- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Size

-

Weight:

-

750kg

-

Processing capacity (cubic meter/h):

-

3.1-6.1 \ 1020-1320

-

Overall diamensions(mm):

-

260*320*646-3690*3584*3475

-

Diameter:

-

125-550

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Certification:

-

ISO 9001, CE, ISO9001:2008

Quick Details

-

Production Capacity:

-

99%, 11-600m3/h

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Chaishang

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Size

-

Weight:

-

750kg

-

Processing capacity (cubic meter/h):

-

3.1-6.1 \ 1020-1320

-

Overall diamensions(mm):

-

260*320*646-3690*3584*3475

-

Diameter:

-

125-550

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Certification:

-

ISO 9001, CE, ISO9001:2008

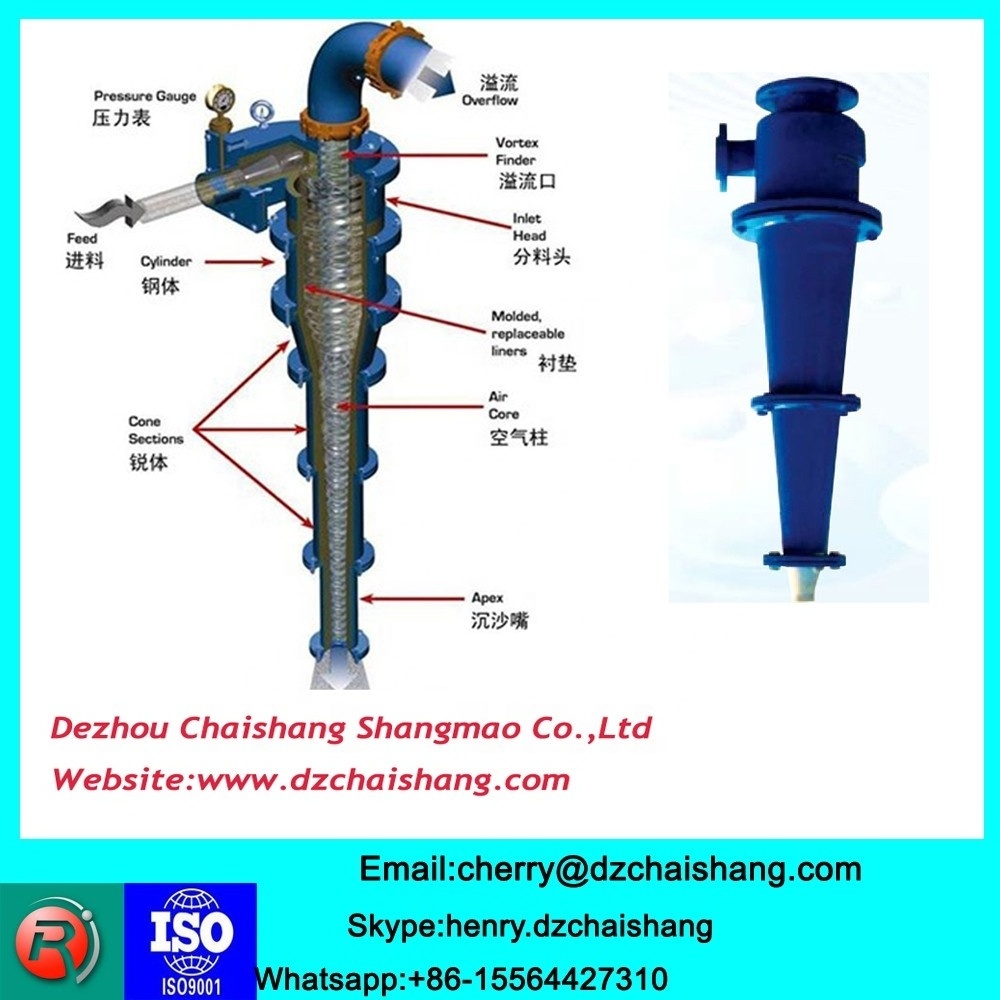

China high quality mine separator polyurethane hydrocyclone cyclone separator

A hydrocyclone is a device to classify, separate or sort particles in a liquid suspension based on the ratio of their centripetal force to fluid resistance. This ratio is high for dense (where separation by density is required) and coarse (where separation by size is required) particles, and low for light and fine particles.

Remarks:

1. Please mark out the model, quantity and spiral direction of the classifier while ordering.

2. The lengthened type (lengthening of sand return zone, lengthening of settling zone) can be designed and made according to customer demands, and the lengthening amount should be noted.

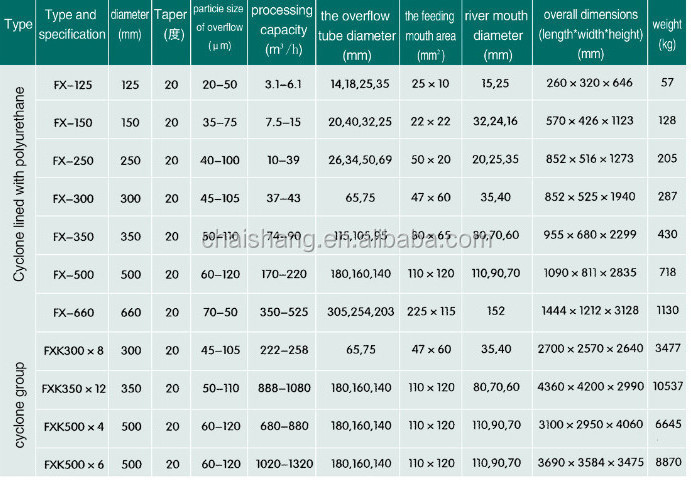

| 1.Specification of hydrocyclone |

Metal Mine Hydrocyclone, also called hydrocyclone design , is widely applied in mine-chosen technique in various metal mines.

In closed circuit grinding system, the hydrocyclone design features high classification efficiency and fine overfall fineness under high mine concentration. Classification efficiency is higher for 5-10% than common screw grader. It benefits for enhancing grader utilizing coefficient. Choose proper specification and mode concentration. This is precondition of getting the most optimized work condition.

| 2.Features of hydrocyclone |

• Low capital cost.

• High efficiency for 5 - 200 micron particles.

• Lack of moving parts reduces wear.

• Continuous or batch removal of underflow requires virtually no downtime for maintenance or recovery.

• Small relative to other separation equipment.

• Can operate at a wide range of temperatures and pressures.

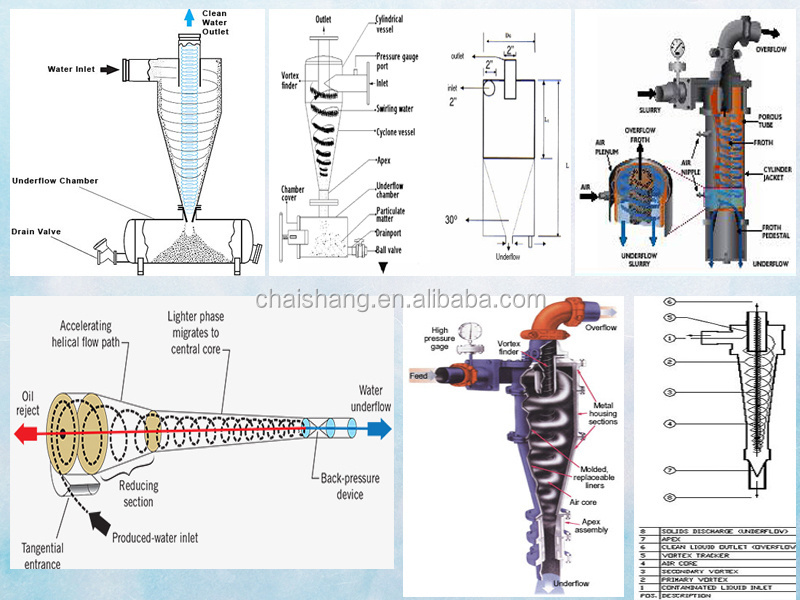

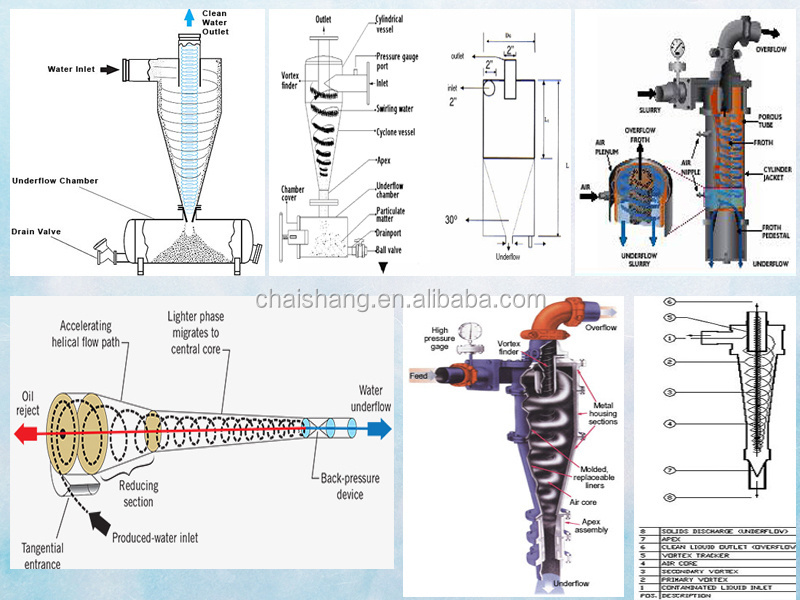

| 3 .structure of hydrocyclone |

|

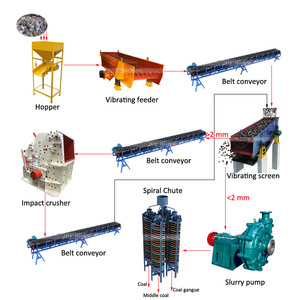

4.Working principle

of hydrocyclone

|

|

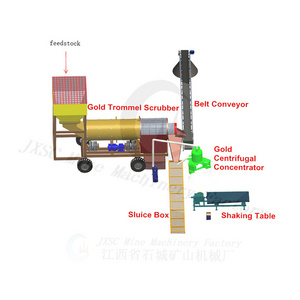

6.Application of hydrocyclone

|