Explore More Products

- Product Details

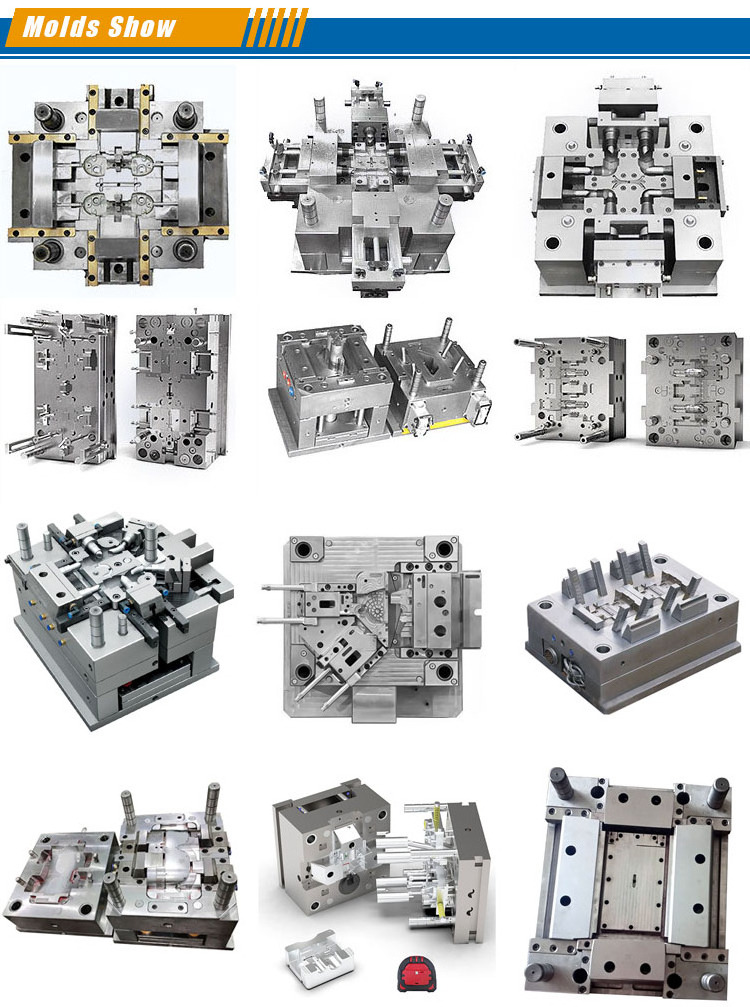

- {{item.text}}

Quick Details

-

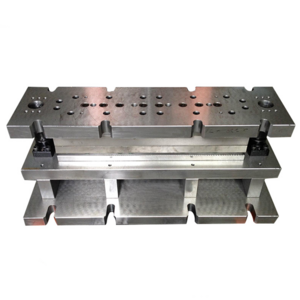

Model Number:

-

pow-054

-

Product Name:

-

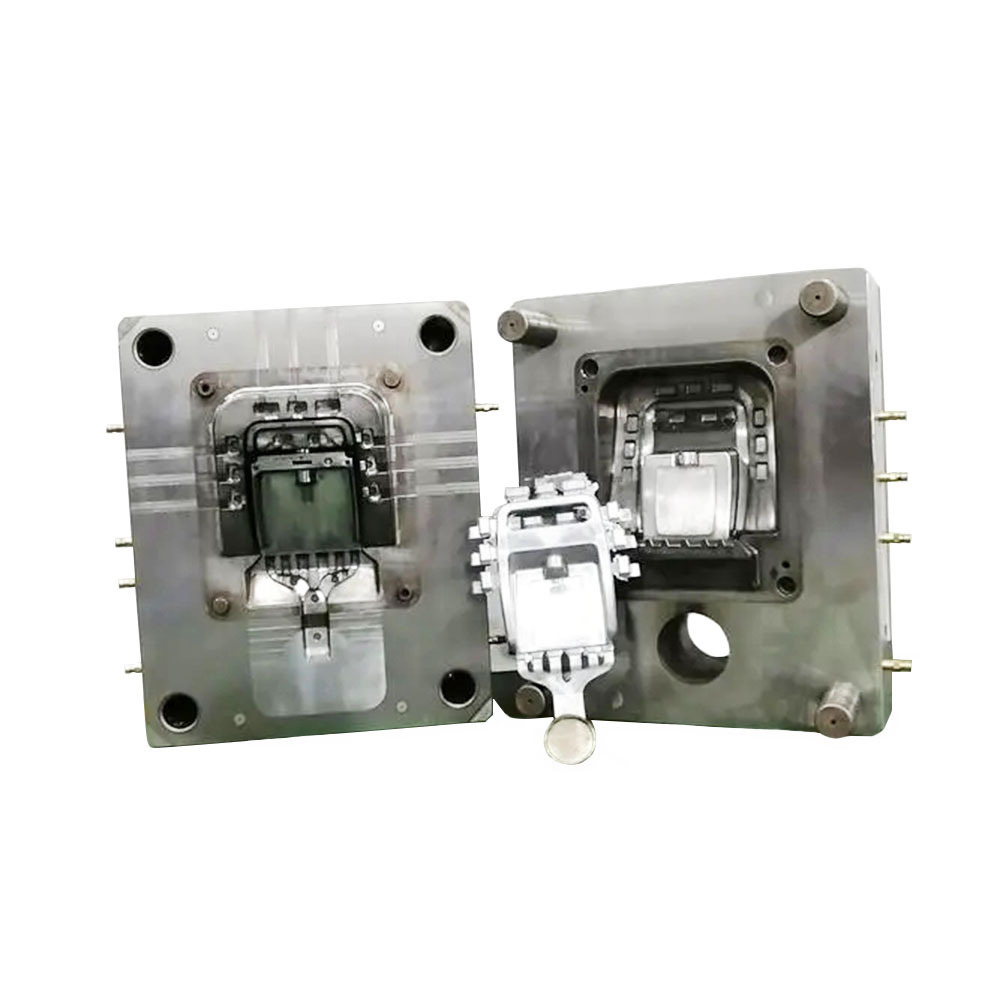

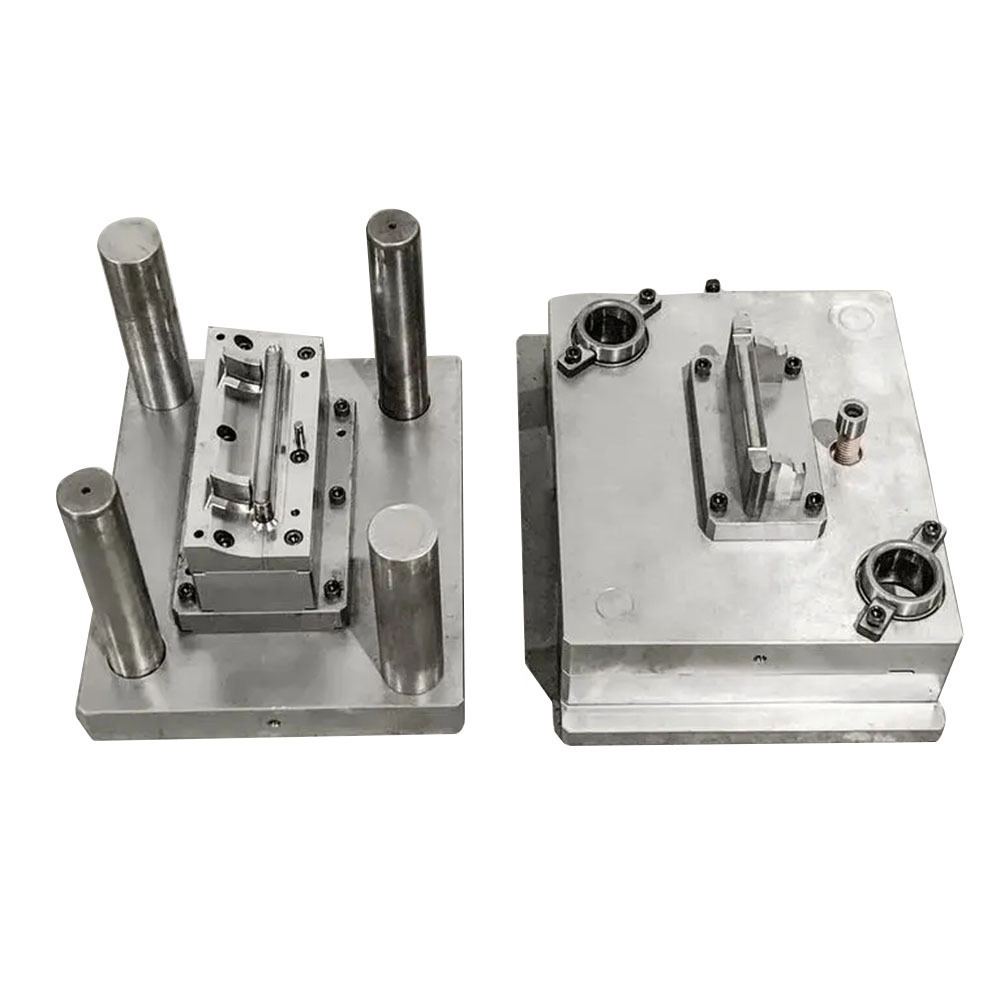

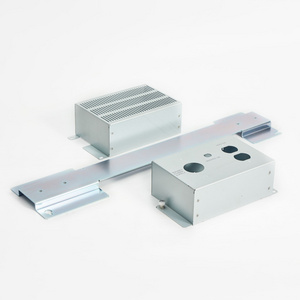

Precision Die Casting Parts

-

Material:

-

Aluminum\ Zinc alloy

-

Mould base:

-

LKM

-

Design software:

-

AutoCAD/Pro-E/solidworks

-

Mould life:

-

100000-200000 times

-

Cavity:

-

Multiple or single

-

Surface treatment:

-

According to your requirement

-

Mould material:

-

H13, 2344, 8407, 8418, SKD61, DAC, FDAC

-

Runner:

-

Hot Runner\ Cold Runner

-

Delivery Time:

-

45-50days

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Powerstar

-

Model Number:

-

pow-054

-

Product Name:

-

Precision Die Casting Parts

-

Material:

-

Aluminum\ Zinc alloy

-

Mould base:

-

LKM

-

Design software:

-

AutoCAD/Pro-E/solidworks

-

Mould life:

-

100000-200000 times

-

Cavity:

-

Multiple or single

-

Surface treatment:

-

According to your requirement

-

Mould material:

-

H13, 2344, 8407, 8418, SKD61, DAC, FDAC

-

Runner:

-

Hot Runner\ Cold Runner

-

Delivery Time:

-

45-50days

|

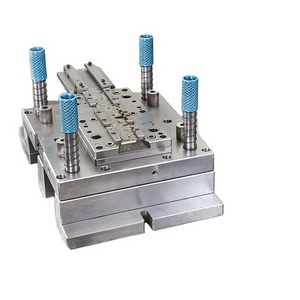

Product Name

|

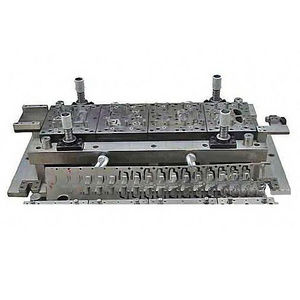

China OEM Customized die casting mould

|

|

|

||

|

Mould material

|

H13, 2344, 8407, 8418, SKD61, DAC, FDAC

|

|

|

||

|

Product Material

|

ADC12,A380,AlSi12,A356,A360,ZL102,etc.

|

|

|

||

|

Information to quote

|

2D,3D,samples or pictures of multiple points of view with dimensions.

|

|

|

||

|

Size&weight

|

As per your drawings or samples.

|

|

|

||

|

Leadtime for mould

|

Usually 4-8 weeks. It also depends on mould size and structure complexity.

|

|

|

||

|

Cavity number of mold

|

Single cavity, Multiple cavity or one mold with different products

|

|

|

||

|

Service life

|

100000-200000 times

|

|

|

||

|

Surface treatment

|

Plating Chrome or nickel,sandblasting,powder coating,painting,etc.

|

|

|

||

|

Main process

|

Milling, grinding, CNC, EDM, wire-electrode cutting, carved, electrospark, lathe, etc

|

|

|

||

|

Software

|

SolidWorks, UG,CAD(IGS,X-T,STP),PDF

|

|

|

||

|

Mold design time

|

Within 3 days(generally)

|

|

|

||

|

Mould testing

|

All of the moulds can be well tested before the shipments. Videos for testing the moulds are available according to clients' requirements.

|

|

|

||

|

Good packages

|

In strong wooden pallets to avoid any damages during the long transportation

|

|

|

||

Our services

2. Plastic Injection molding&Plastic Injection mould

3. Vacuum casting/vacuum forming(Silicon Mould)

4. Low Volume Production

5. Rapid Hardware/Sheet Metal Prototypes.

6. CNC Aluminum/Brass/Copper/Bronze CNC machining

7. Automotive and medical equipment Prototypes

8. SLA/SLS prototype

9. Metal Stamping&NCT Stamping

10. 3D Printing

11. Die-casting, hardware machining

12. Electronic Manufacturing Service

13. Lathing parts

14. Design service (OEM service)

FAQ

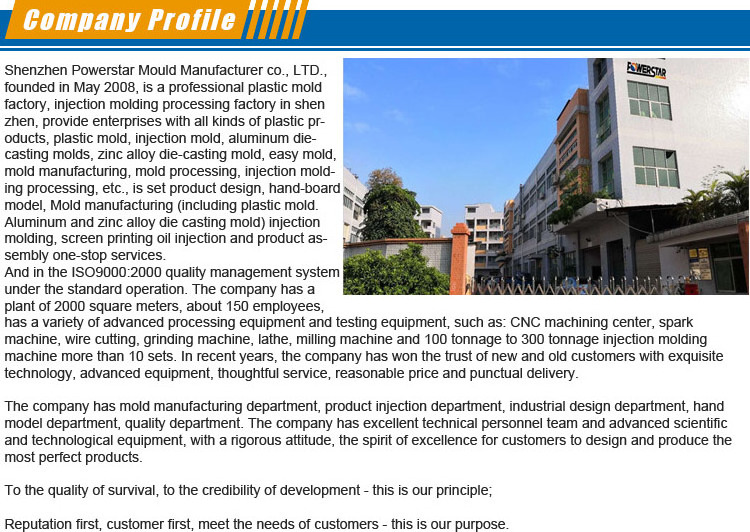

1,Q:How many moulds could you make every month?

A:60-80 sets.

2,Q:How about the largest mould you ever made?

A:15 ton. The size is 1.8m * 1.5m.

3,Q:How about the tolerance?

A:Mould tolerance 0.005mm, Product tolerance 0.01mm.

4,Q:What is percentage of automotive moulds you made? What's the brand?

A:About 40%. Brand: Volvo, TOYOTA,Land Rover.

5,Q:Can you make precision mould ?

A:Yes. We have made precision moulds such as moulds for medical devices.

6,Q:How about the steel you usually use?

A:We only use raw materials with good quality like P20, P20H, 718H, NAK80,1.2311,1.2378, 1.2344, 1.2767, H13,8407, 420SS, S136, S-7. They are all from famous suppliers, such as LKM, ASSAB, THYSSEN, etc. Steel quality certificate and heat-treatment certificate will be provided along with the tools while delivery.

7,Q:What about the standard components you use?

A:We use standard components from LKM,, HASCO, DME, etc.

8,Q:What do you need for quotation? And what about the format?

A:2D & 3D part files are preferred. Or specific sample with detailed description and mould specification. We use PROE, AUTOCAD, Acorbat Reader, Solidworks, UG and etc. All format related are acceptable.

9,Q:How long do you need for quotation?

A:Exact quotation will be available within 2 working days once we get sufficient information from customer.

10,Q:What is your turnround time for die casting mould building?

A:Usually 4-8 weeks. It also depends on mould size and structure complexity.

HOW TO CONTACT US?

Contact person:Jenny LO

Tel:86-0755-26586158

Mob:0086-15999501102(WhatsApp&Wechat)

Email:jenny at powerstar-cn.com

Web:http://www.powerstar-metal.com

Skype:loujiana