- Product Details

- {{item.text}}

Quick Details

-

Power:

-

13 kw

-

Weight:

-

200 KG

-

Dimension(L*W*H):

-

2500*780*1150 mm

-

Capacity:

-

100 kg/hour

-

Name:

-

Electric frying machine continuous mesh belt cassava fryer

-

Color:

-

Silver

-

Material:

-

304 Stainless Steel

-

Application:

-

Restaurant

-

Type:

-

Frying Equipment

-

Heating type:

-

electric heating

-

Suitable:

-

snack foods potato chips

-

Certification:

-

CE Certification

-

Feature:

-

Save Oil

Quick Details

-

Place of Origin:

-

Shandong, China, China

-

Brand Name:

-

Huagang

-

Voltage:

-

220V/380V

-

Power:

-

13 kw

-

Weight:

-

200 KG

-

Dimension(L*W*H):

-

2500*780*1150 mm

-

Capacity:

-

100 kg/hour

-

Name:

-

Electric frying machine continuous mesh belt cassava fryer

-

Color:

-

Silver

-

Material:

-

304 Stainless Steel

-

Application:

-

Restaurant

-

Type:

-

Frying Equipment

-

Heating type:

-

electric heating

-

Suitable:

-

snack foods potato chips

-

Certification:

-

CE Certification

-

Feature:

-

Save Oil

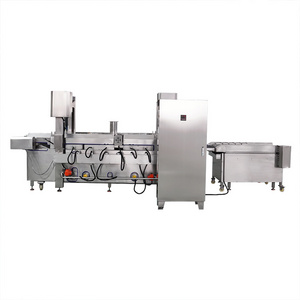

Electric frying machine continuous mesh belt cassava fryer nugget donut gas heating belt conveyor frying machine

Main structure and working principle for Electric frying machine continuous mesh belt cassava fryer nugget donut gas heating belt conveyor frying machine

1. It is composed of transmission motor, chain conveyor, oil tank, filter device and electrical parts.

2. The mesh belt conveyor adopts frequency conversion stepless speed regulation, and the frying time can be controlled.

3. The upper and lower double-layer mesh belts are used for transmission, and the product is clamped in the middle of the double-layer mesh belt to avoid product floating; The distance between the upper and lower mesh belts is adjustable.

4. The equipment mesh belt rack can be lifted out for easy cleaning.

5. Inject the specified amount of oil into the oil tank, turn on the electric heating pipe switch, and determine the oil temperature according to different fried foods. When the oil temperature reaches the specified value, start the conveyor motor and the conveyor belt starts to operate. Set the frying time according to the fried food and adjust the speed of the conveyor chain. When the oil temperature rises, evenly put the food to be fried into the input port (the input amount should preferably account for 50 ~ 60% of the total area)

Operation use for Electric frying machine continuous mesh belt cassava fryer nugget donut gas heating belt conveyor frying machine

1. Clean the oil tank and conveyor belt, remove foreign matters and dirt, and wipe dry the water.

2. Close the oil drain valve and fill the oil tank to the specified oil level. (generally, it can be flush with the plane of the net under the pressure strip)

3. Turn on the power.

4. When the oil temperature reaches 160 ℃, start the reducer to start the conveyor belt

5. Set the frying time and oil temperature. When the oil temperature rises to the required temperature (determined according to the fried food), put the fried food into the input port (the input amount should preferably account for 50 ~ 60% of the total area and put it evenly)

6 in order to effectively remove the suspended particle impurities of frying oil, inhibit the rise of acid value and prevent oxidation, so as to prolong the service life of frying oil. In order to ensure the quality of fried food, oil filter should be equipped with better effect.

u) If the machine is equipped with an oil filter, when the oil temperature is 120 ℃ ~ 170 ℃ after production, start the oil filter (see the operation manual of frying oil filter for the operation method). The filtered oil can be automatically pumped into the oil storage tank (the oil storage tank is provided by itself). After the oil in the frying oil tank is filtered, clean the oil tank, remove the slag removal device, clean the inside and outside of the sediment tank and equipment. After cleaning, put the oil in the oil tank back to the oil tank and cover the full cover plate.

Technical parameters for Electric frying machine continuous mesh belt cassava fryer nugget donut gas heating belt conveyor frying machine

| Model | YZ-2500 |

| Voltage | 220V/380V |

| Power | 13 kw |

| Width of belt | 200 mm |

| Volume of oil | 55 L |

| Dimension(L*W*H) |

2500*780*1150 mm (Customizable according to customer's requirement) |

All functions can be customized according to customer requirements and can be used to match the nugget / burger forming line

Step 1: Firstly, the product is wrapped with stretched film.

Step 2: Secondly, put the

product

in and around the iron frame.

Step 3: Thirdly, the smoke proof board is sealed around the

product

for export.

Step 4: Finally, the packaged

product

is shipped.