- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hydropower Station, Basement, sewage treatment plant, culvert, retaining wall, etc

-

Design Style:

-

Modern

-

Type:

-

single-side bracket

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LIANGGONG

-

Model Number:

-

Single-Side Bracket, Single-Side Bracket

-

Color:

-

Red, blue, or customized

-

Material:

-

Steel, timber beam H20

-

Height:

-

3.3 ~8.9 meters

-

Feature:

-

No through-wall tie rod,water-proof definitely

-

Fixation:

-

Anchor system, adjusting seat

-

Advantage:

-

Easy construction ,simple and quick operation

-

Certificate:

-

ISO9001

-

Packing:

-

Standard Sea-transport Packing

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, Others

-

Application:

-

Hydropower Station, Basement, sewage treatment plant, culvert, retaining wall, etc

-

Design Style:

-

Modern

-

Type:

-

single-side bracket

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LIANGGONG

-

Model Number:

-

Single-Side Bracket, Single-Side Bracket

-

Color:

-

Red, blue, or customized

-

Material:

-

Steel, timber beam H20

-

Height:

-

3.3 ~8.9 meters

-

Feature:

-

No through-wall tie rod,water-proof definitely

-

Fixation:

-

Anchor system, adjusting seat

-

Advantage:

-

Easy construction ,simple and quick operation

-

Certificate:

-

ISO9001

-

Packing:

-

Standard Sea-transport Packing

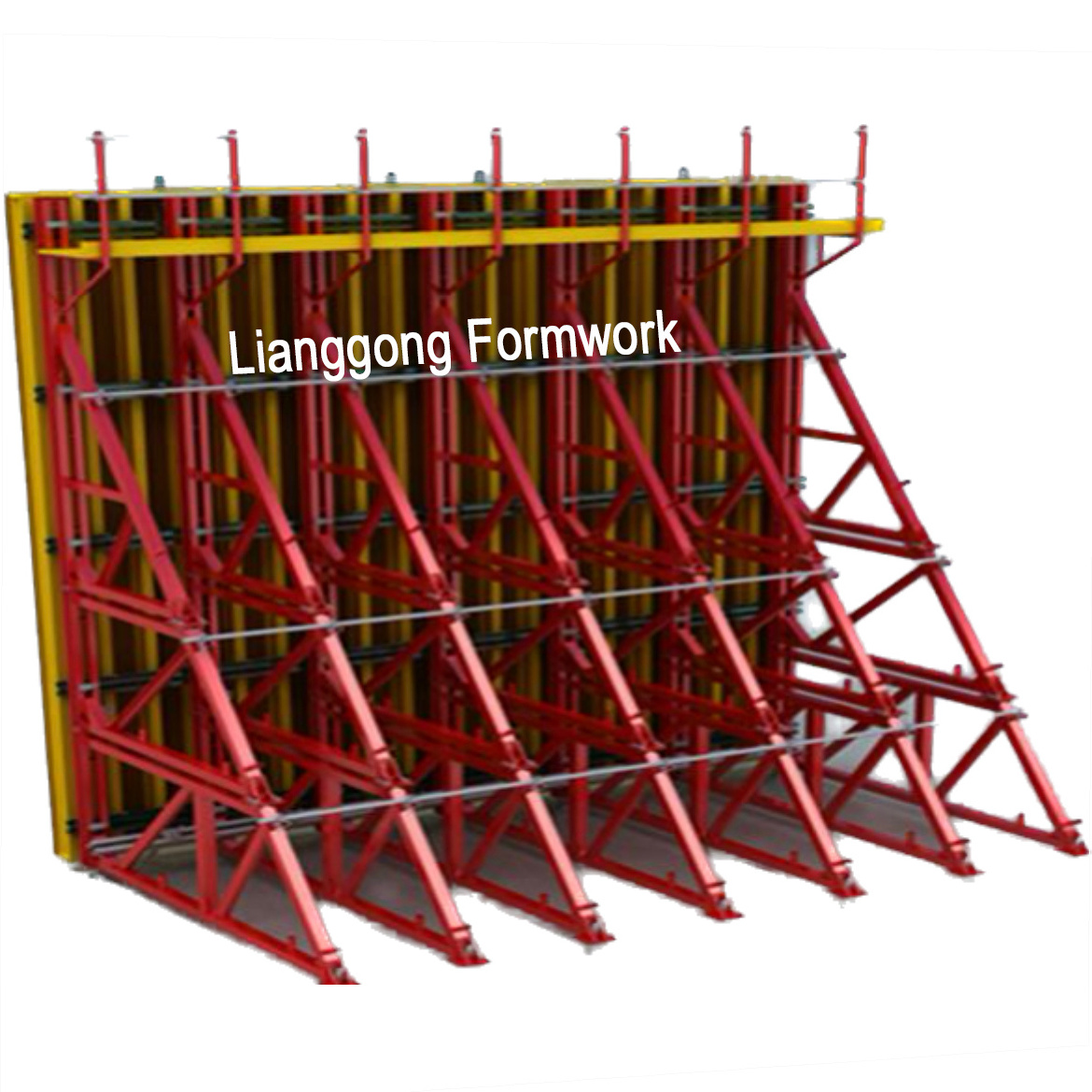

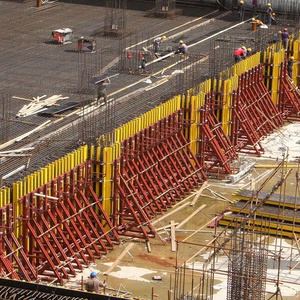

Single-side Bracket

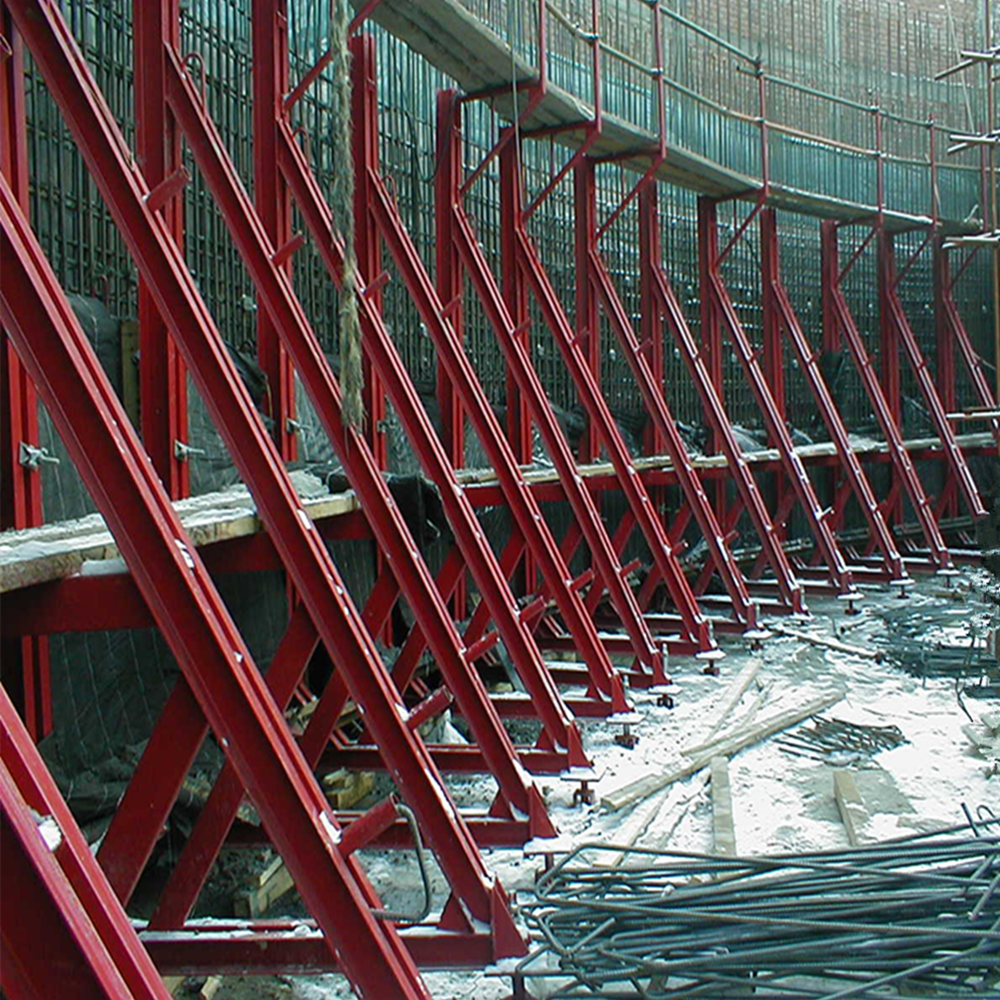

Single-sided bracket is a formwork system for concrete casting of single-sided wall, characterized by its universal components, easy construction and simple and quick operation. Since there is no wall-through tie rod, the wall body after casting is completely water-proof. It has been widely applied to the outer wall of basement, sewage treatment plant, subway and road& bridge side slope protection.

Due to the area limitation of construction sites and the development of slope protection technology, the application of single-sided bracket for basement walls is becoming more and more common. As the lateral pressure of concrete cannot be controlled without wall-through tie rods, it has caused too much inconvenience to formwork operation. Many engineering projects have adopted a variety of methods, but formwork deformation or breaking occurs now and then. The single-sided bracket manufactured by our company is specially designed to serve the need on site, and it solves the problem of formwork reinforcement. The design of the single-sided formwork is reasonable, and it has the advantages of convenient construction, simple operation, fast speed, reasonable load bearing and labor saving, etc. Maximum cast height at one time is 7.5m , and it includes such important parts as single-sided bracket, formwork and anchor system.

1.Characteristics

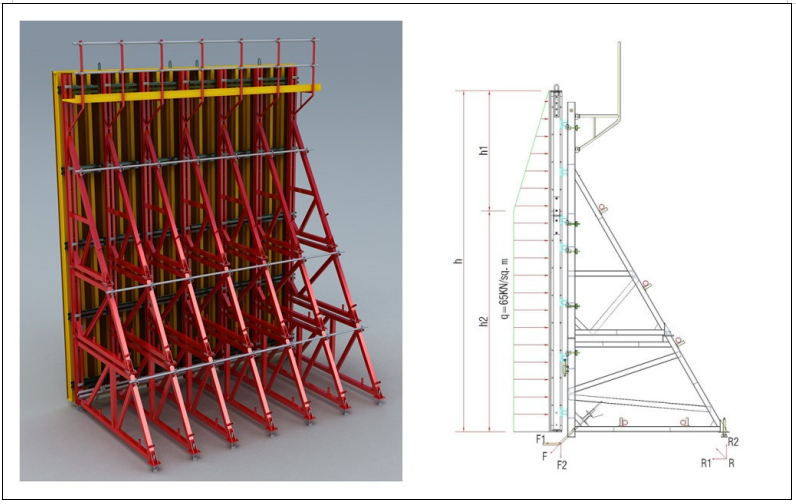

●For concrete heights up to 8.9m and a fresh concrete pressure up to a maximum of 60KN/m2.

●Good standard performance and versatility. 2.

●Fast element coupling, all units can be quickly connected.

●The finished wall is excellent and absolutely waterproof.

●Optimized sizes for transportation.

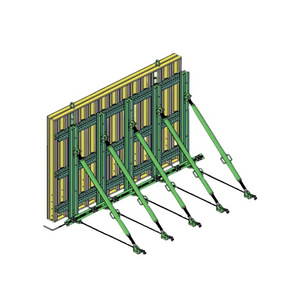

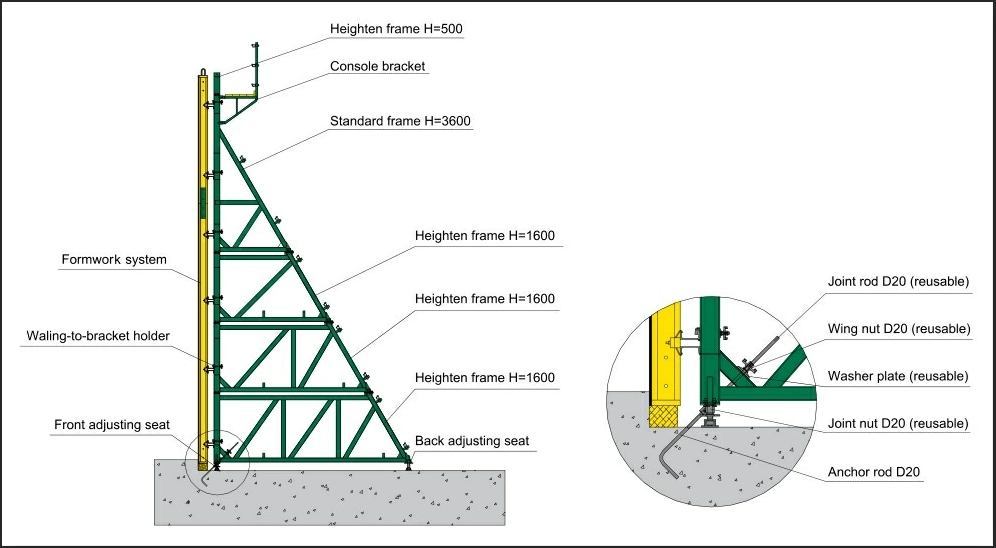

2.Structure Sketch

3.Design Principle

There is no wall-through tie-rod in the single-side bracket system. The whole system is adjusted by the anchor system and the regulator system.

The stress situation from the sketch above can not only bear the gravity force of the bracket, but also the side pressure of the concrete. This stress system is simple, reasonable and also with convenience and high safety.

4.Application

Packing Details: Packing strip, package box, steel pallet, or according to client's request

Delivery Details: Generally it is 25-30 days, it is according to quantity

Port:

Shanghai

|

1.Consulting, Design and Quotation

|

|

Offer you a general idea of formwork & scaffold among LiangGong various systems, to fit your project demand.

Design and Customized forming & shoring proposal according to your structural drawing by Auto-CAD |

|

2.Manufacture and Quality Inspection

|

|

Large-scale production workshop and First-class production line, as well as a professional quality inspection team, which will provide you with high quality standard products.

Test report will be available according to different norms from different regions in order to offer no worries to clients or meet destination authority requirements. |

|

3.Packing and Shipment

|

|

From fabrication to loading, use standard export packages to get to your site quickly.

|

|

4.Remote or On-site Instruction

|

|

If you have any questions, we can provide remote or on-site guidance. Our aim is to make customers feel at ease and satisfied throughout the process.

|

Jiangsu Lianggong Formwork Co., Ltd.

Jiangsu Lianggong Formwork Co. Ltd. is one of the leading formwork and scaffolding companies headquartered in Nanjing City, China, with its factories located in Jianhu Economic Development Zone of Yancheng City, Jiangsu Province. As a well-established company in construction formwork field, Lianggong has been devoted itself and specialized in formwork and scaffolding research, development, manufacturing, and labor service.

During the years of hardworking since 2010 by the whole company staff, Lianggong has successfully delivered and served a large number of projects at home and abroad, such as bridges, tunnels, power stations, and industrial & civil constructions. Major products of Lianggong include H20 timber beam, wall and column formwork, single-sided bracket, crane-lifted climbing formwork, hydraulic auto-climbing system, protection screen and unloading platform, shaft beam, table formwork, ring-lock scaffolding and stair tower, cantilever forming traveller and hydraulic tunnel lining trolley, etc.

Utilizing its strong technical background and abundant engineering experience, and always bearing in mind to keep its cost-effectiveness and efficiency for clients, Lianggong will continue to be your best partner in any project from the very start and achieve higher and further goals together

.

Q: Are you trading compan y or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 25-35 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples? Is it free or extra?

A:

Yes, we could offer the

sample for

free charge but do not pay the cost of freight.

Q: What is your terms of payment?

A: Payment≤1000USD, 100% in advance. Payment≥1000USD, 30% T/T in advance, balance before shipment.