- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

depends on model

-

Weight:

-

750 KG

-

Marketing Type:

-

New Product

-

Maxi feeding size:

-

2mm

-

processing capacity:

-

0.5-2T/H

-

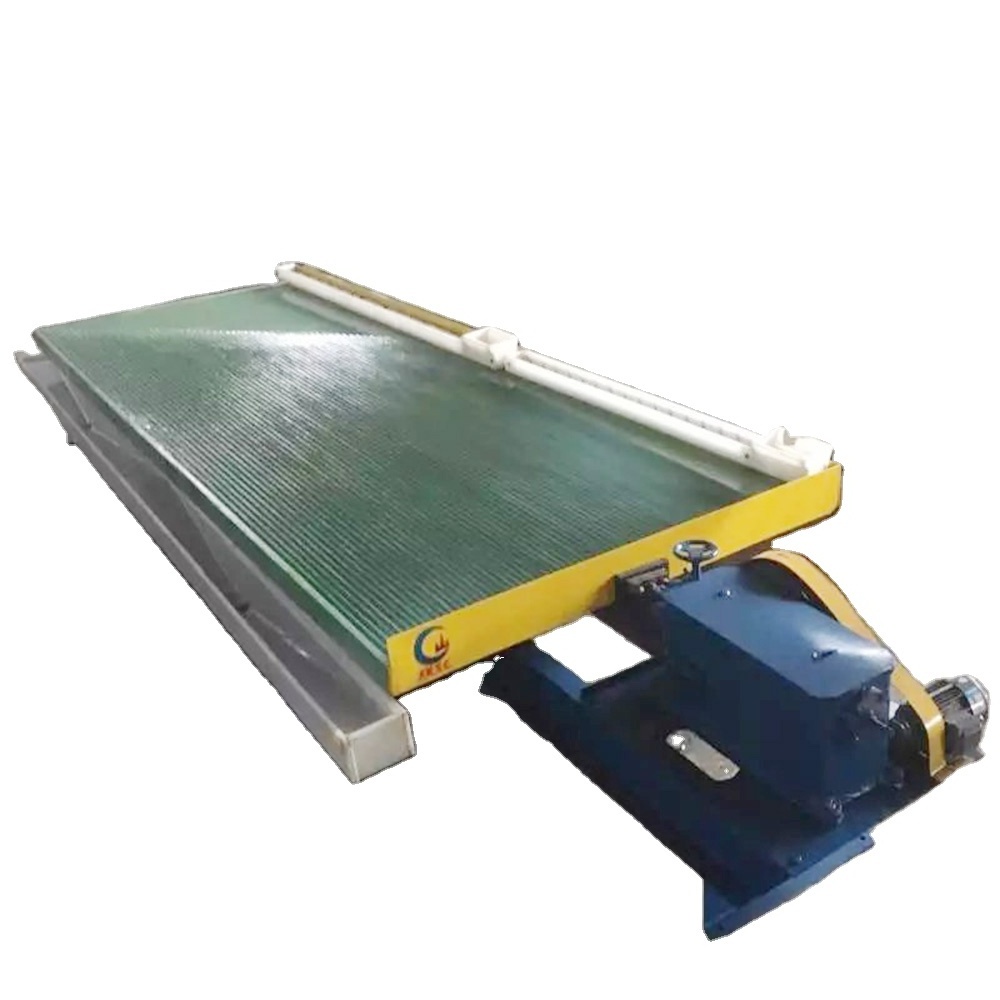

desk size:

-

4500*1850mm

-

desk material:

-

glass fiber reinforced plastics with emery

-

feeding density:

-

10-30%

-

Shaking Table stroke:

-

8-36mm

-

Shaking Table application:

-

for gold/tin/tungsten/coltan/chrome ore concentration

-

Shaking Table table type:

-

fine desk/slime desk/corase desk

-

Shaking Table motor:

-

380v/50hz/3phase

-

Shaking Table:

-

for minerals concentration

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

depends on model

-

Weight:

-

750 KG

-

Marketing Type:

-

New Product

-

Maxi feeding size:

-

2mm

-

processing capacity:

-

0.5-2T/H

-

desk size:

-

4500*1850mm

-

desk material:

-

glass fiber reinforced plastics with emery

-

feeding density:

-

10-30%

-

Shaking Table stroke:

-

8-36mm

-

Shaking Table application:

-

for gold/tin/tungsten/coltan/chrome ore concentration

-

Shaking Table table type:

-

fine desk/slime desk/corase desk

-

Shaking Table motor:

-

380v/50hz/3phase

-

Shaking Table:

-

for minerals concentration

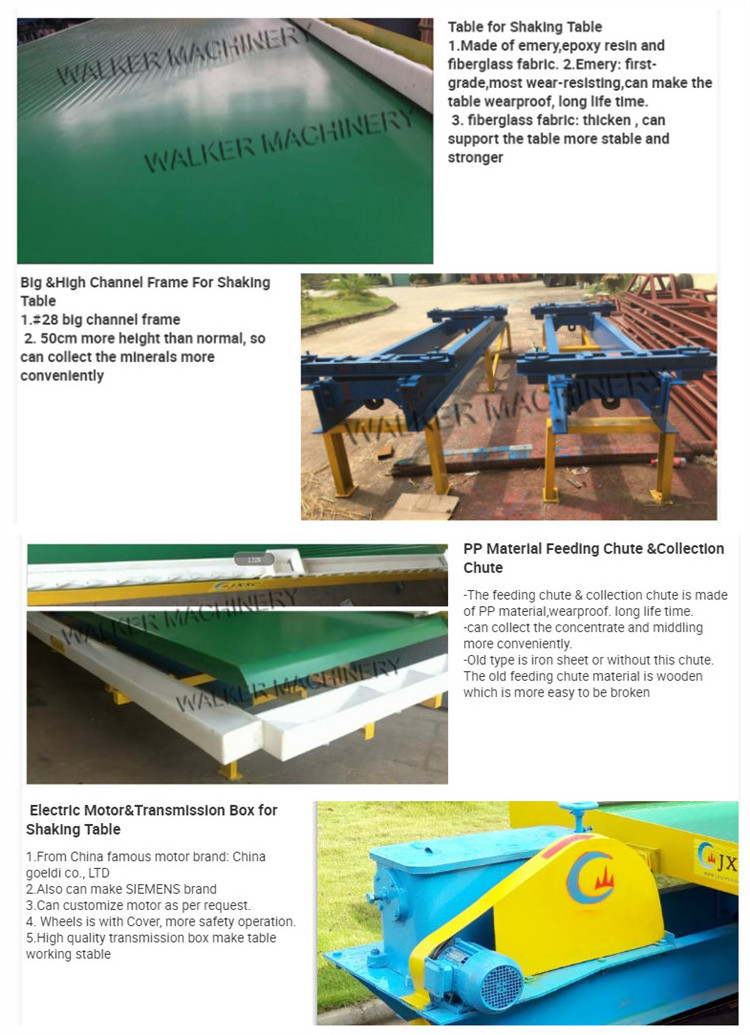

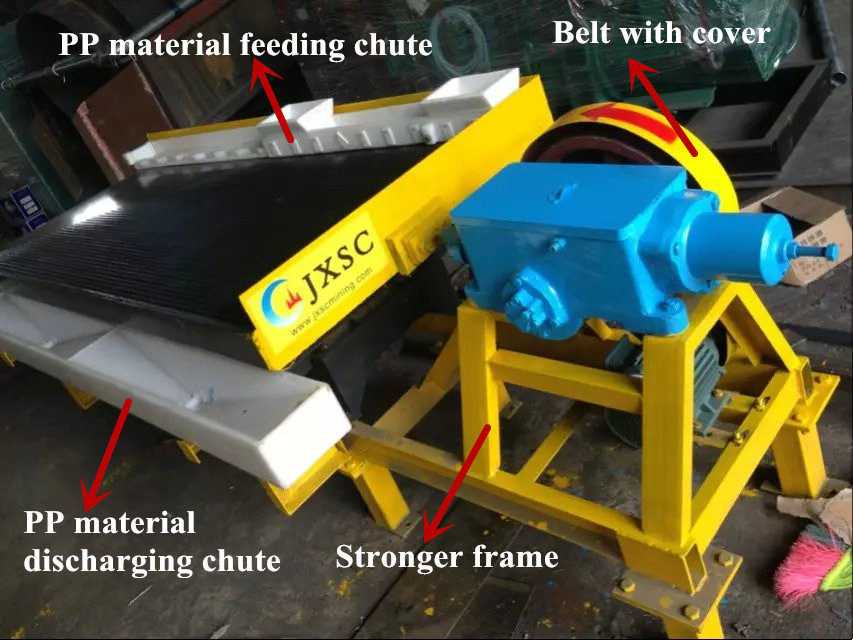

Description of JXSC Shaking Table Separation:

Working principle of Shaking Table Separation:

The working principle of Cobalt Shaker Table is separate the heavy material from light material by using their different proportion & specific gravity, under the effect of gravity, the minerals will divide into the ore concentrate, the middling and the tailing.

The prominent advantage of ore shaking table is precise separation.

The enrichment ratio of concentrate is very good, up to 95% high recovery ratio for kinds of heavy minerals, when dealing with low grade tungsten ore and tin ore, the enrichment ratio could reach about 300 times.

We can get some final concentrates, final tailings and 1 or 2 kinds of middling products after first separating from the feeding mineral.

Shaking Table Features

|

Deck type

|

|

|

|

|

Slime Deck

|

Three different kinds of decks are available

|

|

|

||||

|

Beneficiation Area

|

|

m2

|

7.6

|

7.6

|

7.6

|

4.08

|

1.95

|

0.5

|

||||

|

Deck Size

|

Length

Size

|

mm

|

4450

|

4450

|

4450

|

3000

|

2100

|

1100

|

||||

|

transmission end width

|

|

mm

|

1855

|

1855

|

1855

|

1320

|

1050

|

500

|

||||

|

Concentrate end width

|

|

mm

|

1546

|

1546

|

1546

|

1100

|

850

|

430

|

||||

|

Maximum Feeding Size

|

|

mm

|

2

|

0.5

|

0.15

|

0.1-2

|

0.074-2

|

0.074-2

|

||||

|

Feeding Amount

|

|

t/d

|

30-60

|

10-20

|

15-25

|

0.4-1.5t/h

|

0.3-0.8t/h

|

0.05-0.2t/h

|

||||

|

Feeding Density

|

|

%

|

25-30

|

20-25

|

15-25

|

10-30

|

|

|

||||

|

Stroke

|

|

mm

|

16-22

|

11-16

|

8-16

|

6-30

|

12-28

|

9-17

|

||||

|

Frequency

|

|

f

|

45-48

|

18-53

|

50-57

|

210-320

|

250-450

|

280-460

|

||||

|

Water added

|

|

t/d

|

80-150

|

30-60

|

10-17

|

0.3-1.5t/h

|

0.2-1t/h

|

0.1-0.5t/h

|

||||

|

Transverse slope of Deck

|

|

°

|

2°30-4°30

|

1° 30-3° 30

|

1° -2°

|

0 -10°

|

0 -8°

|

0 -10°

|

||||

|

Longitudinal slope of Deck

|

|

°

|

1.4

|

0.92

|

------

|

------

|

------

|

------

|

||||

|

Cross-section Shape of Deck

|

|

|

rectangular

|

saw tooth

|

triangle

|

Avaliable rectangular, saw tooth, triangle

|

|

|

||||

|

Motor Power

|

|

KW

|

1.1

|

1.1

|

1.1

|

1.1

|

1.1

|

1.1

|

||||

Placer Ore Processing Case in Ghana

Date: 2017Place: Russia Federation

Mineral: Chrome

Maximum Feeding Size: 0-2mm

Order quantities: 20sets

Other machines:hopper,trommel screen, mixing tank, sluice box, smelting furnace, etc.

Date: 2019Mine site: Uganda

Processing mineral: Coltan ore

Full set equipment for entire line:Trommel scrubber>Vibration screen>Jig machine>Shaking table

Customer's feedback: Coltan recovery reached 90%, customer was happy with our equipment.

This Plant also can be used for Hard Rock Tin ore/ Coltan ore/ Tungsten Ore/ Chrome Ore

primary processing.Process flowchart as below: Jaw crusher-> belt conveyor-> hammer crusher-> shaking table

Main machines specifications :

1- Jaw crusher: 2 sets (one set for reserve), model PE150*250. with 1-3 TPH capacity, flywheel with cover, with diesel engine.

2.-Belt Conveyor: 1 set, 10 m long, 500 mm width.

3.-Hammer crusher: 1 set, model PC400*300, 1-3 TPH capacity, 0-2 mm output size. flywheel with cover, with diesel engine, with strong frame operation floor, wet process.

4.-Shaking table: 2 sets, model 6S big shaking table, with 1 TPH capacity, table size 4500*1850mm. New

Packing/Loading

2. 6s Shaking Tables are fixed and loaded in container.

Shipping

2. 6s Shaking Table can be also shipped by air if customers request.

Jiangxi walker Machinery Co.,Ltd, is a professional manufacturer of complete set mining equipments, a sub-company of JXSC mine machinery factory in Jiangxi province. professional at providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set small lab mining machines.

Our Core Advantages as below :

1.+30 years history FACTORY at mining machinery

2.Provide engineer team after sales service

3.Provide Complete set mineral processing plant

4.Provide Sample testing service in factory lab for free

5.Provide professional Mining Solution Consulting

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.Guaranteed:

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Our service

Pre-sales service : We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

Sales service:

Send technicians to the jobsite guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sales service: To establish long term friendship, we will reg-ularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

Lifelong service:

One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

Very good service help us win many clients from all over the world.