- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

FYI

-

Dimension(L*W*H):

-

1,300*800*1,750mm

-

Weight:

-

500 KG

-

Power:

-

1900W

-

Product name:

-

Color Gilling Machine

-

After-sales Service:

-

Engineers available to service overseas

-

Power supply:

-

220V 50Hz

-

Dimentions:

-

1,300*800*1,750mm

-

Color:

-

Blue

-

Key word:

-

Laboratory color gilling machine

-

video Service:

-

Video technical support

-

Service Location:

-

Bangladesh

Quick Details

-

Marketing Type:

-

New Product 2022

-

Application:

-

Color gilling machine

-

Production Capacity:

-

95%-100%

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

FYI

-

Dimension(L*W*H):

-

1,300*800*1,750mm

-

Weight:

-

500 KG

-

Power:

-

1900W

-

Product name:

-

Color Gilling Machine

-

After-sales Service:

-

Engineers available to service overseas

-

Power supply:

-

220V 50Hz

-

Dimentions:

-

1,300*800*1,750mm

-

Color:

-

Blue

-

Key word:

-

Laboratory color gilling machine

-

video Service:

-

Video technical support

-

Service Location:

-

Bangladesh

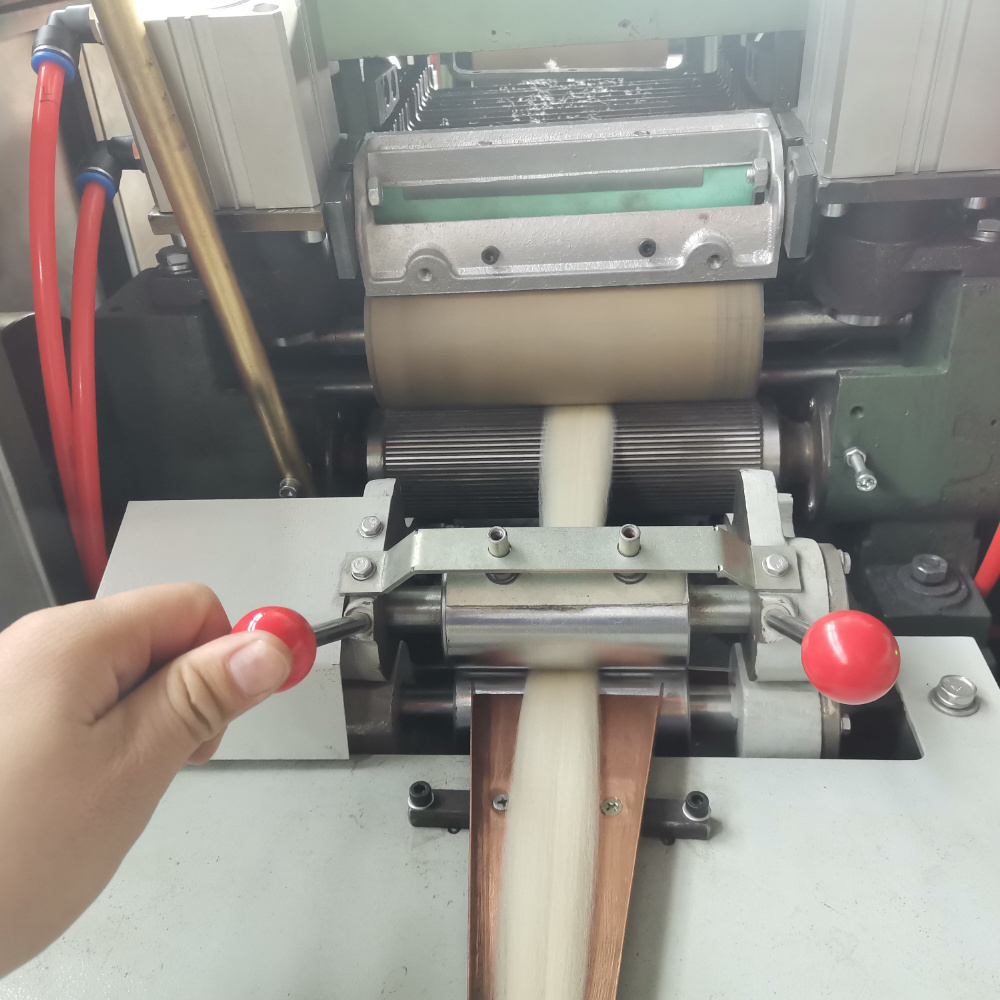

DW7021G Wool Spinning Gilling machine Gill Box Machine with Touch Screen

APPLICATION of Wool Spinning Gilling machine Gill Box Machine

DW7021G Wool Spinning Gilling machine Gill Box Machine is frequently used in the long fiber spinning system, such as worsted spinning system. The shorter fibers are further removed and the longer fibers are aligned as parallel as possible. It also helps to remove any impurities left during the carding process.

Wool Spinning Gilling machine Gill Box Machine i s one of the most important equipment in the worsted fiber processing system.

The main task of the needle-comb process is to improve the evenness of the middle and long segments of sliver by means of multi- merging and drawing . By combing the comb needle, the fiber's straightness, parallelism and separateness are further improved slightly, and hook bending and crimp are eliminated

The fiber is blended evenly and the yarn quality is stabilized by repetition, combination and drafting. Remove some of small i mpurities and short hairs .

In the long fiber spinning system, because the roller carding output sliver in the fiber parallelism and the evenness of the strip do not meet the spinning requirements, some of the “hook”bending phenomenon cannot be spun directly, especially in the worsted spinning system. If directly to the comber to receive a careful comb. It is easy to cause fiber damage in the comb as well as the rate of making. In order to increase the combing process, lab Wool Gilling Machine machine is frequently used in the former spinning process. The main effect is to improve the evenness of the sliver.

laboratory color gilling machine consists of feeding, drafting and output. The sliver is extracted from the cylinder or the wool ball is withdrawn, and arranged on the platform through the guide roller and the guide bar. The drawing part is mainly composed of front roller, rear roller (measuring roller) and comb box. There is a slow moving needle row in the carding box between the front and rear rollers, forming a longer middle control area, which can reliably control the large length and discrete fiber strips and reduce the irregular movement of short fibers. When the fibers in the draft area are controlled by the front roller to become fast fibers, the hooks are straightened and removed due to the control of the needle row and the action of adjacent fibers. The needle plate continuously penetrates the fiber layer, and with the thinning of the fiber layer, the depth of the comb needle insertion increases gradually, and the control of the fiber is strengthened continuously. The needle plate is removed from the fiber layer not far from the front roller and returned to the back roller for re-piercing the fiber layer. The reciprocating motion of the needle plate is realized by the needle plate driving mechanism.

KEY SPECIFICATION of Wool Spinning Gilling machine

|

Control mode |

PLC & Touch screen |

|

Applicable fiber length |

50~220mm |

|

Doubling |

Max. 8 |

|

D raft multiple |

3~15 |

|

Drafting type |

Single zone cross need plate draft |

|

Feeding |

Sliver (or web, please specify when order) |

|

Output |

Sliver (or web, please specify when order) |

|

Needle gauge |

7pcs/cm |

|

Number of need plate |

88pcs |

|

Max. times of beating |

800/min |

|

Max. feeding quantity |

60g/m |

|

Front roller output speed |

5~3 0m/min , adjustable |

|

Auto-stop device |

Door open auto-stop, output break auto-stop |

|

Power supply |

AC220V, 50Hz |

|

l Dimensions |

Main machine with coiler: 180*90*164cm (L*W*H) Feeding frame for sliver: length 170cm |

Good service and quantity .

A. We supply one year warranty and 12 hours service per day .

B. Our skilled engineer can go to your company for installation service

C. Our Color Gilling Machine adopts top quality material including imported parts, most of the critical component are adopting first class brand .

D. Our company passed ISO and have strict quality control before delivery goods

E. We can customized and also supply OEM service

F.. We also can supply different language user's manual . The

user manual of Laboratory Color Gilling Machine can help you operate our machine easily.

G ; we supply operation video if customer need it . .