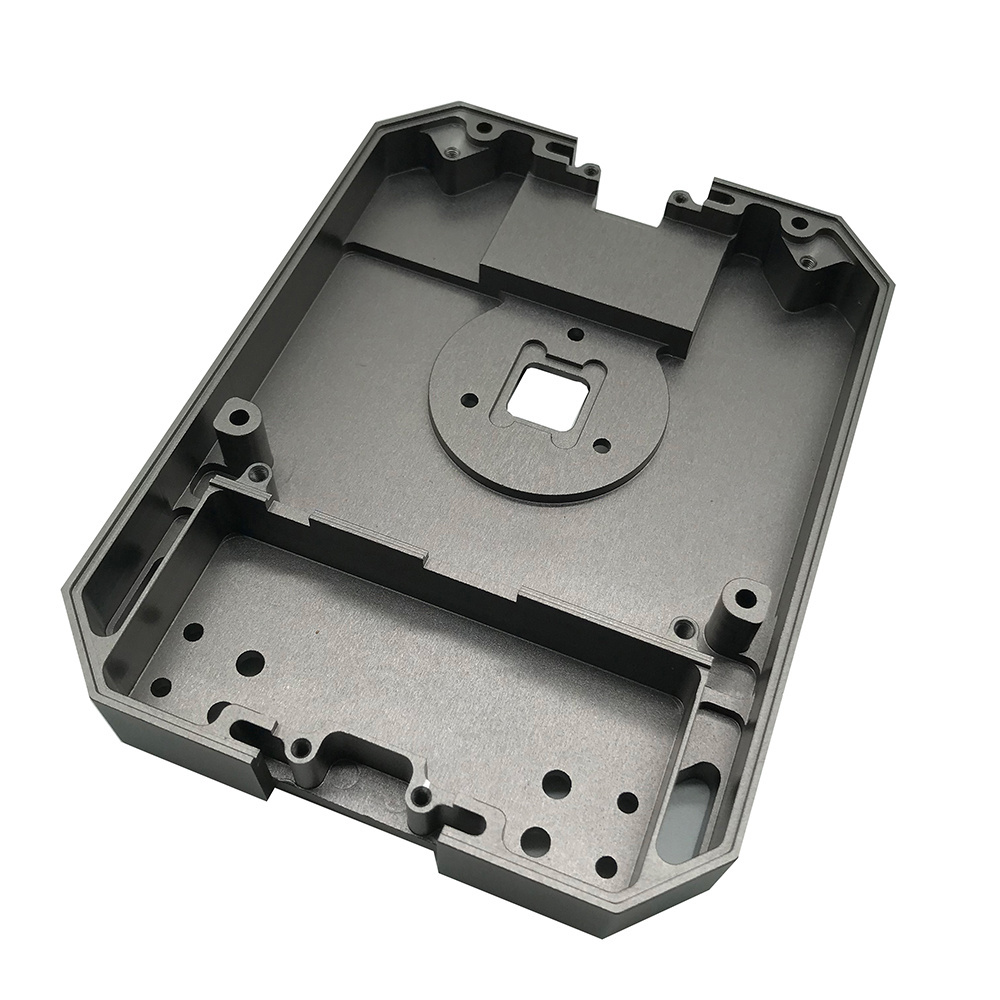

Aluminum alloy 6061

-

products name:

-

Ss Aluminum Brass Titanium Machinery Service CNC

-

Finish:

-

Powder Coating, anodizing, Plating

-

Sample time:

-

7 days

-

Service:

-

Ss Aluminum Brass Titanium Machinery Service CNC

-

Original:

-

China

-

Color:

-

all kinds of color can be made

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

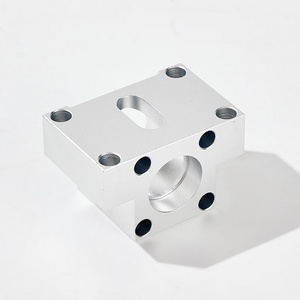

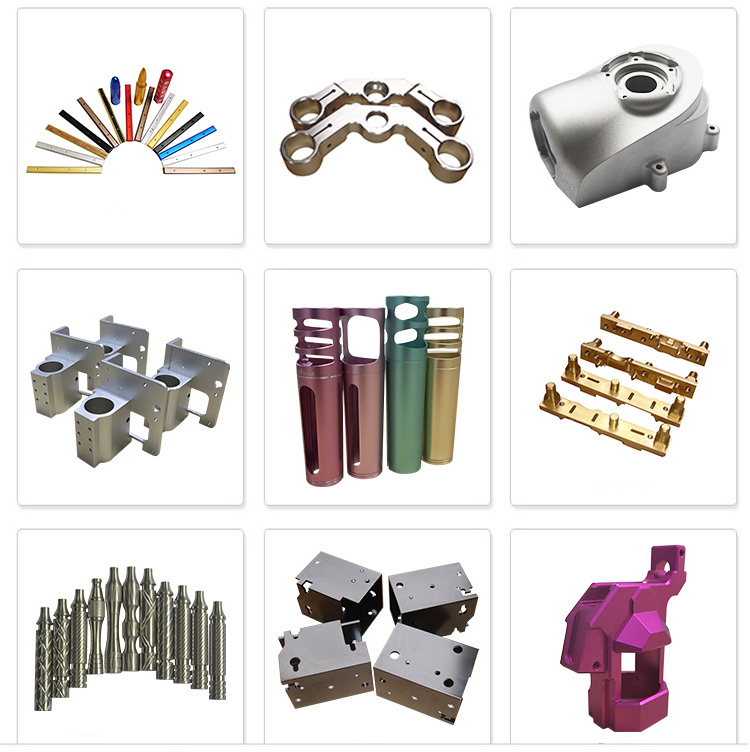

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, OEM Professional Precision CNC Turned Milled Machined Aluminium CNC Machining

-

Place of Origin:

-

China

-

Model Number:

-

XY-003

-

Brand Name:

-

xxy

-

certificate:

-

ISO9001:2015/ROSH

-

Quality control:

-

2D Projector inspection

-

Tolerance:

-

+/-0.02mm

-

Material:

-

Aluminum alloy 6061

-

products name:

-

Ss Aluminum Brass Titanium Machinery Service CNC

-

Finish:

-

Powder Coating, anodizing, Plating

-

Sample time:

-

7 days

-

Service:

-

Ss Aluminum Brass Titanium Machinery Service CNC

-

Original:

-

China

-

Color:

-

all kinds of color can be made

Machining stainless steel Parts

Shenzhen XXY Technology Co, Ltd, Passed ISO9001:2008 , your professional partner of machining parts design and manufacturing. Our market focus is to supply the professional machining solution for Industry Automation, Power Control System, Tel-communication system, Computer, Auto and hardware, Consumer electronics etc.. We are in the machining business for more than 8 years , If you have any parts need to be CNC machining or CNC Milling or CNC

Turning or Stamping or Drilling or Casting etc. , pls kindly send us your drawings or samples, we can produce the parts for you

CNC Brass Machinery Service CNC Metal Alloy Machine Spare Parts CNC Aluminum 6061 Part Services

CNC Brass Machinery Service CNC Metal Alloy Machine Spare Parts CNC Aluminum 6061 Part Services

Capabilities |

CNC center machining, Milling, drilling, turning, grinding, tapping, mould design and processing, casting, sheet mental working etc. |

Tolerances | +/-0.005mm------+/-0.02mm |

| Secondary Operations |

Bending

Brazing

|

Finishing Services |

Anodizing

Bead Blasting Hard Coat Anodizing Heat-treating Induction Heat Treating Laser Etching Pad Printing Painting Parkerizing Plating Polishing Powder Coating Precious Metal Plating |

Other Services |

Assembly

Cam Design Cam Making Design Assistance Inspection Packaging Rapid Prototyping Reverse Engineering Tool Design Tool Grinding |

Applications |

Fasteners

Housings Inserts Pinions Pins Pistons Shafts |

| Industries Served |

Aerospace

Automotive Electronics Medical Oil and Gas |

Professional Associations |

China Hardware Processing Alliance

Precision Machined Products Association

|

| Steel |

1018

Fatigueproof

|

Stainless Steel |

17-4PH

302 303 304 321 416 440 |

| Aluminum |

2011

2024 6061 6262 7075 |

Copper |

110

145

|

| Plastics |

ABS

Acetal Celcon Delron Nylon Teflon |

Inspection Equipment |

1-COVEL 14A Projector

1-MAHR Microscope w/Digital Readout 1-WILSON Rockwell Tester 4-88 pce. set of “JO” Blocks 4-COMPLETE sets of Plug Gages from 0.011” to 1” in increments of .0005” 4-COVEL 14A Projectors Indicators Micrometers Plug Thread Gages Ring Thread Gages Verniers |

Production

Equipments |

CNC Machining Center, CNC Lathe Machine, CNC Milling Machine, Drilling Machine etc. | Certificate | ISO9001:2008, SGS |

1: What are our Advantages over others?

a).We are the Manufacture,not a trading company, less cost purchase, competitive price.

b).More than 12 years' Machining Experience.

f).During our cooperation: We have QC depart.,Sales Depart.,Engineer Depart., Shipping Depart.,After-Sales,Depart.,to serve you all the time.

2: What Production Equipments do we own?

a).CNC Machines, CNC Turning Machines, Auto-Lathes, Lathes, Drilling Machines, CD Texture Machines, Screw Cutting Machines,Diamond Cut Machines, Polising Machines, Gringding Machines, etc.

3: What Inspection Equipments do we have?

a).2D Project, Height Gages, Calipers, Thickness Machines, Hardness Machines, Microcallipers, etc.

4: What is your terms of payment?

a).Usually,we accept T/T,irrevocable L/C at sight.For regular orders,we prefer 30% in advance,70% against the of B/L.For long term business relations, we have more advantage terms for payment.

5: What is your terms of delivery?

a).We accept FOB,CIF,etc. You can choose the one which is the most convenient or cost effective for you.

6: What is the lead time?

a).It usually takes 15 to 35 days after sample confirmation and receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. If the item was non standard, we have to consider extra 10-15days for tooling/mould made.

7: How about tooling Charge?

a).Tooling charge only charge once when first order, all future orders would not charge again even tooling repair or under maintance.

8: What is your sample policy?

a).Samples cost generally can be refunded if your quantity can meet our MOQ.

9: Can you produce according to the samples or drawings?

a).Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

10: How to confirm the quality with us before starting to produce?

a). QC:AQL2.5/4.0 or 100% Full Inspection. We will send you QC reports if you required