1.Low heat storage;

2.Resistant to Non-Ferrous Metals;

3.Excellent resistance to thermal shock and chemical attack;

4.Resists oxidation and reduction;

5.High mechanical strength at high temperature;

6.Can be machined, cut and shaped easily

7.High rigidity and light weight

- Product Details

- {{item.text}}

Quick Details

-

Thermal Conductivity:

-

0.165

-

Thickness:

-

6/10/15/20/25/30/40/50 Mm

-

Width:

-

400/600mm

-

Length:

-

600-1220mm

-

Working Temperature:

-

1100C/1260C/1360C/1430C

-

Shrinkage (1800℉, 3h):

-

3 (24hours)

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Standard

-

Brand Name:

-

RONGSHENG

-

Product name:

-

Ceramic fiber board

-

Color:

-

White

-

Size:

-

Customized Size

-

Raw material:

-

Ceramic fiber

-

BULK DENSITY:

-

260-320

-

Feature:

-

Low Heat Loss and Storage

-

Sample:

-

Avaliable

-

Keyword:

-

Ceramic Fiber Board

-

Advantage:

-

Excellent resistance to thermal shock and chemical attack

Quick Details

-

Chemical Composition:

-

AL2O3+SIO2+ZrO2

-

Ultimate Strength (≥ MPa):

-

0.5MPa

-

Fiber Diameter:

-

3-5

-

Thermal Conductivity:

-

0.165

-

Thickness:

-

6/10/15/20/25/30/40/50 Mm

-

Width:

-

400/600mm

-

Length:

-

600-1220mm

-

Working Temperature:

-

1100C/1260C/1360C/1430C

-

Shrinkage (1800℉, 3h):

-

3 (24hours)

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Standard

-

Brand Name:

-

RONGSHENG

-

Product name:

-

Ceramic fiber board

-

Color:

-

White

-

Size:

-

Customized Size

-

Raw material:

-

Ceramic fiber

-

BULK DENSITY:

-

260-320

-

Feature:

-

Low Heat Loss and Storage

-

Sample:

-

Avaliable

-

Keyword:

-

Ceramic Fiber Board

-

Advantage:

-

Excellent resistance to thermal shock and chemical attack

Products Description

Ceramic fiber board

is a high-performance insulating product formed by ceramic fiber and adhesive in vacuum. It is flat, ceramic materials are evenly distributed, and has excellent heat insulation performance. Due to its low thermal conductivity and low heat storage, no inflation during heating can reduce energy cost and cycle time, and protect the refractory surface from thermal shock and chemical attack. Therefore, it is an ideal product for fire resistance, heat insulation and heat insulation.

Specification

|

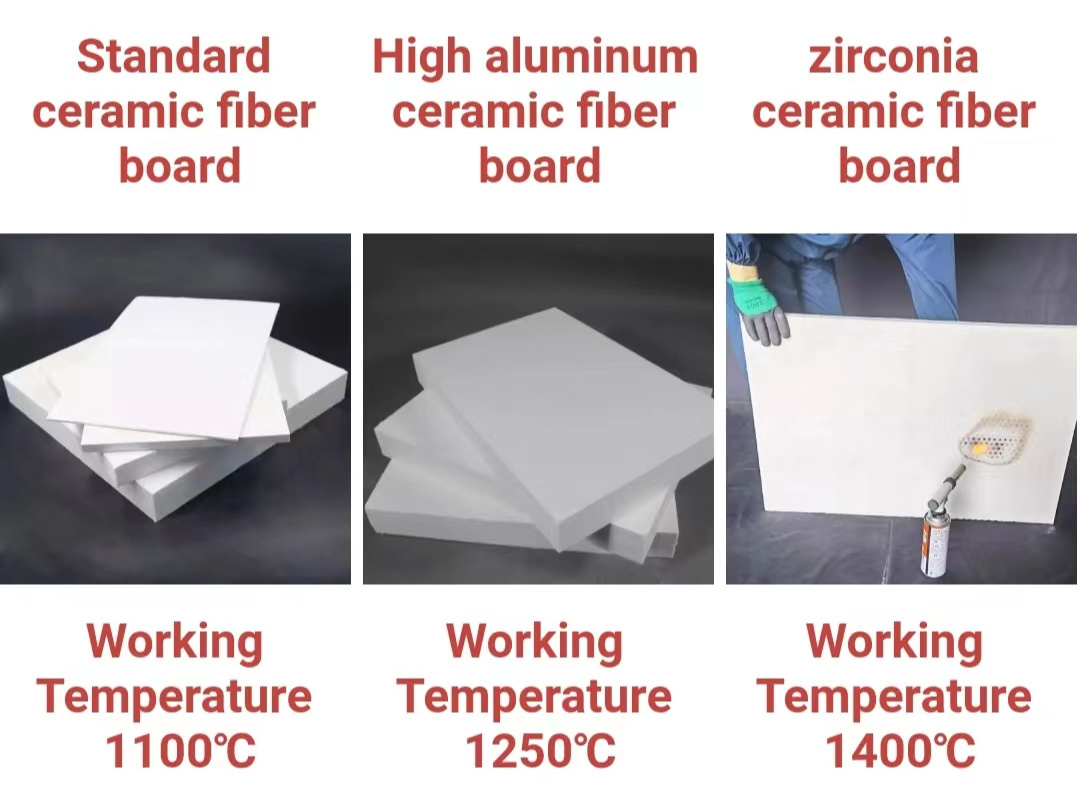

Standard ceramic fiber blanket - working temperature 1050 ℃

High-alumina ceramic fiber blanket - working temperature 1260 ℃

Zirconia ceramic fiber blanket - working temperature 1350 ℃

Thickness 6-50mm

|

|

|

|

|

|

|

|

|||||||

|

Type

|

|

COM

|

ST

|

HP

|

HA

|

Zir-Alu

|

HZ

|

|||||||

|

Classified Temp.

|

|

1100℃

(1983℉)

|

1260℃

(2300℉)

|

1260℃

(2300℉)

|

1360℃

(2480℉)

|

1400℃

(2550℉)

|

1430℃

(2600℉)

|

|||||||

|

Working Temp.

|

|

<1000℃

(2012℉)

|

1050℃

(1922℉)

|

1100℃

(2012℉)

|

1260℃

(2192℉)

|

1260℃

(1192℉)

|

1350℃

(2462℉)

|

|||||||

|

Color

|

|

white

|

white

|

white

|

white

|

white

|

white

|

|||||||

|

Density(kg/m3)

|

|

260-320

(16-20lb/ft3)

|

260-320

(16-20lb/ft3)

|

260-320

(16-20lb/ft3)

|

260-320

(16-20lb/ft3)

|

260-320

(16-20lb/ft3)

|

260-320

(16-20lb/ft3)

|

|||||||

|

Linear Shrinkage (%)

(24 hrs)

|

|

-3

(1000℃/1832℉)

|

-3

(1000℃/1832℉)

|

-3

(1100℃/2012℉)

|

-3

(1250℃/2282℉)

|

-3

(1000℃/2012℉)

|

-3

(1350℃/2462℉)

|

|||||||

|

Thermal conductivity

(W/M.K)

|

|

0.085

(400℃/752℉)

0.132

(800℃/1472℉)

0.180

(1000℃/2012℉)

|

0.085

(400℃/752℉)

0.132

(800℃/1472℉)

0.180

(1000℃/2012℉)

|

0.085

(400℃/752℉)

0.132

(800℃/1472℉)

0.180

(1000℃/2012℉)

|

0.085

(400℃/752℉)

0.132

(800℃/1472℉)

0.180

(1000℃/2012℉)

|

0.085

(400℃/752℉)

0.132

(800℃/1472℉)

0.180

(1000℃/2012℉)

|

0.085

(400℃/752℉)

0.132

(800℃/1472℉)

0.180

(1000℃/2012℉)

|

|||||||

|

Compression Strength

(Mpa) |

|

0.5

|

0.5

|

0.5

|

0.5

|

0.5

|

0.5

|

|||||||

|

Chemical(%) |

Al2O3

|

44

|

46

|

47-49

|

52-55

|

45-46

|

39-40

|

|||||||

|

|

Al2O3+SiO2

|

96

|

97

|

99

|

99

|

-

|

-

|

|||||||

|

|

Al2O3+SiO2+ZrO2

|

-

|

-

|

-

|

-

|

|

99

|

|||||||

|

|

ZrO2

|

-

|

-

|

-

|

-

|

.5-7

|

15-17

|

|||||||

|

|

Fe2O3

|

<1.2

|

<1.0

|

0.2

|

0.2

|

0.2

|

0.2

|

|||||||

|

|

Na2O+K2O

|

≤0.5

|

≤0.5

|

0.2

|

0.2

|

0.2

|

0.2

|

|||||||

|

Size(mm)

|

|

1200*1000mm(47″*40″); 1000*600mm(40″*36″);900*600mm(24″*36″)

20-50mm(1″/2″)thickness |

|

|

|

|

|

|||||||

Application

1.Cement industry kiln back lining thermal insulation

2.Ceramic industry lining of various kilns for thermal insulation, Kiln door, kiln car and dilatation joint, etc,.

3.Petrochemical and metallurgy industries Heat treatment furnace kiln back lining thermal insulation, mechanic and metallurgy heating furnace, thermal treatment furnace and others industrial furnace and hot face internal lining

4.Glass industry Glass kiln lining and back lining thermal insulation

5.Aluminium industry reduction cell firebricks back linings, high temperature reaction, heating device-wall lining and back linings

6.Board over blanket hot face lining

7.Back-up insulation to brick & castable

Why Choose Us

Professional manufacturer

Standard workshop

Quality Certificate

Excellent customer service

Zhengzhou Rongsheng Import And Export Co., Ltd.

Our company is located in Henan, China. Our company has professional scientific and technical personnel and production team, and we have our own fully automated factories. For more than ten years, we have focused on the development and innovation of refractory materials and high-temperature furnace technology, and strive to provide customers with comprehensive, personalized and cost-effective services with high-quality products. Our products are widely used in electric power, metallurgy, petrochemical and other fields, and are exported to more than 70 countries and regions in the world such as Europe, America, Oceania, Southeast Asia, and the Middle East.

Zhengzhou Rongsheng Import And Export Co., Ltd.

is a first-class supplier of refractory materials, we can provide you with the most advantageous

quotations and products. Looking forward to be your partner!

FAQ

Q1.

Are you Manufacturer?

A:

Yes, of course, our factory is in Xinmi, zhengzhou city, Henan province.

Q2.

Can we visit your company?

A:

Sure,welcome at any time, seeing is believing.

Q3.

Do you accept OEM?

A:

Yes, we can do OEM.

Q4.

What's the MOQ of trial order?

A:

No limit, we can offer the best suggestions and solutions according to your condition.

Q5.

What are the payment terms?

A:

Usually T/T, but L/C, Western Union etc are available for us.

Q6.

How long is delivery time?

A:

The delivery time usually depends on the order quantity, usually around 7-12 days.

Q7.

How are your products' quality?

A:

The products will be strictly inspected before shipment, so the quality could be guaranteed.

Q8.

How to solve the quality problems?

A:

If the products are not confirmed to customer samples or have quality problems, our company will be responsible to make compensation for it.

Q9.

What is the service life of your bricks?

A:

The service life of different bricks is unlike.It also depends on your using condition and method.

Q10.

How about your company's certification?

A:

ISO9001 and Test Report,also we could apply other necessary certification.

Recommend Products

Hot Searches