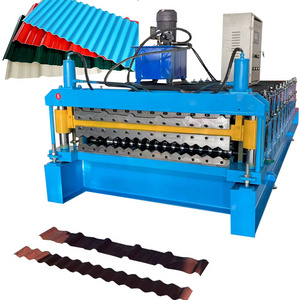

The two layers can not work at the same time, and it is manual changed by clutch.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Bogong

-

Voltage:

-

380V Or Customized

-

Dimension(L*W*H):

-

10500*1550*1650mm

-

Weight:

-

9000 kg

-

Feeding width:

-

1000/1220mm

-

Machine Frame:

-

H400 Beam

-

Suitable Material:

-

Color Steel Galvanised Sheet

-

Material Thickness:

-

1000/1200mm

-

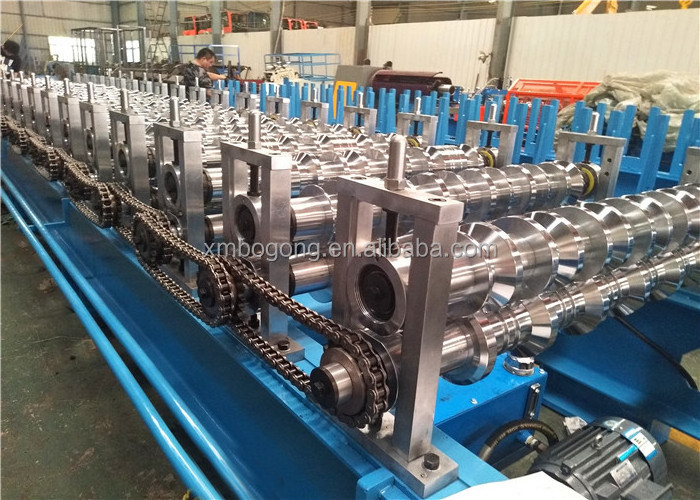

Shaft Material:

-

45# steel

-

Shaft Diameter:

-

75mm Solid Shafts Diameter

-

Roller Material:

-

45#steel Chrome Plated

-

Forming Station:

-

18-20 Stations

-

Forming Speed:

-

15-25m/min

-

Control System:

-

PLC(detla) System

-

Driving Motor:

-

7.5KW/11KW

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

20-25m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Bogong

-

Voltage:

-

380V Or Customized

-

Dimension(L*W*H):

-

10500*1550*1650mm

-

Weight:

-

9000 kg

-

Feeding width:

-

1000/1220mm

-

Machine Frame:

-

H400 Beam

-

Suitable Material:

-

Color Steel Galvanised Sheet

-

Material Thickness:

-

1000/1200mm

-

Shaft Material:

-

45# steel

-

Shaft Diameter:

-

75mm Solid Shafts Diameter

-

Roller Material:

-

45#steel Chrome Plated

-

Forming Station:

-

18-20 Stations

-

Forming Speed:

-

15-25m/min

-

Control System:

-

PLC(detla) System

-

Driving Motor:

-

7.5KW/11KW

Products Description

|

Items

|

Parameters

|

|

Material Thickness

|

0.3-0.8mm

|

|

Forming Speed

|

15-25m/min

|

|

Shaft Material

|

45# steel quenching

|

|

Shaft Diameter

|

75mm, Solid

|

|

Roller Material

|

45# steel, hard Chrome Coated

|

|

Driving Motor

|

11KW

|

|

Hydraulic Motor

|

4KW

|

|

Control System

|

PLC Delta, Simenz or Mitsubish

|

|

Suitable Material

|

Prepainted steel, Galvanized steel

|

|

Material Width

|

1000/1220mm

|

|

Two Layers Work at The Same Time or Not

|

Not

|

|

Cutting Blade Material

|

Cr12

|

|

Cutting Type

|

No Slug Cutting

|

Feeding Table

This double layer roof roll forming machine has matched with two sets feeding tables, one layer one set. And we have designed leading rollers for compacting material head.

Hot Searches