- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

10-20

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.15 - 1 mm

-

Heating Power (kW):

-

15 kW

-

Air Comsumption(L/min):

-

1200 L/min

-

Water Comsumption(L/min):

-

10 L/min

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Food container making machine

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3300*1650*2250(mm)

-

Weight (T):

-

2.5 T

-

Power(KW):

-

23

Quick Details

-

Max.Forming Height(mm):

-

100 mm

-

Forming Width (mm):

-

510 mm

-

Forming Length (mm):

-

570 mm

-

Production Speed(Cycles/min):

-

10-20

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.15 - 1 mm

-

Heating Power (kW):

-

15 kW

-

Air Comsumption(L/min):

-

1200 L/min

-

Water Comsumption(L/min):

-

10 L/min

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Food container making machine

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3300*1650*2250(mm)

-

Weight (T):

-

2.5 T

-

Power(KW):

-

23

PLASTIC PP PS PE PET FOOD CONTAINER MAKING MACHINE

1. Introduction of food tray making machine:

HSC-660C thermoforming machine is a combination of mechanical, electrical and pneumatic components, and the whole system was controlled by micro PLC. It is operates with man-interface, which can works all by itself. It combines the material feeding, heating, drawing, forming, cutting into one process.

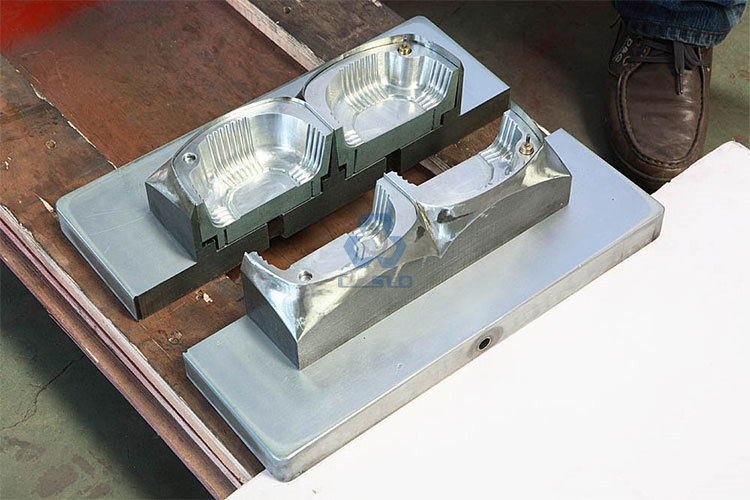

2. Main features of food tray making machine:

It is used for forming PP, PS, HIPS, PVC and PET plastic sheets, which can be widely used to produce all kinds of plastic boxes, containers and other plastic wares, such as ice-cream cups, milk cups chocolate package boxes, candy boxes and fast-food boxes etc.

3. Main technical parameter of food tray making machine:

| 1) Forming area:510*570mm | 2) Forming depth:100mm |

| 3) Sheet thickness range:0.15-1mm | 4) Sheet roller diameter:710mm |

| 5) Cutting length:6350mm | 6) Ari pressure:0.7Mpa |

| 7) Water consumption: Liters/min(15-20 ℃ ) | 8) Air consumption:1200 Liters/min |

| 9) Speed:10-20 mould/min | 10) Power:3-N AC308V±10% |

| 11) Pre heater power:4KW | 12) Mould plate heating power:4KW |

| 13) Heating plate power:10KW | 14) Sheet width: 650mm Max |

| 15) Weight: 3000kg | 16) Dimension(L*W*H): 3000*2000*2150(mm) |

4.

Machine show of food tray making machine:

1. We design, engineer and manufacture and customized the extrusion line.

2. Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

3. Training & Development: we offer extensive start-up assistance, comprehensive training. As well as Engineers for training and installation at our client’s factory

4. Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner.

Our company is established in 1988, specialize in making extrusion equipment, thermoforming equipment and relevant facilities as well as moulds, and it is a limited reliability company which sets development, manufacture, sales and service in one.

We have strong research & development and manufacture ability, and it has a team consisting of professional staff from different engineering fields. Our factory is located in Zhejiang Province of China. We have a team of more than 100 empolyees.

Our machine is with advanced world levels, and its cost performance is incomparable all over the world. The company supplies foaming sheet units, which can produce foaming PE and PS sheet and board. The tandem-foaming machines is mainly making foaming PS sheet and board; Due to various advanced technology, the range foam expansion ratio is very wide and techniques is extremely stable. The single-foaming unit is mainly for PE sheet, and it is simply structured, which is easy for operation with reasonable price.

We are in the lead of thermoforming equipment industry. Its two-station electric thermoforming and trimming unit is set with 6 to 7 servo motors, which can save various kinds of parameters, and have high degree automation and speed. Its forming speed can reach 40 cycles per minute, trimming 160 cycles per minute, and it can process all kinds foaming material and hard

material. One-station thermoforming machine combines forming, punching, and stacking in one machine, which is equipped with 10 to 16 servo motors, and can memorize various kinds of processing parameters. Its forming speed can be 50 cycles per minute. And it can be applied to several kinds of hard material.

Meanwhile, We can provide customer relevant auxiliary parts and moulds, as well as turn-key project service.

Our fast food box production line is completely different to that of other Chinese suppliers. We are using US standard machine.

1. PS foam sheet machine, we have high technology design and ample experiences. For example, we have patent design technology for anti-leakage in the extruder. It's very important and difficult. In all over the world, there are only three companies that hold this technology. We are one of them.

2. For forming and cutting machine, our machine has double capacity to other thermoforming machine: forming frequency--30 times per minute; cutting frequency--2 times per second. It can help you to save at least 50% electricity consumption.

3. We have big market shares in USA, Canada, South America, and other countries.

l Contactor: Mr. Louies Liu

l Skype: louies.cissco

l Cellphone/ Whatsapp/WeChat: +86 18917527205

l Web: www.cisscomachinery.com

l Add: No. 58, New Jinqiao Road, Pudong, Shanghai, China