- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SXPVC

-

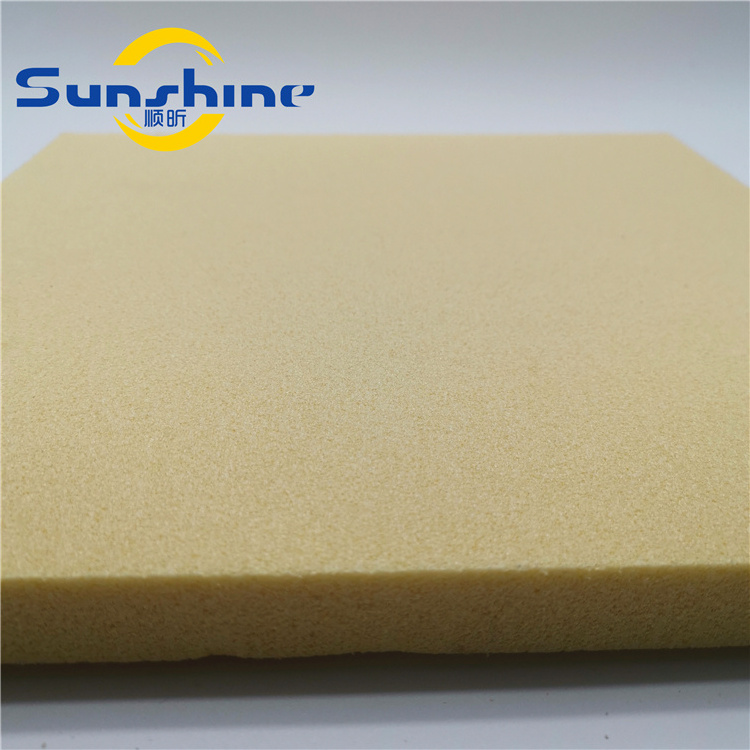

Thickness:

-

3mm, 3mm-50mm

-

Size:

-

Can be customized

-

Application:

-

Industry

-

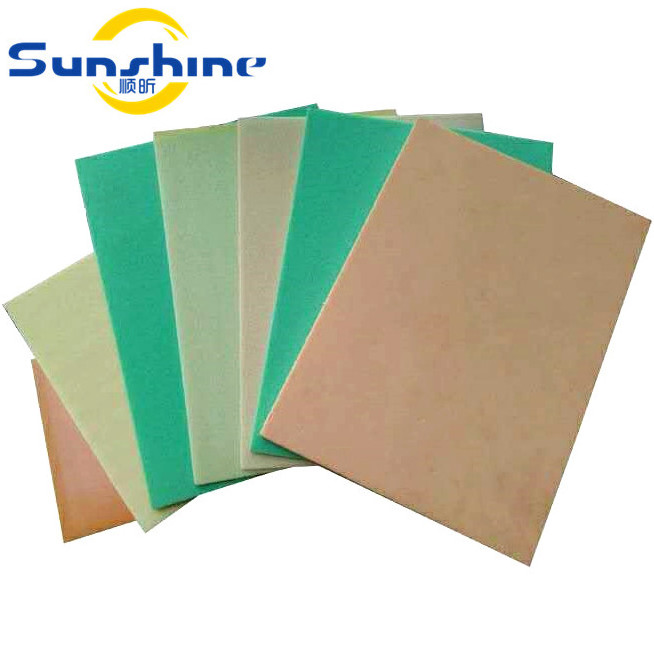

Color:

-

Yellow

-

Type:

-

Plain

-

Raw material:

-

PVC

-

Characteristics:

-

High Chemical Stability

Quick Details

-

Processing Service:

-

Cutting

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

NONE

-

Model Number:

-

SXPVC

-

Thickness:

-

3mm, 3mm-50mm

-

Size:

-

Can be customized

-

Application:

-

Industry

-

Color:

-

Yellow

-

Type:

-

Plain

-

Raw material:

-

PVC

-

Characteristics:

-

High Chemical Stability

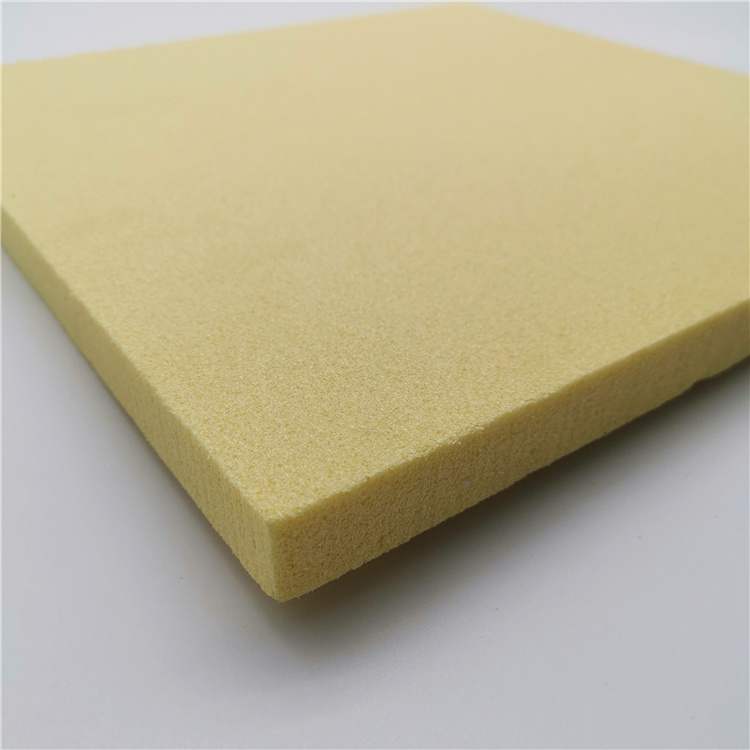

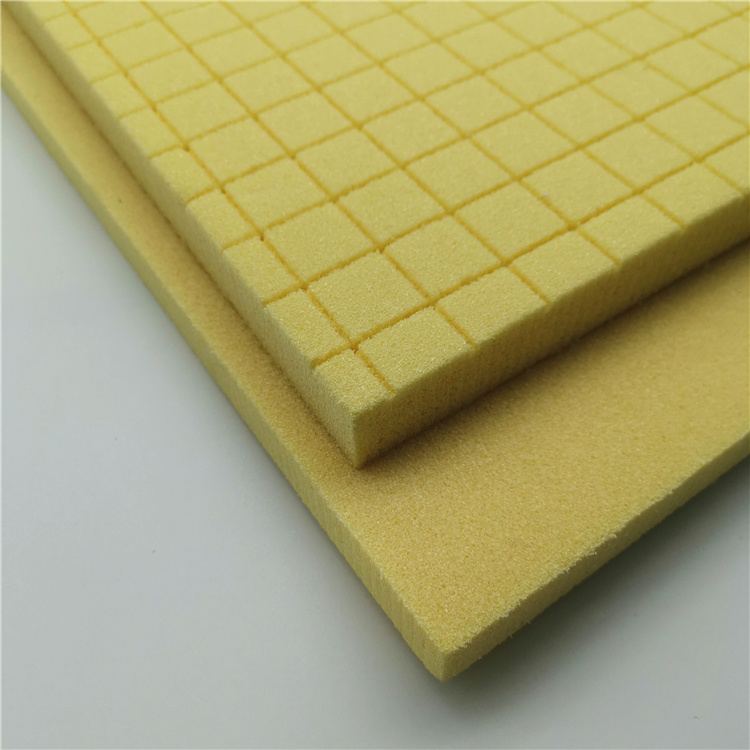

Products Description

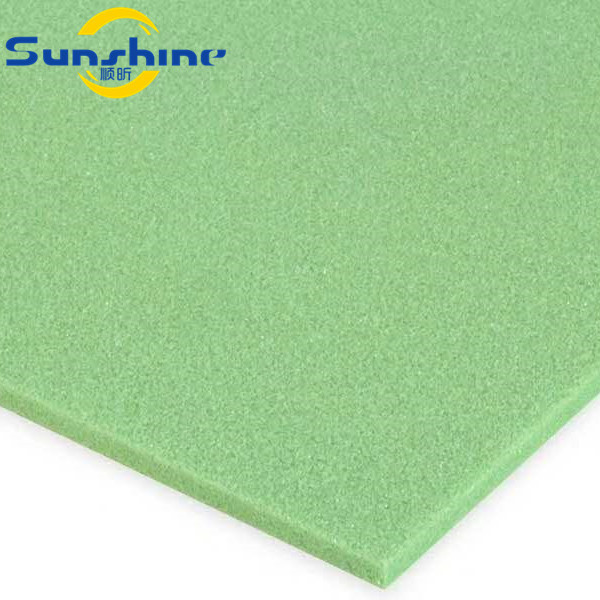

PVC foam core

material is one kind of closed-cell PVC rigid foam, which foams original panels by monomer solution copolymerization, and then processes into finished panels. Since foams’ property depends on resin matrix’s performance and cell structure, bunch of ring structures and cross-linked structures make resin matrix capable of high mechanical and thermal properties. With completed and uniform 100% closed-cell structure ensures structural stability. With the features of high temperature resistance, compression resistance and creep performance, it is suitable for a variety of composite molding process, such as vacuum infusion, RTM and casting molding process. Besides, resin compatibility, excellent chemical stability, low water absorption, noise insulation, low burning, with self-extinguishing, all of which make it to be applied to any field of sandwich industry, such as wind power, rail transit, shipbuilding, aerospace, construction and other industries. Especially in the wind power and shipbuilding industry, it has more advantages.

Product Property

Resin compatibility, good weather resistance, excellent chemical stability

Low burning, heat preservation, heat insulation, shock absorption

Low water absorption, not easy to be affected by damp, mildew

Good dimensional stability and machinability

Good specific stiffness, specific strength

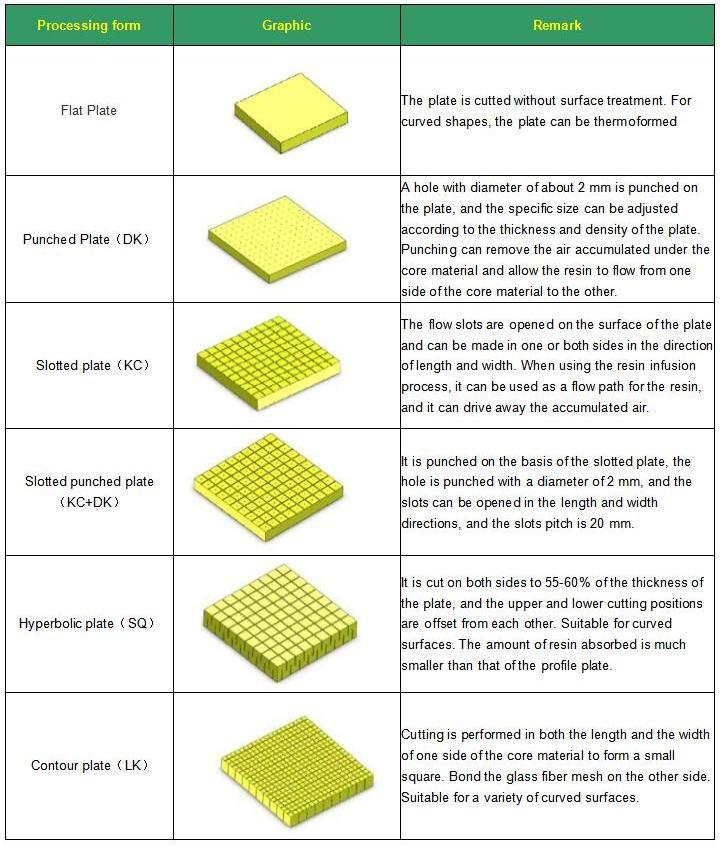

Typical Types

Applications

In

the FRP processing, in order to achieve lighter weight of the product, a sandwich structure is required, which requires the sandwich material to be lightweight, high-strength, water-resistant, weather-resistant and corrosion-resistant. PVC is the most commonly used cores for marine applications and wind blade manufacturing.

Besides, it is also widely used in structural parts such as car bodies, such as car interiors, front end of the car, supporting car doors, integral toilets and other car body equipment and decorative parts.

Packing and Shipping

PACKAGING

Product is manufactured in form of a roll wound on a paper tube. Each roll is packed in a plastic bag and placed within a cardboard carton. Positioned securely on to a pallet, strapped and covered.

Customized dimension and packaging also are welcome.

SHIPPING

For large cargo and not urgent needed, we recommend to ship by sea.

For urgent needed goods, by air is more suitable.

For samples, it is available to ship by DHL/Fedex/UPS/TNT/EMS or other way express

STORAGE

It is recommended that the product are stored in a cool and dry environment .

Recommended temperature range of storage is between 10-30℃ and relative humidity between 50-75%.

The product should remain in the packaging until just prior to use. Pallets should be stacked only one high.

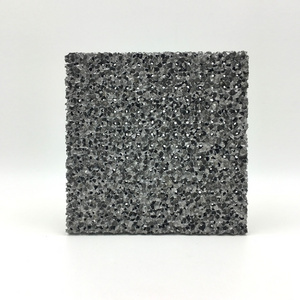

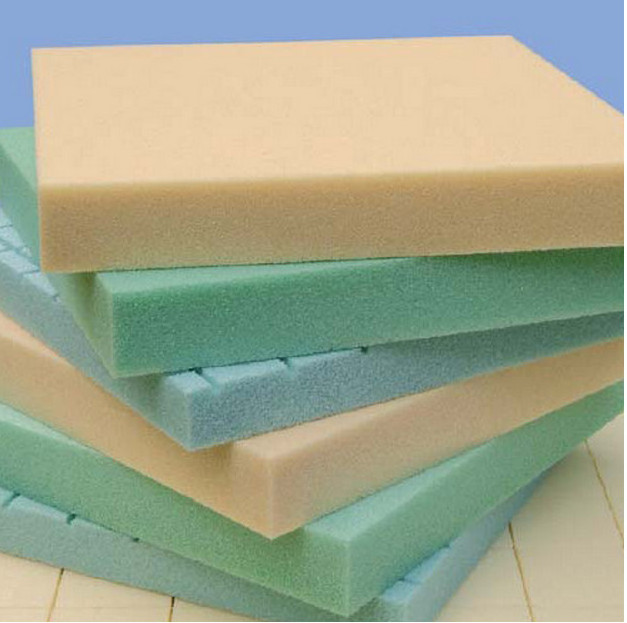

Related Products

Why Choose Us

High quality

Processes and batch tracing management

Raw material,carton,tube stock

Quality control management

Lead time

Lead time for new customer Within 7 days for trial order

Lead time for regular customer- we have their order in scheme Within 15 days for one container order

Considerate service

Customer oriented, OEM service

We accumulated rich experiences in client service

Deal with customer feedback within 24 hours

We take responsibility for every batch of products shipped out

Hot Searches