Carrying capacity: 3 tons

Max coil width: 300mm

Feeding speed: 0-45 m/min (adjustable)

Driving motor power: 3 kw

Hydraulic motor power: 4kw

Structure: welding by the steel plates and profiled bar.

The decoiler is equipped with the brake system

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.46 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380v/50hz/3p (As Requested)

-

Dimension(L*W*H):

-

8.9*1.15*1.35m

-

Weight:

-

4800 kg

-

Feeding width:

-

152.4 mm

-

Marketing Type:

-

New Product

-

Advantage:

-

Easy installation and operation

-

After-sales Service:

-

Provided Lifetime technical service

-

Local service:

-

Provide Engineers door-to-door service

-

Certification:

-

CE ISO

-

Raw material:

-

PPGI,PPGL

-

Material of rollers:

-

GCr12 MOV

-

Forming stations:

-

Roller stations :15 rows

-

Diameter of shafts:

-

50mm

-

Material of shafts:

-

45# steel Tampering treatmen

-

Cutting type:

-

Hydraulic track cutting

Quick Details

-

Type:

-

drip edge roll forming machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

45 m/min

-

Rolling thinckness:

-

0.46 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380v/50hz/3p (As Requested)

-

Dimension(L*W*H):

-

8.9*1.15*1.35m

-

Weight:

-

4800 kg

-

Feeding width:

-

152.4 mm

-

Marketing Type:

-

New Product

-

Advantage:

-

Easy installation and operation

-

After-sales Service:

-

Provided Lifetime technical service

-

Local service:

-

Provide Engineers door-to-door service

-

Certification:

-

CE ISO

-

Raw material:

-

PPGI,PPGL

-

Material of rollers:

-

GCr12 MOV

-

Forming stations:

-

Roller stations :15 rows

-

Diameter of shafts:

-

50mm

-

Material of shafts:

-

45# steel Tampering treatmen

-

Cutting type:

-

Hydraulic track cutting

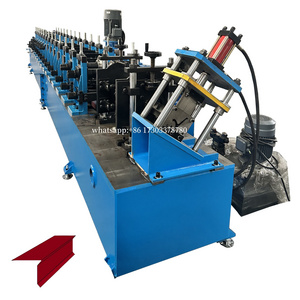

USA fully automatic Meets FBC Building Code Pre-painted Galvalume Steel 26 Gauge FHA drip edge roll forming machine

Design Idea:

High speed: 45m / min

Special Design Cutting Device:

As American customer’s requirement , the speed must fast, and to make sure it can save labor cost , so we design a stacker and packaging system.

Stable Transmission

:

gear drive.

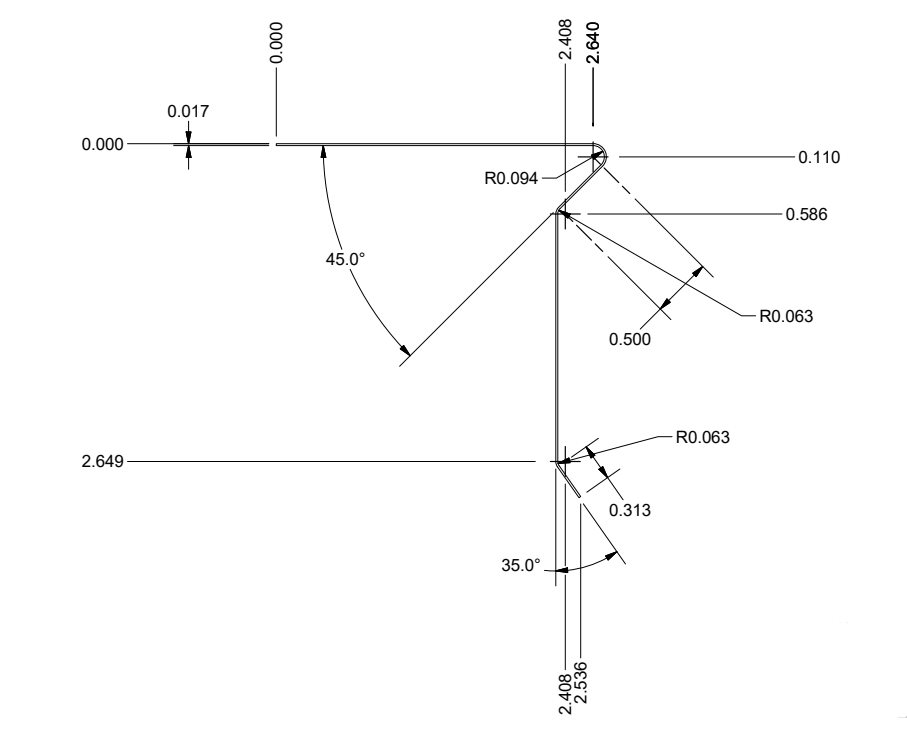

Profile drawing for reference:

Drip edge is metal flashing installed at the edges of the roof to keep water away from your fascia and from getting underneath your roofing components.

Processing Flow

Decoiler-Feeding Material-Roll Forming-Servo Cutting-Automatic stacker

|

USA fully automatic Meets FBC Building Code Pre-painted Galvalume Steel 26 Gauge FHA drip edge roll forming machine

|

|

|

|

Raw Material

|

PPGI

|

|

|

Raw material

|

Material Thickness: 0.46Mm

|

|

|

Machine Frame

|

20mm thick steel wall plate welding

|

|

|

Machine Structure

|

Vertical Arch Frame Structure

|

|

|

Material Of Rollers

|

GCr12 quenched

|

|

|

Forming stations

|

15 stations

|

|

|

Diameter of shafts

|

Φ50mm

|

|

|

Material of shafts

|

45# Steel Tampering Treatment, Prevent Deformed And Improve The Hardness

|

|

|

Forming speed

|

About 45m/min

|

|

|

Voltage

|

380v 50hz 3phase Or As local customer request

|

|

|

Transmission

|

Gear Transmission

|

|

|

|

Material Of Gear: 20 Crmnti

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Work power

|

11 kw

|

|

|

Cutting blade material

|

Cr12Mov quenched treatment to improve hardness

|

|

|

Cutting type

|

Hydraulic servo cutting

|

|

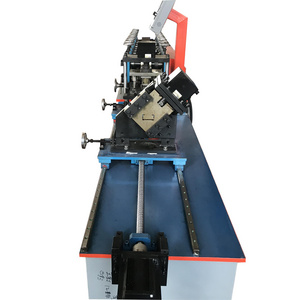

Double head 1.5T decoiler

Feeding Device

1. 2 stainless steel rollers protect raw material surface

2. With hand wheels easy adjust for feeding different thickness raw material.

3.the platform width is adjustable by hand wheel, have the bearing inside to protect the edge of the steel sheet.

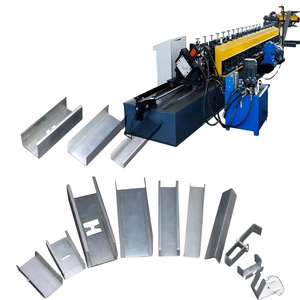

Roll Forming Device

1.

GCr12 quenched, Anti -Corrosion,Increase Hardness, Ensure The Precision And Good Abrasion Performance.

2. Each roller has number and with keynotes, it can fix on the shaft stable

Transmission Device

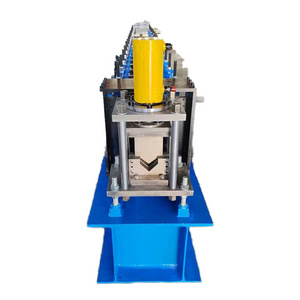

Hydraulic servo Cutting Device

1.Adopt double oil cylinder more stable than single oil cylinder 2.Hydraulic motor power 5.5 kw with energy accumulator 3.Cutter

material :GB-Cr12 with heat treatment 4.Cutting length tolerance ±10m/2mm 5.Cutting feature :Steady and safe working condition and

low sounds

material :GB-Cr12 with heat treatment 4.Cutting length tolerance ±10m/2mm 5.Cutting feature :Steady and safe working condition and

low sounds

Principle of continuous operation

We have designed an automatic oiling device on the track to prevent customers from forgetting to maintain the machine due to busy production. This way, customers can directly add lubricating oil from the oil injection port, allowing the machine to work for a long time without worrying about sliding rail damage.

PLC control system

PLC brand : Delta or Siemens

Inverter brand: Delta

Low electric part: Schneider

Encoder: OMRON

Function:

1.Adopted aviation plugs,easy installation.

Encoder: OMRON

Function:

1.Adopted aviation plugs,easy installation.

2.Full automatic easy operation. 3.Operation language:English(it can also customized language for our customer)

4.National coinsurance,spar parts Brand Siemens and Schneider.

4.National coinsurance,spar parts Brand Siemens and Schneider.

Hydraulic station

The hydraulic oil station is equipped with 2 solenoid valves and a 5.5kw high-power motor to match the high intensity operation of the machine. The hydraulic oil station needs to add 46 # hydraulic oil. When filling, there is an oil gauge display, and the filling amount exceeds the scale of the oil gauge.

Automatic Stacker

Due to the special shape of the product, we have adopted a semi-automatic stacking machine, which only requires one person to operate. It also helps customers save labor costs. And the machine is equipped with a remote control, which can be pressed to turn off the machine at any time.

CE(No.OP180719.CZIDC95)

Patent(No:ZL202021888022.3)

Hot Searches