By using a vacuum cup and a gripper, the insert is pushed precisely into the carton. The machine stops when there is no insert so as to avoid product missing with insert.

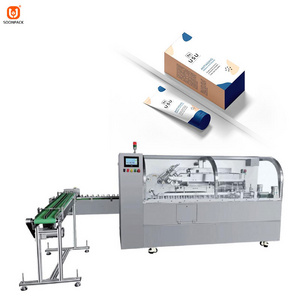

The Horizontal Intermittent Motion Cartoner is specifically designed for small batch production.

This machine is suitable for use in pharmaceutical, cosmetic, food and consumer products industries.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

L3409*W1403*H1830mm

-

Weight:

-

1200 KG

-

Product name:

-

horizontal cartoner machine

-

Model:

-

CX-Z100

-

Case size range:

-

L90-350*W50-190*H20-80mm

-

efficiency:

-

30-60cases/min

-

Gas consumption:

-

120-160NL/Min

-

box sealing type:

-

insert or gluing

-

machine size:

-

L3409*W1403*H1830mm

-

machine weight:

-

1200kg

-

air pressure:

-

0.2-0.4Mpa

-

Machine type:

-

fully automatic

Quick Details

-

Application:

-

Food, Beverage, Chemical, Cigarettes

-

Packaging Material:

-

Paper

-

Voltage:

-

220-480V 3Phase

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

L3409*W1403*H1830mm

-

Weight:

-

1200 KG

-

Product name:

-

horizontal cartoner machine

-

Model:

-

CX-Z100

-

Case size range:

-

L90-350*W50-190*H20-80mm

-

efficiency:

-

30-60cases/min

-

Gas consumption:

-

120-160NL/Min

-

box sealing type:

-

insert or gluing

-

machine size:

-

L3409*W1403*H1830mm

-

machine weight:

-

1200kg

-

air pressure:

-

0.2-0.4Mpa

-

Machine type:

-

fully automatic

Product Description

This horizontal automatic glue cartoning machine completes product insertion in one run and close all sides or plus hot melt glue sealing. Also equipped are malfunction warnings for fail safe packaging processes. It is labor saving, suitable for pharmaceutical, ointment or cream tubes, cosmetics, hardwares, stationary, etc.t

his machine is also compatible with two functions: hot melt sealing and only closing the box flaps. When hot melt sealing is not needed, the hot melt sytem can be turned off, and then the machine only closes the box.On the contrary, if needed, turning on the hot melt machine will seal the hot melt.

Product insert to case box

Specification

|

Product

|

Horizontal Cartoning Machine

|

|

Model

|

CX-Z100

|

|

Hot melt glue system

|

Chinese brand or Nordson or Robatech brand

|

|

Control sysem

|

PLC

|

|

Control panel

|

HMI/Touch screen

|

|

Application filed

|

Pharmaceutical, ointment or cream tubes, cosmetics, hardwares, stationary

|

|

Case size range

|

L90-350*W50-190*H20-80mm(other sizes customized)

|

|

Suitable for box

|

locked bottom box, flaps insert box or hot melt gluing box

|

|

Air pressure

|

0.2-0.4Mpa

|

|

Gas consumption

|

120-160NL/min

|

|

Machine efficiency

|

30-60cases/min

|

|

Volts

|

220-380V 3Phase 50-60Hz 1.5kw

|

|

Machine size

|

L4150*W1421*H1688mm

|

|

Machine weight

|

1000kg

|

|

Optional

|

Automatic feeding conveyor, date/batch number printer

|

Details Images

Touch screen of control panel, English language,easy to set parameters.

Famous brand of PLC, Inveter control system, machine running more stable.

Hot melt glue system

The box storager is lengthened to reduce the frequency of filling the box to improve production efficiency.

The product conveying is stable, and the mold width is adjusted according to the product width.

The electronic eye automatically detects the product, and then transmits the signal to the PLC to forming the carton. (if the

photoelectric sensor detects that there is no product, the carton forming instruction will not be carried out)

photoelectric sensor detects that there is no product, the carton forming instruction will not be carried out)

Machine adjustable as different box height, digital display, easy to adjust.

The pushing arm adjustable.we also can free provide extra 1pcs according to your minimum product size.then you can replace it by yourself after released the screw.

Machine adjustable according to different box wide.adjust it by side handwheel.

Product packaging

Recommend Products

Hot Searches