- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/600V or customized

-

Dimension(L*W*H):

-

2700*2500*3900

-

Power (kW):

-

55

-

Weight (T):

-

2.1

-

Core Components:

-

Other

-

Name:

-

Plastic grinding machine crusher

-

Product name:

-

Crusher machine

-

Crushing material:

-

Types Waste Plastic

-

Color:

-

Customized Color

-

Usage:

-

Waste Plastic Cusher

-

Size:

-

Customized Size

-

Application:

-

Waste Plastic Products

-

Feature:

-

High efficiency/High performance

-

Disc diameter (mm):

-

660MM

-

Main motor (kw):

-

55

Quick Details

-

Max.Production Capacity (kg/h):

-

1500

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

100 - 500 kg/h

-

Voltage:

-

220V/380V/415V/600V or customized

-

Dimension(L*W*H):

-

2700*2500*3900

-

Power (kW):

-

55

-

Weight (T):

-

2.1

-

Core Components:

-

Other

-

Name:

-

Plastic grinding machine crusher

-

Product name:

-

Crusher machine

-

Crushing material:

-

Types Waste Plastic

-

Color:

-

Customized Color

-

Usage:

-

Waste Plastic Cusher

-

Size:

-

Customized Size

-

Application:

-

Waste Plastic Products

-

Feature:

-

High efficiency/High performance

-

Disc diameter (mm):

-

660MM

-

Main motor (kw):

-

55

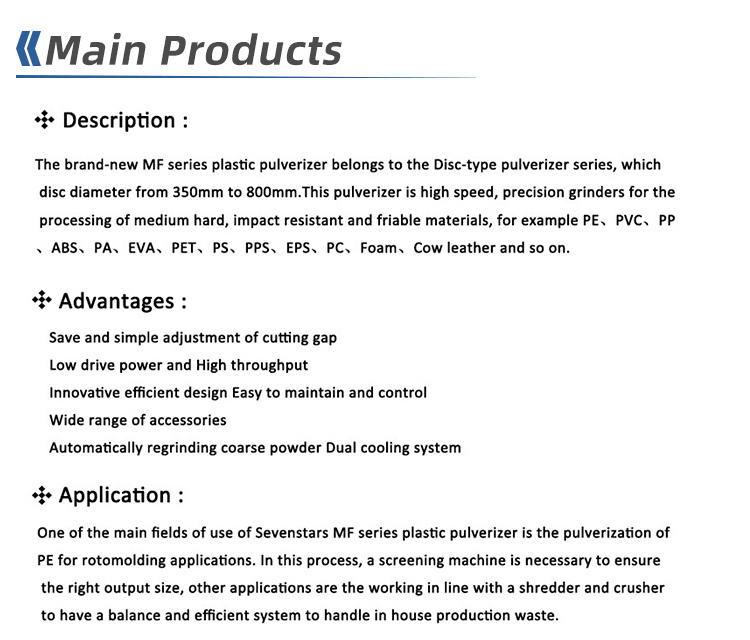

Products Description

Packing & Delivery

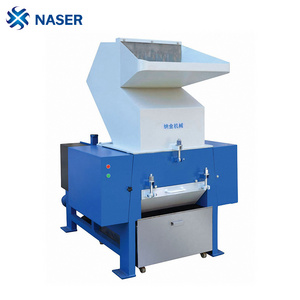

PVC Crusher Description:

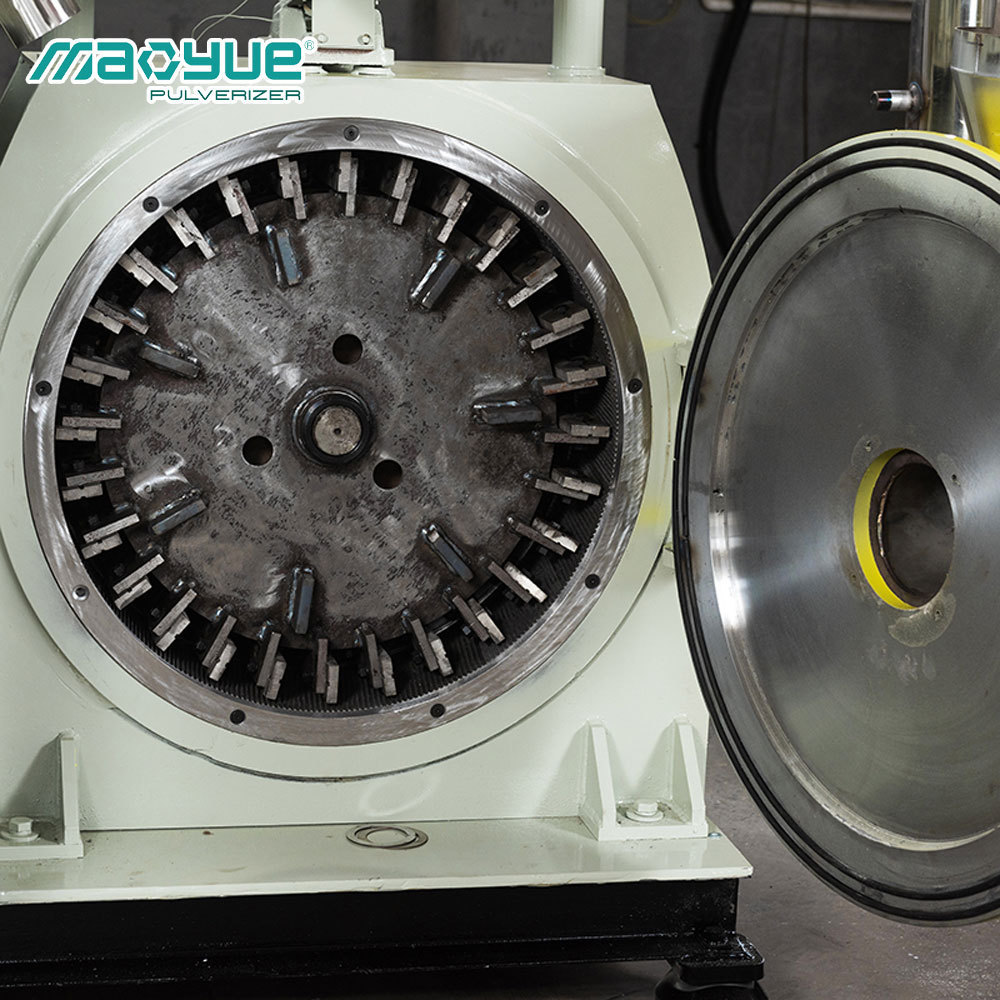

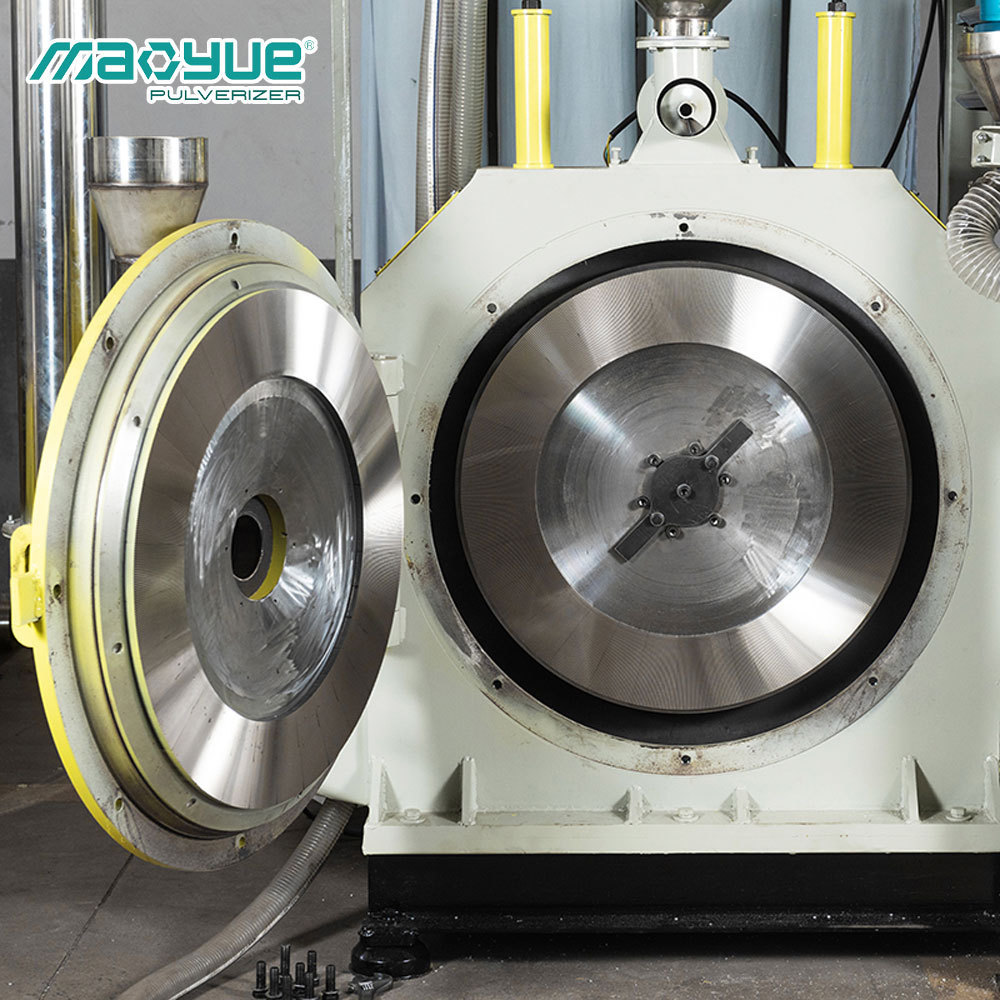

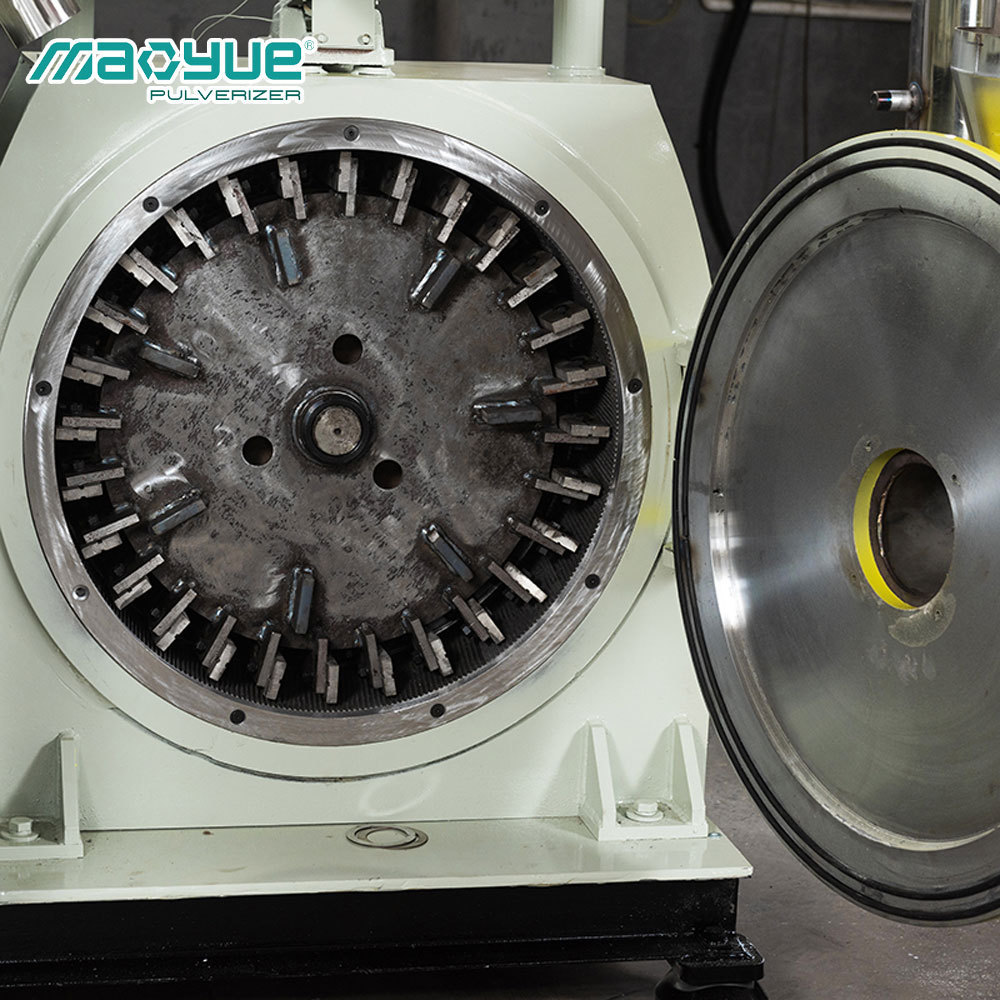

MF series plastic crusher is the broken material through the feeder into the body, driven by the spindle cutter for high-speed grinding of the material, the main machine diameter from 500 to 800 mm. The cutter head is controlled by the bearing seat assembly of the core component of the crusher, and a number of fixed knives form an outer ring. With the high-speed operation of the cutter head, the material is ground into powder, and the powder is collected by the fan and the cyclone system and then entered the screen.

PVC plastic crusher is mainly composed of motor, main engine, fan, cyclone barrel, feeder, vibrating screen, dust removal system,

etc.

According to the needs of customers, different applications, PVC crusher can be equipped with straight cutter head or split cutter head. You can also choose some accessories, such as iron removal feeder, screw feeder, pulse dust collector, metering and weighing machine.

MF series plastic crusher is the broken material through the feeder into the body, driven by the spindle cutter for high-speed grinding of the material, the main machine diameter from 500 to 800 mm. The cutter head is controlled by the bearing seat assembly of the core component of the crusher, and a number of fixed knives form an outer ring. With the high-speed operation of the cutter head, the material is ground into powder, and the powder is collected by the fan and the cyclone system and then entered the screen.

PVC plastic crusher is mainly composed of motor, main engine, fan, cyclone barrel, feeder, vibrating screen, dust removal system,

etc.

According to the needs of customers, different applications, PVC crusher can be equipped with straight cutter head or split cutter head. You can also choose some accessories, such as iron removal feeder, screw feeder, pulse dust collector, metering and weighing machine.

PE PP mill technical features:

1. The new tool is professionally designed and adopts high-density wear-resistant steel casting process with strong wear resistance.

2. New professional bearing seat assembly with high speed.

3. Easy installation and maintenance, just open the door to clean.

4. The whole powder making process is sealed, no dust leakage.

5. The machine has compact structure, small size and can save space.

6. The crusher adopts double cooling system of water and wind to prevent the host bearing and material from overheating.

7. SKF bearings, Siemens motors and other well-known brand accessories can be selected.

8. According to the customer's budget and material processing requirements, special plastic shredders can be developed.

1. The new tool is professionally designed and adopts high-density wear-resistant steel casting process with strong wear resistance.

2. New professional bearing seat assembly with high speed.

3. Easy installation and maintenance, just open the door to clean.

4. The whole powder making process is sealed, no dust leakage.

5. The machine has compact structure, small size and can save space.

6. The crusher adopts double cooling system of water and wind to prevent the host bearing and material from overheating.

7. SKF bearings, Siemens motors and other well-known brand accessories can be selected.

8. According to the customer's budget and material processing requirements, special plastic shredders can be developed.

Specification

|

Disc diameter (mm)

|

660mm

|

|

Dimension Length * Width * Height (mm)

|

2700*2500*3900

|

|

Main motor (kw)

|

55

|

|

Fan (kw)

|

5.5

|

|

Vibration motor (kw)

|

1.1

|

|

Discharger motor (kw)

|

0.75

|

|

Capacity (kg/h)

|

300-500

|

|

Cooling mode

|

Water, air

|

|

Plastic finishing size (mesh)

|

20-50

|

Hot Searches