- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3000x4150x2500mm

-

Year:

-

2024

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6000 KG

-

After-sales Service Provided:

-

Field maintenance and repair service

-

After Warranty Service:

-

Online support

-

Marketing Type:

-

New Product 2024

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

dongnuo rubber

-

Voltage:

-

380v or Required

-

Dimension(L*W*H):

-

3000x4150x2500mm

-

Year:

-

2024

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6000 KG

-

After-sales Service Provided:

-

Field maintenance and repair service

-

After Warranty Service:

-

Online support

-

Marketing Type:

-

New Product 2024

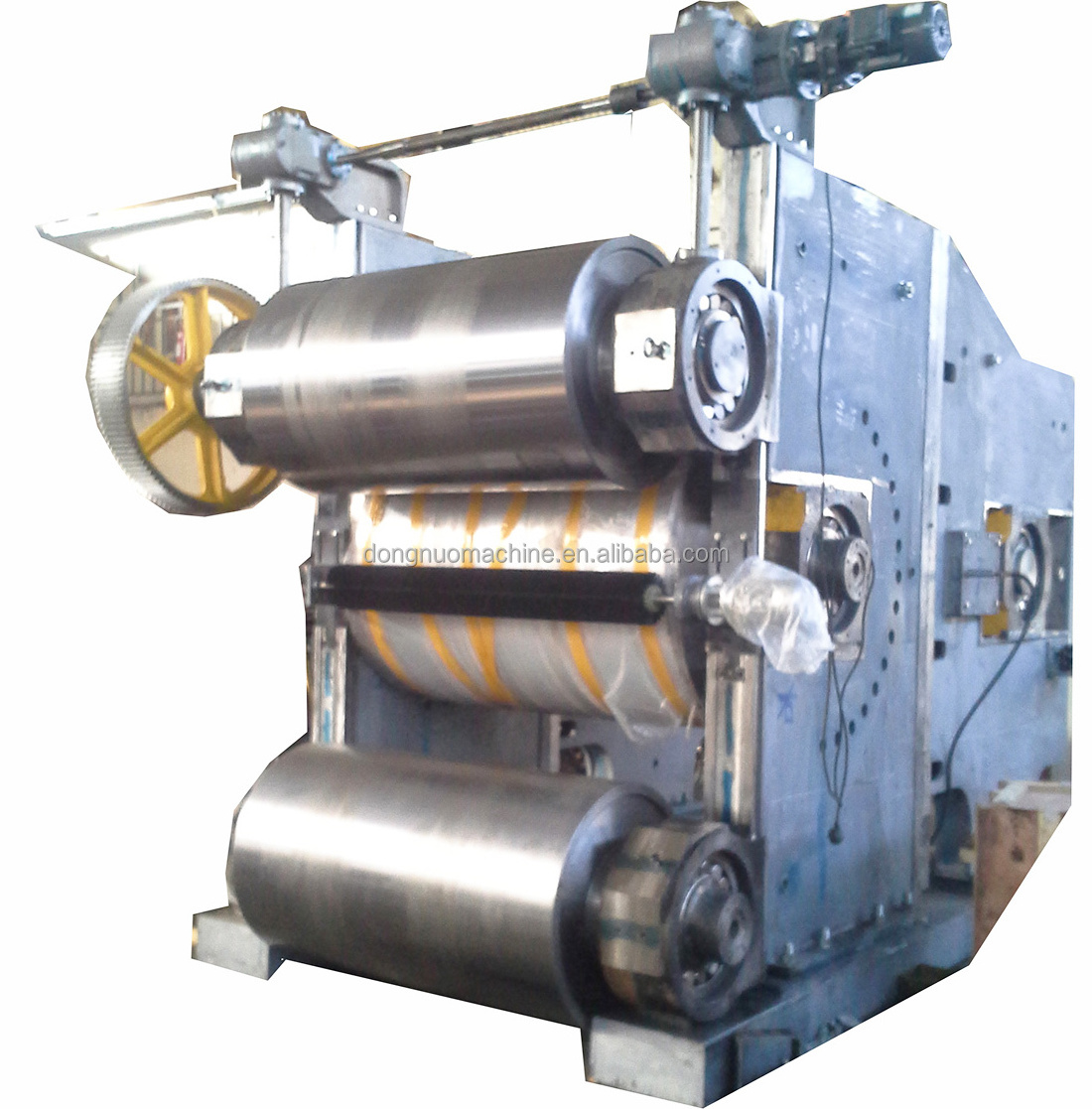

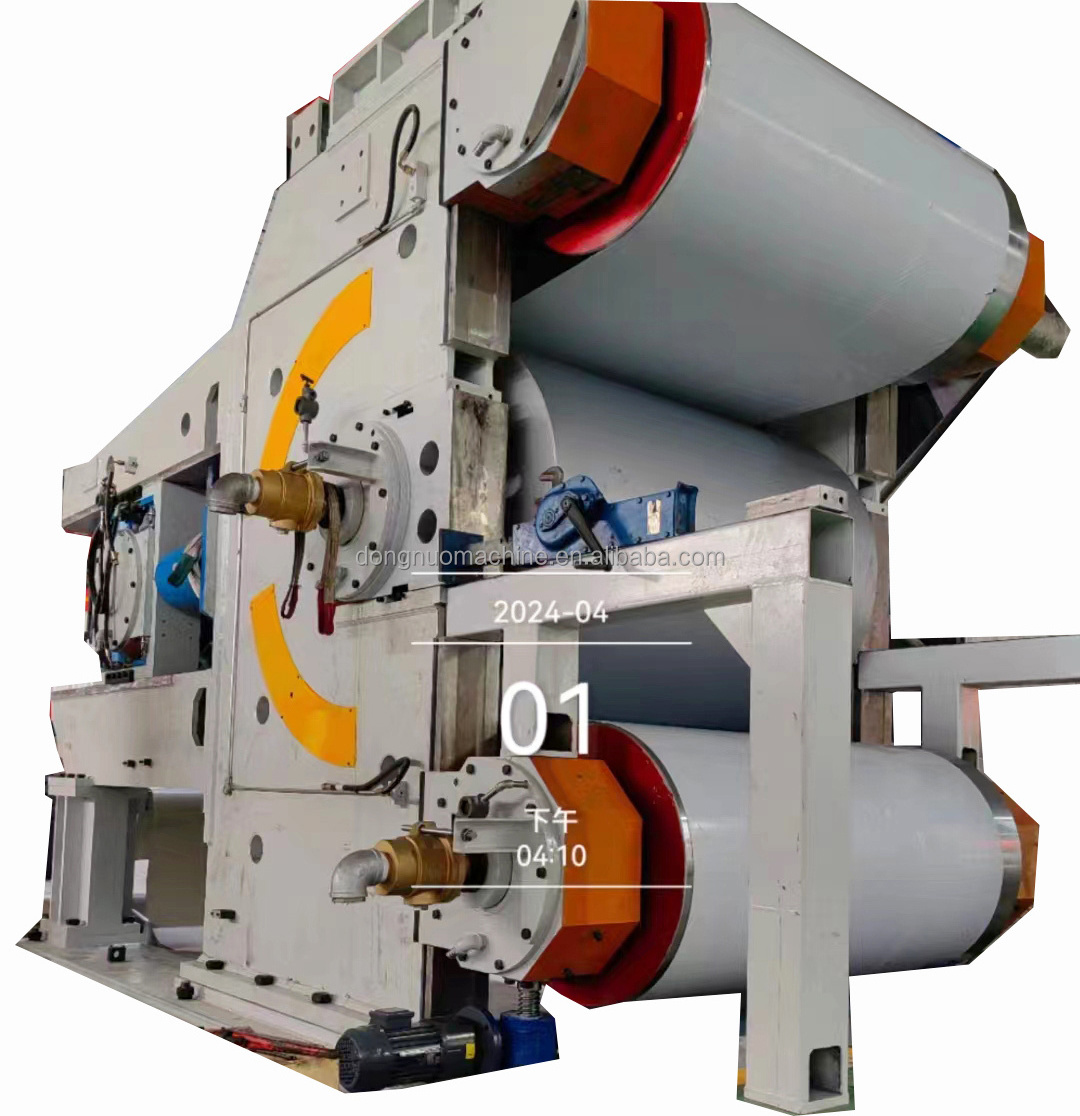

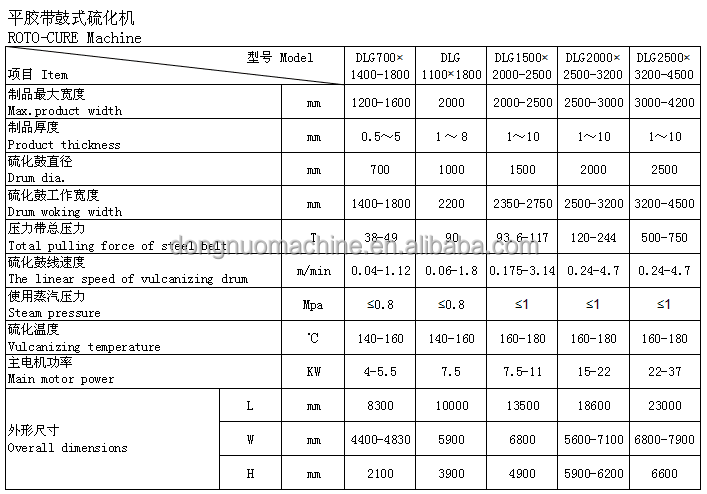

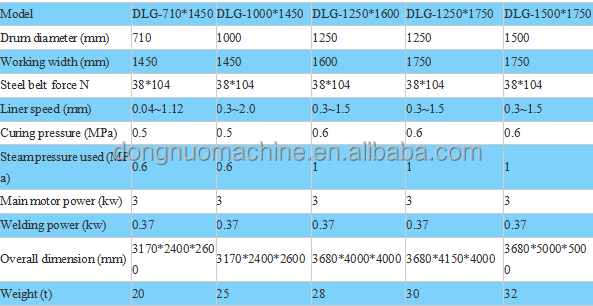

Drum type Rotary Curing Machine rotocure machine

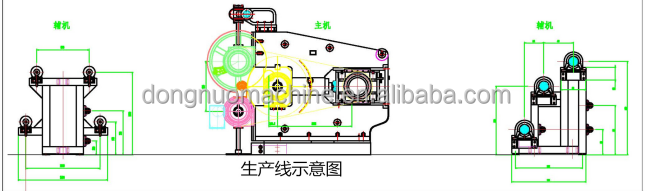

Drum vulcanizing machines are used to continuously vulcanize various rubber sheets, light conveyor belts and transmission belts, printing rubber cloths, rubber and plastic floors, waterproof membranes, heavy-duty conveyor belts, fuel tanks or hull linings and other plate-shaped products.

Product Description

Features of the drum vulcanizing machine:

The product can be continuously vulcanized. The surface of the product is smooth, the thickness is uniform, the interior is dense, there are no joints that are repeatedly vulcanized twice, there are no dark edges in the joints, and annular joint-less vulcanization can be achieved. Since vulcanization is carried out continuously, automated operations can be realized. Not only can the number of operators be reduced, but the labor intensity can also be greatly reduced. For plate and belt products that require high surface accuracy or have continuous patterns, its advantages are particularly significant, and the product performance can be uniform throughout the entire length.

Packing & Delivery

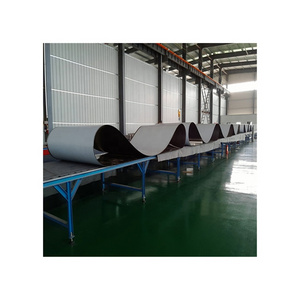

Customer Photo

Hot Searches