- Product Details

- {{item.text}}

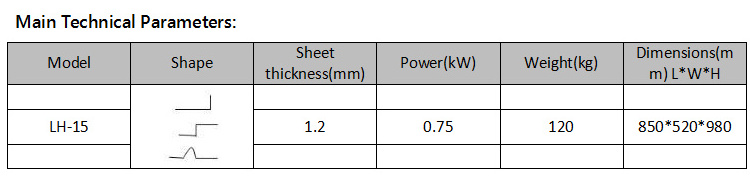

Quick Details

-

Thickness:

-

0.4-1.2mm

-

Motor power:

-

0.75kw

-

Raw Material:

-

Carbon Steel

-

Weight:

-

120kg

-

Dimension:

-

850*520*980mm

-

function-01:

-

elbow forming and flanging

-

function-02:

-

roll cutting and beading and s

-

Certification:

-

CE/SGS/BV/ISO9001

Quick Details

-

Place of Origin:

-

Anhui, China

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support, Engineers available to service machinery overseas

-

Type:

-

LH-15

-

Thickness:

-

0.4-1.2mm

-

Motor power:

-

0.75kw

-

Raw Material:

-

Carbon Steel

-

Weight:

-

120kg

-

Dimension:

-

850*520*980mm

-

function-01:

-

elbow forming and flanging

-

function-02:

-

roll cutting and beading and s

-

Certification:

-

CE/SGS/BV/ISO9001

Product Application

This electric bead roller machine is mainly used for round duct sheet metal grooving/beading and connection. It's adjustable for different metal sheet.

such as for leveling metal sheets, shearing sheets, corrugating plates, etc. Power Swaging machine and Universal Hand beading machine can be selected.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1.Are you factory or foreign trade company?

We are the manufacturer and do our own exporting team for more than 15 years' experience.

2.How can we operate the machine?

Our machines are very easy to operate.We have detailed installation and operating instructions attached.

We will arrange our engineers available to service machinery overseas for HVAC duct production lines.

3.How long warranty can you provide?

Our machine warranty is one year and life time service after sales.

4. What are your payment terms?

We support T/T, L/C, Western Union and so on. Other ways can also be received after we both sides discussion and agreement.

Pittsburgh Lock former

98.8% Response Rate

Spiral Tubeformer (Mould Type)

91.8% Response Rate

Angle Iron Rolling Machine

96.7% Response Rate