- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CNMC

-

Model Number:

-

polyurethane rigid foam

-

Type:

-

Polyurethane

-

DJD-105 blend polyols:

-

100pbw

-

Isocyanate:

-

100-105pbw

-

Product name:

-

Chemicals PU Material isocyanateand blend polyols

-

Appearance:

-

Pale yellow to brown viscous liquid

-

Hydroxyl Value:

-

200-300mgKOH/g

-

Dynamic Viscosity(25degree centigrade ):

-

100-200mpa.s

-

Specific gravity(20degree centigrade):

-

1.12-1.20g/ml

-

Storage Temperature:

-

10-25degree centigrade

-

Cream Time:

-

3-5s

-

Gel time:

-

6-10s

Quick Details

-

CAS No.:

-

9003-11-6

-

Other Names:

-

Polyurethane Rigid Foam

-

MF:

-

C3H8N2O

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CNMC

-

Model Number:

-

polyurethane rigid foam

-

Type:

-

Polyurethane

-

DJD-105 blend polyols:

-

100pbw

-

Isocyanate:

-

100-105pbw

-

Product name:

-

Chemicals PU Material isocyanateand blend polyols

-

Appearance:

-

Pale yellow to brown viscous liquid

-

Hydroxyl Value:

-

200-300mgKOH/g

-

Dynamic Viscosity(25degree centigrade ):

-

100-200mpa.s

-

Specific gravity(20degree centigrade):

-

1.12-1.20g/ml

-

Storage Temperature:

-

10-25degree centigrade

-

Cream Time:

-

3-5s

-

Gel time:

-

6-10s

Two Component Polyurethane foam Liquid for sale

It is a light yellow liquid at room temperature. It has been developed to produce B1 class fireproof outer wall spraying thermal insulation.The product is a mixture consisting of polyether polyols, silicone stabilizer, flame retardant and catalys.

polyurethane foam polyurea material.

lt is a fully formulated polyol blend developed for spray application of polyurethane rigid foam. The component

ratio of has been adjusted to make it suitable for polyurethane foam spraying machine using with a fixed volumetric component ratio of 1-1.2

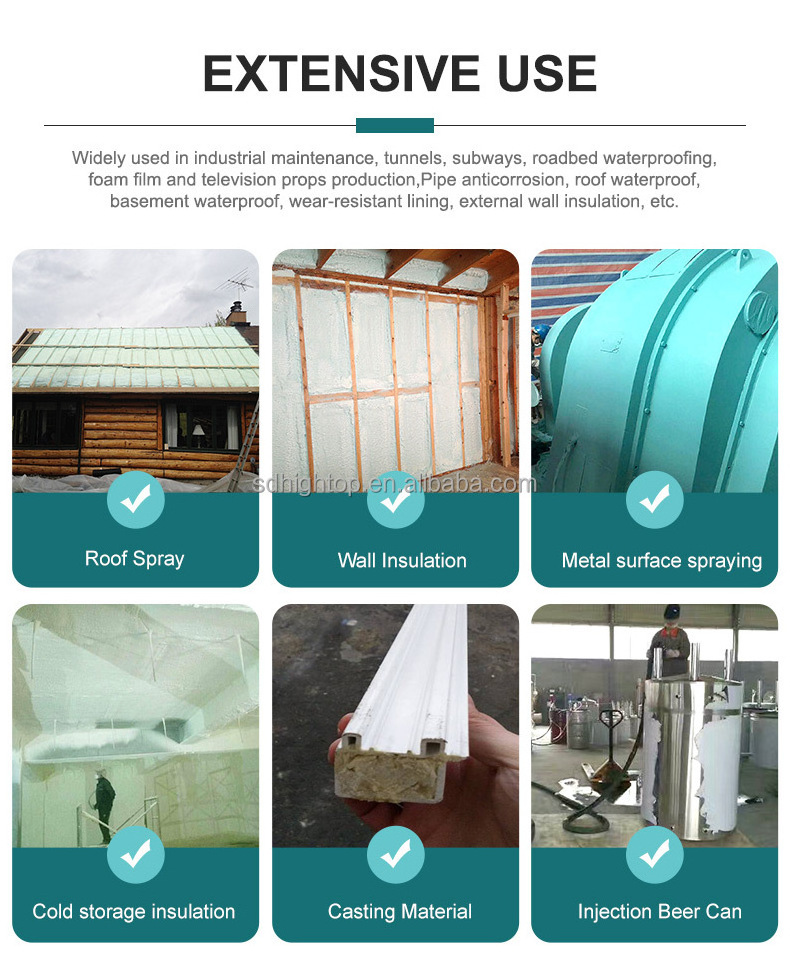

T-501A is spray blend polyols, it reacts with isocyanate to produce foam which has excellent performances, which are as follows,

1. polyurethane foam polyurea material.1.High closed-cell rate, good water-proof

2.Good thermal insulation

3.High compressive strength

24-HOUR ONLINE SERVICE:

Elva Liu:Wechat/Skype/Whatsapp: +8618653793310

Email:sales20@sdchinamachine.com

|

CLOSED CELL POLYURENE MDI &POLY PHYSICAL PROPERTIES

|

|

|

|

|||

|

1

|

Density

|

245FA/ft²

|

33.6kg/³

|

|||

|

2

|

Initial Thermal Resistance (R-value@ 1 inch )See ESR for additional R-Value information

|

7.4ft²hF/BTU

|

1.3Km²/w

|

|||

|

3

|

Air Leakage @75Pa@1”

|

<0.002L/sm²

|

|

|||

|

4

|

Air Permeance @75 Pa@1”

|

<0.002L/sm²

|

|

|||

|

5

|

System Air Leakage Rating ,After wind Conditioning @ ∆

|

<0.0022L/sm²

|

|

|||

|

6

|

Penetrations Check :Continuity at Penetrations @ reference air leakage

|

Pass

|

|

|||

|

7

|

Water vapor Permeance @1.42”

Qualifies as a Class II vapor barrier per IBC Section 202 |

<1perm

|

<57.2ng/Pa•s•m

|

|||

|

8

|

Compressive Strength

|

28.7Psi

|

198kPa

|

|||

|

9

|

Tensile Strength

|

46.2Psi

|

319Kpa

|

|||

|

10

|

Dimensional Stability @158°F(70°C)97% R.H

(168 hrs,sample without any substrate) |

(% volume change )

-1.37/-0.42/+0.27 |

|

|||

|

11

|

VOC Emissions Standard

|

Complaint

|

|

|||

|

12

|

Closed Cell Content

|

≥90%

|

|

|||

Wood Imitation Rigid Polyurethane Blend Polyols

simple molding process, high production efficiency and excellent appearance. Characteristics are as follows, 1.Excellent repetition molding property. It not only can mould certain shape size, but also mould lifelike wood texture and other designs, good touch.

|

Appearance

|

Light yellow to brown yellow viscous liquid

|

|

OHvalue mgKOH/g

|

250-400

|

|

Dynamic viscosity (25℃) mPa.S

|

1000-1500

|

|

Density (20℃) g/ml

|

1.10±0.02

|

|

Storage temperature ℃

|

10-25

|

|

Storage stability month

|

6

|

|

Raw materials

|

pbw

|

|

DonFoam 601 polyols

|

100 g

|

|

Powder

|

3-5

|

|

Isocyanate

|

60-100

|

|

Rise time

|

50-70s

|

|

Gel time

|

140-160s

|

|

Tack free time

|

200-220s

|

|

Free density

|

300-850kg/m3

|

|

Moulding density

|

400-1000 kg/m3

|

|

Curving strength

|

7-20 MPa

|

|

Compressive strength

|

7-30 MPa

|

|

Tensile strength

|

5-20 MPa

|

|

Surface strength

|

35-70 (Shore D)

|

|

Shrinking ratio

|

≤0.1%

|

Elva Liu:Wechat/Skype/Whatsapp: +8618653793310

Email:sales20@sdchinamachine.com