- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5x1.1x1.7 m

-

Weight:

-

4000

-

Power (kW):

-

19

-

Model:

-

JYZ150

-

Barrel diameter:

-

150 mm

-

Total power:

-

16kw

-

Max.oil cylinder pressure:

-

36.8 Mpa

-

Max.barrel temperature:

-

95℃

-

Max. die diameter:

-

80 mm

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

dechuan

-

Voltage:

-

380,220V,415V,440V,480V

-

Dimension(L*W*H):

-

5x1.1x1.7 m

-

Weight:

-

4000

-

Power (kW):

-

19

-

Model:

-

JYZ150

-

Barrel diameter:

-

150 mm

-

Total power:

-

16kw

-

Max.oil cylinder pressure:

-

36.8 Mpa

-

Max.barrel temperature:

-

95℃

-

Max. die diameter:

-

80 mm

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE ISO

Product Description

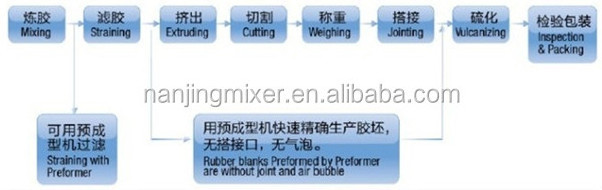

Your best choice of high quality rubber precision preformer machine in China!

Rubber Precision performer

is a high efficiency and high precision rubber blanks preparation equipment. Application in wide field of rubber industry can squeeze all kinds of middle and high hardness of rubber ring, the complex three-dimensional shape of rubber product. And the precision of rubber blank volume is high, less gas. Suitable for production of rubber parts, seals, valve, cork, tennis.

Rubber Precision pre-forming machine mainly compose of a plunger extrusion equipment and a set of rubber blanks in the machine head cutting device and, in addition with a hydraulic system, vacuum system, heating systems, pneumatic systems, and electrical systems. Pre-work precision machine, open the nose or the lid , feed the preheated rubber materials through the front barrel mount or charging inlet, and then close the head (lid), set extrusion speed and Cutting speed (supplied volume control chart), vacuum, cutting, accurate weight of rubber parts can be obtained.

Introduction of rubber precision performer:

1. Extruder device: composed of hydraulic cylinders, cylinder, head etc.

2. Hydraulic System: (Pump selection). Hydraulic machine, sealing systems and pressure pipe joints is through the repeated selection of more after being stereotyped, mostly using imported parts and the joint venture enterprise products, which fundamentally changed the previous domestic production of oil leakage phenomenon of hydraulic equipment.

3. Pressure Display: The system displays the pressure difference for advanced digital mode, the system pressure regulation and control is more precise, convenient, compared with similar products, save the addition and subtraction in phase between the two pressure gauges to method of operation to obtain the pressure difference, time-consuming and inaccurate.

4. Pneumatic device: used to control head switch (closed) cylinders and other activities.

5. Electric Control System: Siemens of Germany and Japan Fuji products, motor from ABB company, and greatly reduces the equipment failure rate of the production process, improve machine reliability, stability and service life.

6. Vacuum system: before extruding and cutting, using vacuum system to remove the air and gas in barrel, head, inside the compound mixture, thereby enhancing the quality of products under the curing process.

7. Heating System: The water cycle heating mode, temperature control by a digital thermostat and display. Ensure nose, barrel temperature constant.

8. Cutting device: composed of the frame, motor, inverter system.

9. Operating system: semi-automatic and manual operation mode of two options, allowing users to operate in the actual use of flexible and convenient situation.

10. Machine's structure, adopt the latest design ideas abroad, beautiful appearance.

Specification

|

Model

|

JYZ150

|

JYZ200

|

JYZ250

|

|

Barrel diameter

|

150 mm

|

200 mm

|

250 mm

|

|

Total power

|

16 kw

|

16 kw

|

19kw

|

|

Max.oil cylinder pressure

|

36.8 Mpa

|

20.7 Mpa

|

17 Mpa

|

|

Max.barrel temperature

|

95℃

|

95℃

|

95℃

|

|

Max. die diameter

|

80 mm

|

125 mm

|

190 mm

|

|

Rubber bland weight range

|

0.3~100 g

|

0.3~200g

|

0.3~2000g

|

|

Rubber blank weight precision(percent)

|

±1.0

|

±1.0

|

±1.0

|

|

Feed capacity per batch

|

8~10 kg

|

20~25 kg

|

60~70 kg

|

|

Blade rotation speed

|

35~300 R/M

|

35~300 r/min

|

24~300 r/min

|

|

Dimension(L×W×H)

|

4×1.1×1.7 m

|

4×1.1×1.7 m

|

5×1.1×1.7 m

|

|

Weight

|

2.8 T

|

3 T

|

4T

|

Shipment moment

Customer visit

Exhibition

Our Services

1. Reply your inquiry in 24 working hours.

2. Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

3. Professional factory: We are manufacturer, specializing in producing all kinds of machinery for more than 11 years, competitive with good quantity.

Hot Searches