The bolt tray is an important part of the bolt support system, and its performance directly affects the support effect of the bolt. The function of the pallet is to transmit the thrust generated by the locking torque of the nut to the top help, generate the initial anchor force, and at the same time transmit the pressure of the roadway top help to the bolt, generate working resistance, strengthen the surrounding rock together, and prevent the roadway top help from breaking down. displacement. Our company can provide a complete production line of bolt pallets, including hydraulic presses, molds, and automatic feeding devices.

- Product Details

- {{item.text}}

Quick Details

-

Return Force (kN):

-

5000 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Weili Heavy Industry

-

Voltage:

-

any

-

Dimension(L*W*H):

-

3880x1700x4350

-

Weight (T):

-

18 T

-

Model Number:

-

YW32-500T

-

Motor Power (kw):

-

30 kw

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Can be free to choose

-

Work table size:

-

Can be free to choose

-

The machine body:

-

Steel plate welded and seamless

-

Machine type:

-

Three beam four column hydraulic machine

-

Feature:

-

Simple structure ,especially

-

Function:

-

Punching and press

-

Structure:

-

Three beam four column

-

Painting process:

-

Stoving varnish or spraying plastics

-

Drive:

-

Hydraulic

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Slide Stroke (mm):

-

600

-

Ejector Force (kN):

-

0

-

Return Force (kN):

-

5000 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Weili Heavy Industry

-

Voltage:

-

any

-

Dimension(L*W*H):

-

3880x1700x4350

-

Weight (T):

-

18 T

-

Model Number:

-

YW32-500T

-

Motor Power (kw):

-

30 kw

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Can be free to choose

-

Work table size:

-

Can be free to choose

-

The machine body:

-

Steel plate welded and seamless

-

Machine type:

-

Three beam four column hydraulic machine

-

Feature:

-

Simple structure ,especially

-

Function:

-

Punching and press

-

Structure:

-

Three beam four column

-

Painting process:

-

Stoving varnish or spraying plastics

-

Drive:

-

Hydraulic

Products Description

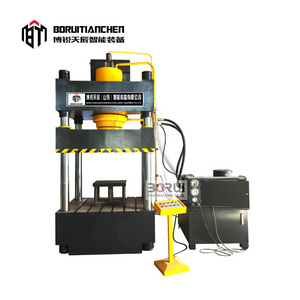

Anchor rod tray hydraulic press machine

Produce feature

1. Computer optimized structure design, three-beam four-post structure, simple, economical and practical.

2. Hydraulic control cartridge valve integrated system reliability, long life and small hydraulic impact, reducing the link pipe

and leak points.

3. Independent electrical control system working reliably. Action and intuitive. Easy maintenance.

4. Use the button centralized control, with adjustment for manual and semiautomatic operation.

5. Via the operator panel to choose from. Can be achieved given away two constant pressure forming process, and has features such as security during rolling.

6. Slider working pressure load and slow down quickly work into the travel range can be adjusted according to process

requirements.

2. Hydraulic control cartridge valve integrated system reliability, long life and small hydraulic impact, reducing the link pipe

and leak points.

3. Independent electrical control system working reliably. Action and intuitive. Easy maintenance.

4. Use the button centralized control, with adjustment for manual and semiautomatic operation.

5. Via the operator panel to choose from. Can be achieved given away two constant pressure forming process, and has features such as security during rolling.

6. Slider working pressure load and slow down quickly work into the travel range can be adjusted according to process

requirements.

Structural features

1.Hydraulic press is composed of main machine, hydraulic transmission system, electrical control system and lubrication system.

2.There are three operation modes of hydraulic press: manual operation, point operation and semi-automatic switching control. The operation mode is selected by the switch and the button is centralized controlled.

3.The fuselage is a three-beam and four-column structure, the slider is guided by the cylinder surface of the column, the guide sleeve is guided by the guide sleeve to facilitate maintenance, and the column is a four-Nut structure.

4.The slider of hydraulic press is a single cylinder pressurized structure with upper transmission.

5.The main control system of hydraulic system adopts two-way cartridge valve integrated system.

6.The main oil pump of hydraulic system adopts YCY14-1B constant power axial piston pump.

7.The main cylinder of slide block adopts piston type cylinder, and the cylinder seal adopts original imported U-ring seal.

8.Hydraulic power system, electrical cabinet, operation button box placed in the right end of the machine.

9.Proximity switch control is adopted in the stroke control of hydraulic press slider and ejection cylinder.

2.There are three operation modes of hydraulic press: manual operation, point operation and semi-automatic switching control. The operation mode is selected by the switch and the button is centralized controlled.

3.The fuselage is a three-beam and four-column structure, the slider is guided by the cylinder surface of the column, the guide sleeve is guided by the guide sleeve to facilitate maintenance, and the column is a four-Nut structure.

4.The slider of hydraulic press is a single cylinder pressurized structure with upper transmission.

5.The main control system of hydraulic system adopts two-way cartridge valve integrated system.

6.The main oil pump of hydraulic system adopts YCY14-1B constant power axial piston pump.

7.The main cylinder of slide block adopts piston type cylinder, and the cylinder seal adopts original imported U-ring seal.

8.Hydraulic power system, electrical cabinet, operation button box placed in the right end of the machine.

9.Proximity switch control is adopted in the stroke control of hydraulic press slider and ejection cylinder.

Automatic feeding

Feeder:

1.The production of anchor cable tray adopts long plate servo automatic feeding, one-time cutting and pressing, which greatly improves the production efficiency, reduces the labor intensity of employees, and ensures safe production compared with the use of plate shears to cut into a single re pressing.

2.According to the product specifications, the integrated cutting and pressing molds shall be customized. One mold can only produce one product.

3.The longer the raw materials are, the better the advantages of automatic feeding can be reflected. Due to the transportation, the floor area of the machine tool and other reasons, it is appropriate to select a length of six meters. The plates should be straight, free of burrs and can not be distorted. It is suggested to use multi head straight flame cutting machine to produce raw materials. The length of raw materials should be basically the same, and both ends should be flush with each other, so as to reduce the joint gap. The advantages of multi head straight flame cutting machine are small deformation and lengthening. It is not recommended to use the plate shears to produce raw materials. The disadvantage is that the length of the plate shears is short, and the sheared materials will be distorted and cannot be fed automatically.

4. Due to the relatively short raw materials and frequent feeding, the key is to properly handle the last material head. When the last anchor cable tray is left, adjust the numerical control feeder to manual mode, operate the mobile electronic handwheel to use the rear strip material, and push the last anchor cable tray into the mold for pressing only. It should be noted that after the long plate material pushes the last anchor cable tray into the cross tool, it should be slightly returned to the knife edge. After the last piece is pressed and formed, operate the hand wheel to align the long material with the tool edge of the mold, and then start the automatic program to work continuously and realize automatic.

5.

The CNC feeder is easy to operate and can adapt to different specifications of anchor cable trays. When changing the model, it is only necessary to change the feeding length and the number of shears of each long sheet in the program.

Product Paramenters

|

Specification

|

Unit

|

YW32-500T

|

YW32-630T

|

|

Nominal pressure

|

kN

|

5000

|

6300

|

|

Liquid maximum working pressure

|

Mpa

|

31.5

|

31.5

|

|

The maximum travel oil cylinder

|

mm

|

600

|

600

|

|

The largest open

|

mm

|

800

|

800

|

|

Worktable size

|

mm

|

1000x1000

|

1000x1000

|

|

Fast forward speed

|

mm/s

|

120

|

120

|

|

Work into the speed

|

mm/s

|

12-16

|

12-16

|

|

The return rate

|

mm/s

|

70

|

70

|

|

The motor

|

kw

|

2x22

|

59

|

|

Machine size

|

mm

|

3600x1500x3600

|

3600x1500x3600

|

Product and mould pictures

Customer Photos

Product packaging

Hot Searches