- Product Details

- {{item.text}}

Quick Details

-

Formaldehyde Emission Standards:

-

E2

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Waying

-

Model Number:

-

Film faced plywood

-

Product name:

-

18mm marine plywood playwood price indonesian products 5x10 plywood

-

Size:

-

1220*2440, 1250*2500, 610*2440, 915*1830mm

-

Thickness:

-

9-25mm

-

Thickness tolerance:

-

+/- 0.5mm

-

Glue:

-

WBP - Melamine Glue

-

Hot pressed time:

-

2 times

-

Moisture:

-

6%-12%

-

Certification:

-

ISO, FSC

-

Advantage:

-

Good strength, factory direct, quality and reputation protection

Quick Details

-

Warranty:

-

1 Year

-

Project Solution Capability:

-

3D model design, NONE

-

Application:

-

Hotel

-

Formaldehyde Emission Standards:

-

E2

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Waying

-

Model Number:

-

Film faced plywood

-

Product name:

-

18mm marine plywood playwood price indonesian products 5x10 plywood

-

Size:

-

1220*2440, 1250*2500, 610*2440, 915*1830mm

-

Thickness:

-

9-25mm

-

Thickness tolerance:

-

+/- 0.5mm

-

Glue:

-

WBP - Melamine Glue

-

Hot pressed time:

-

2 times

-

Moisture:

-

6%-12%

-

Certification:

-

ISO, FSC

-

Advantage:

-

Good strength, factory direct, quality and reputation protection

What is film faced plywood?

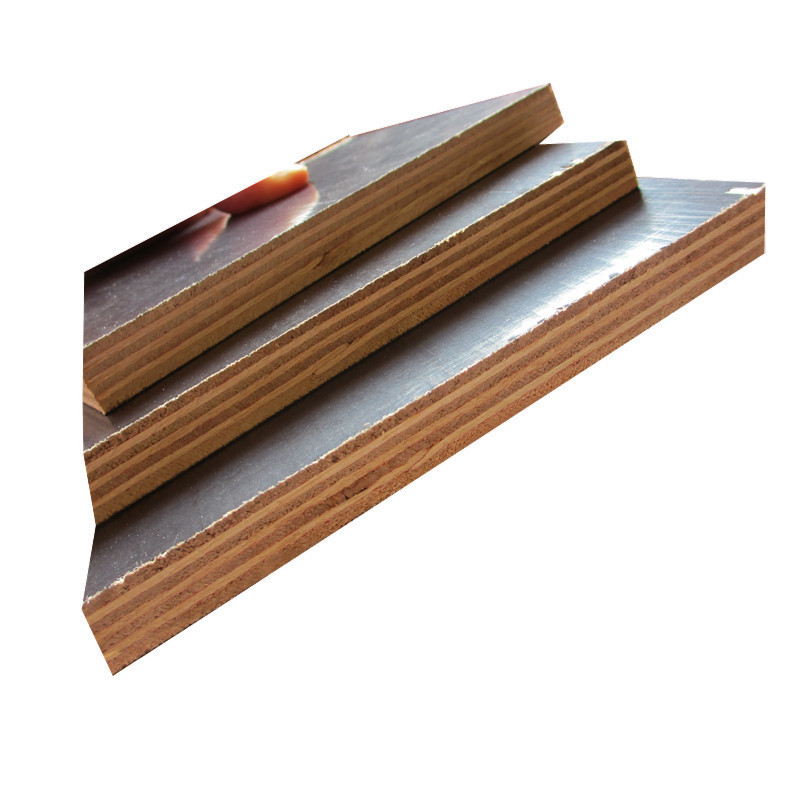

Film faced plywood is an exterior plywood used in building and construction projects. It has a special film coating on its surface made from phenol or melamine on either or both sides which gives the plywood a higher resistance to water, abrasion, chemical degradation and fungal attack compared to ordinary plywood.Covering film has bright luster, many colors can be selected.Having a smooth or mesh surface.

Because of its increased stability and resistance to moisture, ultraviolet radiation and corrosive chemicals, film-faced plywood is ideal for outdoor applications such as the external surfaces of new buildings. The extra film layer and acrylic varnished edges of this type of plywood make it more durable and less able to distort when used outdoors in harsh weather and adverse conditions.

In Africa and West Asia,they call our plywood as the marine plywood.In South Asia ,Philippines , people call our film faced plywood as the phenolic plywood, and also some clients from Europe and Canada call them the shutter formwork etc.

|

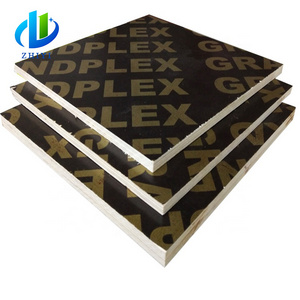

Product Type:

|

Film faced plywood,Anti-slip plywood,Marine plywood,Phenolic plywood,Shutter formwork

|

|

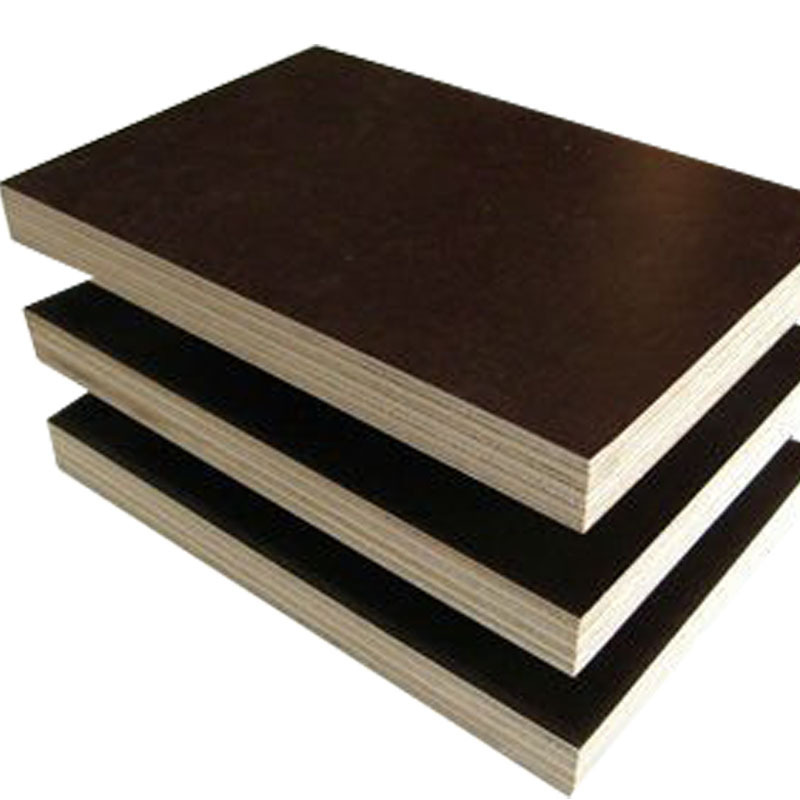

Size:

|

1220*2440mm,1250*2500mm or Customized

|

|

Thickness:

|

9mm, 12mm, 15mm, 18mm, 20mm, 21mm or Customized

|

|

Glue:

|

WBP/Melamine glue(can be boiled for 48 hours)/Phenolic E0 glue (can be boiled for 72 hours)

|

|

Film:

|

Black film, Brown film

|

|

Core:

|

Full eucalyptus wood,Full poplar wood,Full birch wood,Recycled finger joint

|

|

Packing:

|

Inner with plastic bag,then Steel tapes for strength, 3 times on width and 6 times on length, plywood sheet or Carton covering, with strong pallets.

|

|

Usage:

|

Construction,concrete forms, shuttering, formwork, stage, packaging, ect.

|

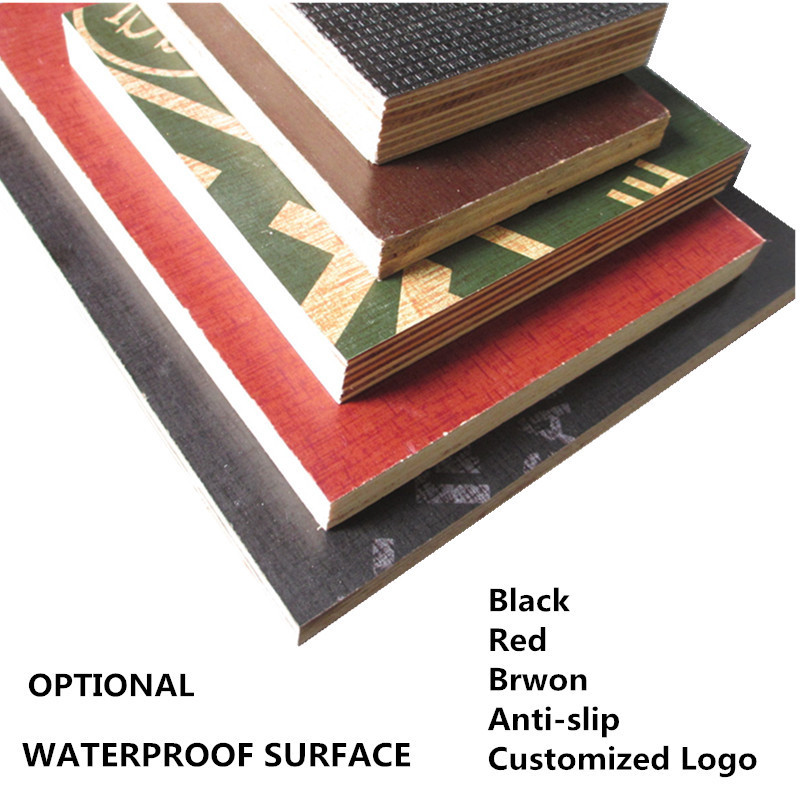

Features:

2.Tolerates the most corrosive environments, including chemicals.

3.Can prevent skidding to the maximum extent.

4.High water resistance.

6.comes in a variety of thicknesses and sizes.

7.Many colors: There are many colors to choose from.

8.The price is moderate and the price is good.

Film faced plywood production process