- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Miining

-

Color:

-

Black

-

Advantage:

-

Wear Resistant

-

Delivery time:

-

7-10 Days or according to the quantity

-

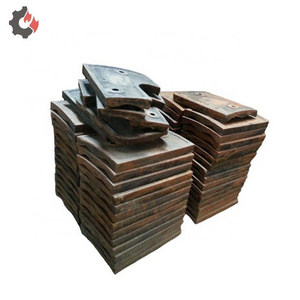

Part name:

-

liner plate

-

Customized:

-

Accepted

-

Size:

-

Customize Size

Quick Details

-

Weight (KG):

-

10

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DIZHUO

-

Application:

-

Miining

-

Color:

-

Black

-

Advantage:

-

Wear Resistant

-

Delivery time:

-

7-10 Days or according to the quantity

-

Part name:

-

liner plate

-

Customized:

-

Accepted

-

Size:

-

Customize Size

Products Description

The rubber liner is gradually replacing the manganese steel liner. It can bear strong impact of resistance. The yield of your grinding circuits is highly dependent on your mill's rubber liner. Select right of your rubber liner supplier carefully will make sure your milling process runs at maximum capacity and availability.

Rubber liners is usually suitable for wet grinding, the temperature is not higher than 80 degrees of normal work, but for high-temperature dry grinding, strong acid and Alkali resistance, oil resistance and other special environment, need to be explained in advance by separate design formula and custom made, in addition, the storage process must be placed in indoor proper custody, it intends the rubber liners to prevent outdoor exposure under the high temperature and rain.

According to the purpose, the rubber liners is divided used in: AG, SAG, ball, pebble, rod & batch mills, FGD, SMD and continuous mills. According to the shape, it is divided into overflow type, grid type and multi-bin type, which can meet the requirements of one-stage rough grinding and two-stage fine grinding.

We can customize all kinds of high-quality and high wear-resistant rubber liners

according to the needs of each customer.

|

Item Name

|

Rubber mill liner

|

|

Tensile Strength

|

228 Kg/cm2

|

|

Elongation at Break

|

470%

|

|

Hardness

|

Shore A 68(±5)

|

|

Tear Strength

|

81Kg/cm

|

|

Heat Resistant

|

Up to 90 ℃

|

|

Base Polyurethane/Rubber

|

Natural & Synthetic

|

|

custom

|

yes

|

The Advantages of Dizhuo Rubber Mill Liners

1.LOWER COST

These are very cost effective as COST PER TON OF ORE GRIND IS LOWER.

2.LONGER LIFE

Rubber Mill liners have LONGER OPERATIONAL LIFE.

3.LESS MAINTENANCE

Rubber Mill Liners are engineered to resist abrasion, increasing the interval between maintenance intervals.

4.FASTER / SAFER

Rubber Components are lighter and easier to handle

5.REDUCED NOISE

Rubber Mill Liners REDUCE THE NOISE LEVEL to safer levels by absorbing impact against the shell

6.REDUCED WEIGHT

Rubber Liners are about 1/8 by weight of steel liners of same size

7.REDUCED INVENTORY

Rubber Mill Liners have a PREDICTABLE WEAR RATE so inventory planning is easy.

8.NO LEAKAGE

Rubber mill liners seal to the shell eliminating slurry leakage from the mill.

9.REDUCED POWER

Light weight of Rubber Mill reduces the current draw of the mill.

10.INCREASED BEARING / PINION LIFE

Reduced weights and leak proof fixing increase the normal life of the Pinion Gear and Bearings.

11.DEDICATED AFTER SALES SERVICE

We have fully trained Service team to assist you.

12.EASY TO MANAGE SPARES

Shorter lead times insure quick delivery of required spares

Application:

* - AG MILL

* - SAG MILL

* - FGD MILL

* - CONTINUOUS MILL

* - INTERMI TTENT MILL

* - TWO-STAGE BALL MILL

Products Show

Hot Searches