- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.8-1.2mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KYT

-

Weight:

-

3500 kg

-

Feeding width:

-

According to client's requirement

-

Product name:

-

Metal rain water gutter roof roll forming machine

-

Usage:

-

Building Roof

-

Raw material:

-

PPGI

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Control system:

-

PLC(detla) System

-

Machine type:

-

Roll Forming Mahcine

-

Cutting type:

-

Hydraulic Cutting

-

Thickness:

-

0.8-1.2mm Thickness

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

8-12m/min

-

Rolling thinckness:

-

0.8-1.2mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

KYT

-

Weight:

-

3500 kg

-

Feeding width:

-

According to client's requirement

-

Product name:

-

Metal rain water gutter roof roll forming machine

-

Usage:

-

Building Roof

-

Raw material:

-

PPGI

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Control system:

-

PLC(detla) System

-

Machine type:

-

Roll Forming Mahcine

-

Cutting type:

-

Hydraulic Cutting

-

Thickness:

-

0.8-1.2mm Thickness

Product Description

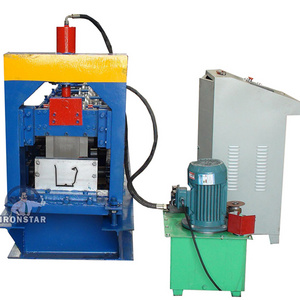

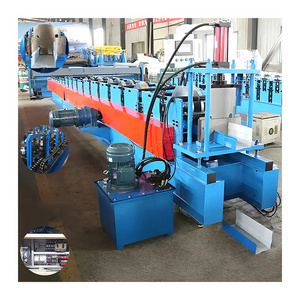

Metal Gutter Roll Former Machine

The gutter machine can use color steel or aluminum plate to make the gutter plate. The forming plate is rolled, closed, and then bent and narrowed by special equipment. It has good weather resistance, simple design, simple installation, safe and durable, and noble,Elegant. The gutter board can be sprayed with rich colors according to the individual needs of users, and its metal texture and beautiful shape can bring a strong expressive force to the building.

1. The whole machine is controlled by PLC, and multiple safety protections can be set to effectively avoid accidents;

2. The bed is made of steel plate welded parts and tempered to effectively eliminate internal stress and the body is not easy to deform;

3. The forming frame is welded by channel steel;

4. The roll shaft is made of 45# steel, which has been quenched and tempered;

5. The material of forming punching and shearing die is Gr12.

2. The bed is made of steel plate welded parts and tempered to effectively eliminate internal stress and the body is not easy to deform;

3. The forming frame is welded by channel steel;

4. The roll shaft is made of 45# steel, which has been quenched and tempered;

5. The material of forming punching and shearing die is Gr12.

Product Application

The gutter is used to collect and redirect rainwater away from a building's foundation. It helps prevent water damage to the structure and erosion of the surrounding soil. Additionally, gutters can also help prevent water from entering basements or crawl spaces.

The upper part is usually connected to the eaves, and the lower part is used to connect to the downspout.

Drawing and sample of gutter roll forming machine

Product Paramenters

|

Material thickness

|

0.4-0.8mm

|

|

Roll speed

|

8-12m/min

|

|

Roll steps

|

14

|

|

Main motor power

|

4 KW

|

|

Shaft diameter

|

80mm

|

|

Material of roller

|

45# steel polished and coated with chrome HRC55-60°

|

|

Material of bearing

|

high grade No.45 steel after treatment

|

|

Mode of cutting

|

Hydraulic cutting or flying saw

|

|

Material of scissors

|

Cr12 steel after treatment

|

|

Hydraulic station power

|

3 Kw

|

|

Control system

|

PLC Frequency Control System with touch screen

|

Working Flow

Component Of Machine

Hydraulic cutting

Once the metal strip has been formed into the desired profile, a cut-off system is used to separate the finished product from the remaining strip. stable cutting with high speed and low noise.

Main Forming Machine

After being forged, polished, heat-treated and finally chrome plated, they are very solid and not easy to wear. At the same time,the roof tiles are smooth without burrs

PLC Control System

It facilitates fully automatic production of machines and can set up different language systems according to customer needs

Decoiler

Mainly used to support steel coils, and manually uncoil and straighten the coil into the feeding table.

Oil Pump

Oil pumps are typically powered by an electric motor and connected to a tank that stores the oil. The pump draws oil from the tank and distributes it to various parts through fittings.

Receiving Table

Receiving table is to catch the pressed steel plate to prevent collision caused by the steel plate directly falling to the ground.

Related products

K style gutter roll forming machine

A K style gutter roll forming machine is a piece of equipment used to manufacture K style gutters. K style gutters are a popular type of gutter used in residential and commercial buildings. The roll forming machine is used to create the shape of the gutter by continuously bending and shaping a metal sheet into the desired profile. This machine is capable of producing gutters of various lengths and thicknesses, and it can be used with different types of metals, such as aluminum, steel, or copper. The finished gutters are then installed on the edge of a roof to collect and redirect rainwater away from the building.

Half round gutter roll forming machine

A half-round gutter roll forming machine is similar to a K style gutter roll forming machine but is specifically designed to manufacture half-round gutters. Half-round gutters have a semicircular shape and are often used in historical or traditional architectural styles. The roll forming machine for half-round gutters is designed to bend and shape metal sheets into the half-round profile, allowing for the production of gutters of various lengths and thicknesses. Like the K style gutter roll forming machine, it can work with different types of metals such as aluminum, steel, or copper. The finished half-round gutters are installed on the edge of a roof to collect and redirect rainwater away from the building, similar to K style gutters.

Downspouts roll forming machine

A downspouts roll forming machine is a piece of equipment used to manufacture downspouts, also known as downpipes or leaders. Downspouts are vertical pipes that are used to carry rainwater from the gutters to the ground or drainage system. The roll forming machine is designed to bend and shape metal sheets into the desired profile for downspouts, allowing for the production of downspouts of various lengths and thicknesses. This machine can work with different types of metals such as aluminum, steel, or copper. The finished downspouts are then installed vertically on the exterior of a building to direct rainwater away from the foundation and prevent water damage.

Company Show

Botou Kaiyite Cold Bending Machinery Co., Ltd is a professional roll forming machine manufacturer in Cangzhou city, China that supply turn-key solutions for roller shutter door machine and metal door frame roll forming machines . We have experienced technicians and designers, who started machine designing and making since 2007, to ensure we are the highest standard in the same industry.

You can get any machines according to your needs. Because we can design and produce different machines according to your requirements, which are popular in international markets. Besides we manufacture some auxiliary equipment as accessory machine to our major products. This includes decoiler , output table , slitting machine and so on .

We has shipped its designed roll forming machine equipment all over the world. As a result it has established long-run business relationship with many esteemed international companies under mutual benefits! Because all technical requirements about the machinery have been greatly satisfied, our shutter door machine and metal door frame machine would manufacture exquisite final products as per industry standard in the international markets.

Why choose us

WHY CHOOSE US:

1.Over 20 years of experience.

2.Customized according to customer requirements with OEM ODE Services.

3.Favorable price and easy operation.

4.Professional technical team strictly controls every step of production to ensure the quality of each equipment.

1.Over 20 years of experience.

2.Customized according to customer requirements with OEM ODE Services.

3.Favorable price and easy operation.

4.Professional technical team strictly controls every step of production to ensure the quality of each equipment.

5.Provide technical guidance, production, installation, commissioning and maintenance services for our customers.

FAQ

1. who are we?

We are based in Hebei, China, start from 2016,sell to Western Europe(25.00%),South America(20.00%),Mid East(20.00%),Southeast Asia(20.00%),Africa(15.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shutter Door Roll Forming Machine, Roofing Sheet Roll Forming Machine, Floor Deck Roll Forming Machine, Stud And Track Roll Forming Machine, Door Frame Roll Forming Machine

4. why should you buy from us not from other suppliers?

1. High quality materials for machine ; 2. Strict quality control ; 3. Professional and fast solutions for aftersale service ;

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Arabic,French,Russian,Italian.

We are based in Hebei, China, start from 2016,sell to Western Europe(25.00%),South America(20.00%),Mid East(20.00%),Southeast Asia(20.00%),Africa(15.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Shutter Door Roll Forming Machine, Roofing Sheet Roll Forming Machine, Floor Deck Roll Forming Machine, Stud And Track Roll Forming Machine, Door Frame Roll Forming Machine

4. why should you buy from us not from other suppliers?

1. High quality materials for machine ; 2. Strict quality control ; 3. Professional and fast solutions for aftersale service ;

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Arabic,French,Russian,Italian.

Hot Searches