- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

450ML

-

Mould material:

-

DC53/SKD11/Cr12mov Etc.

-

Mould Life:

-

5years

-

Mould base:

-

European Standard

-

MOQ:

-

1 Set

-

Delivery Time:

-

45-60days

-

Advantage:

-

Professional Team

-

Mould Cavity:

-

Cusomized

-

Hardness:

-

HRC58-62

-

Surface treatment:

-

Heat Treatment

-

Design:

-

Customer's Reqestment

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ZHULI

-

Model Number:

-

450ML

-

Mould material:

-

DC53/SKD11/Cr12mov Etc.

-

Mould Life:

-

5years

-

Mould base:

-

European Standard

-

MOQ:

-

1 Set

-

Delivery Time:

-

45-60days

-

Advantage:

-

Professional Team

-

Mould Cavity:

-

Cusomized

-

Hardness:

-

HRC58-62

-

Surface treatment:

-

Heat Treatment

-

Design:

-

Customer's Reqestment

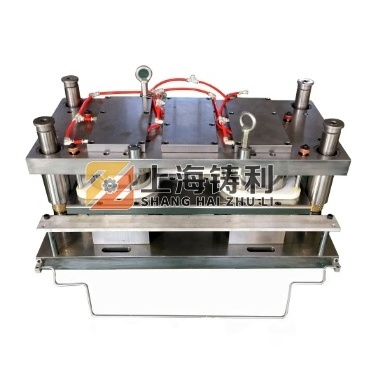

New design aluminum foil container mould 450ML from Shanghai ZHULI

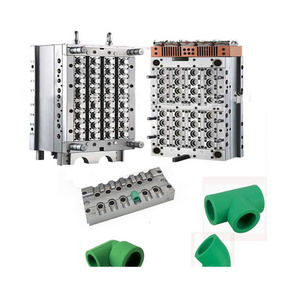

Based on Customer's samples or drawings, we can customize aluminium foil container moulds upon request.The moulds we can design and produce are as follows:

1. No. of cavities: 1, 2, 3, 4,5 cavities or more.

2. Types: wrinkled-wall containers,folded wall containers, aluminium foil container lids.

3. Container shapes: square, rectangular, circular, oval, special shapes etc.

4. Rim styles:we design and manufacture the mold in several rims,such as G rims,L rims etc.

5. We can print your preferred logos upon request.

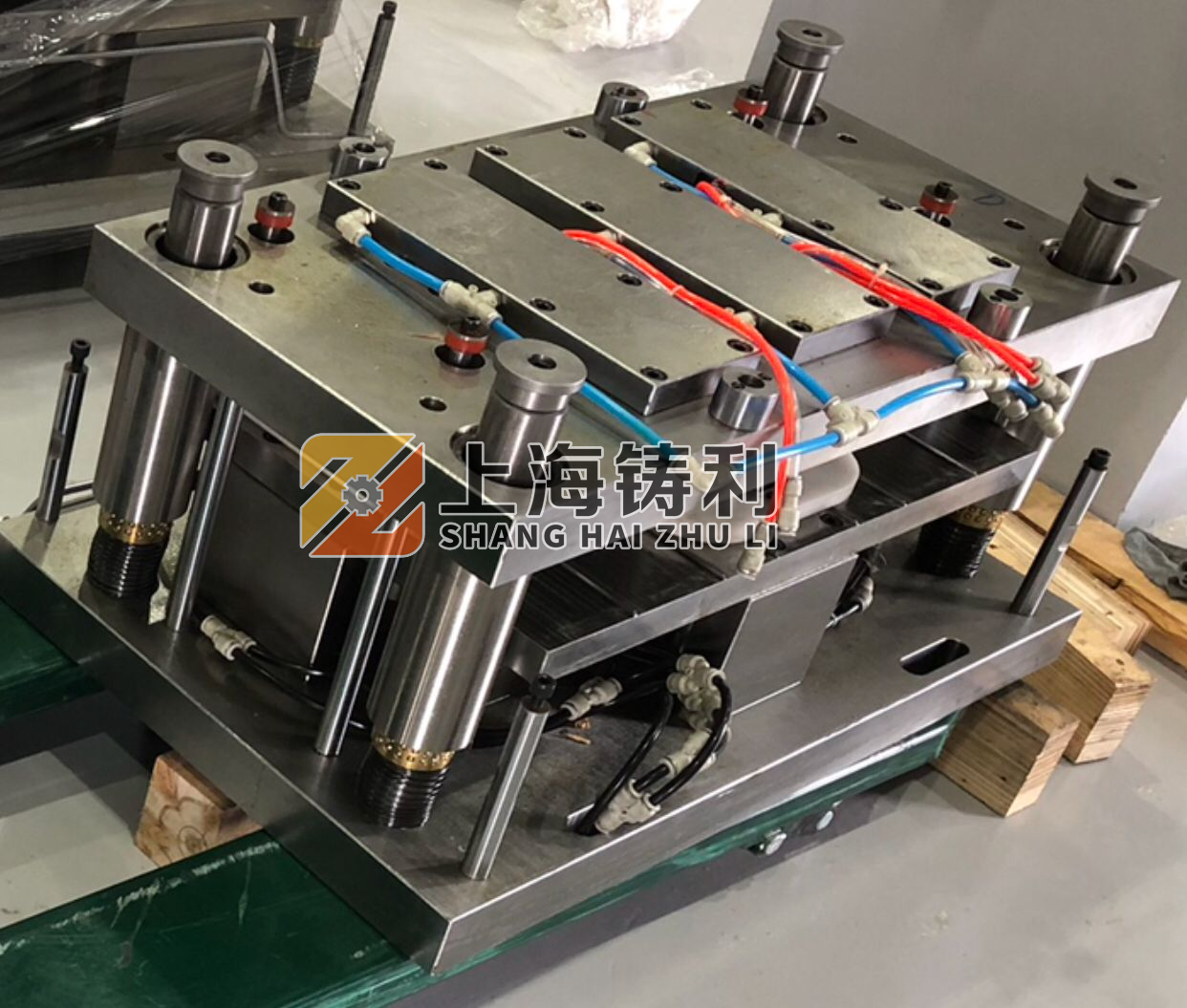

Our mold advantages:

1.Moulds are built with high quality steel.Flow area is heat treated for proper hardness,which ensure our mould in long life.

2.Moulds adopts pneumatic rebound device which makes the mould more flexible.

3.Our excellent processing technical ensure that the mould can complete the cutting, shaping, blanding and curing by one step.

4.The moulds that we design and produce are suitable for almost every kinds of machine.

5.We produce mould with the best quality steel. And some main mould areas are made high-temperature head treatment for proper hardness,which ensure moulds are in great quality.

6.Our die design is scientific and reasonable, ensuring that the scrap rate of the die is less than 15%.

7.Each of our moulds has a fully automatic blowing device,which can ensure stable and efficient production.

Mould processing equipment:

Mold packing:

In the packaging process, we first clean every corner of the die, then spray appropriate protective paint, and then fix the die with pins to ensure that the center of the die will not deviate during transportation. Finally, the mould is wrapped with protective film and packed into the sea wooden box.