- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

cable manufacturing line

-

Machine type:

-

cable wire production line

-

Control type:

-

PLC+HMI+Inverter control

-

Twisting section:

-

custom-made

-

single wire diameter:

-

custom-made

-

Twisting pitch(mm):

-

5.76-52.89

-

machine bearing:

-

made in Sweden or Japan

-

Traversing type:

-

Transverse and distance can be bearing transverse

-

Max.bobbin weighe:

-

30kg

Quick Details

-

Use:

-

Stranding

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Pingyang

-

Model Number:

-

cable manufacturing line

-

Machine type:

-

cable wire production line

-

Control type:

-

PLC+HMI+Inverter control

-

Twisting section:

-

custom-made

-

single wire diameter:

-

custom-made

-

Twisting pitch(mm):

-

5.76-52.89

-

machine bearing:

-

made in Sweden or Japan

-

Traversing type:

-

Transverse and distance can be bearing transverse

-

Max.bobbin weighe:

-

30kg

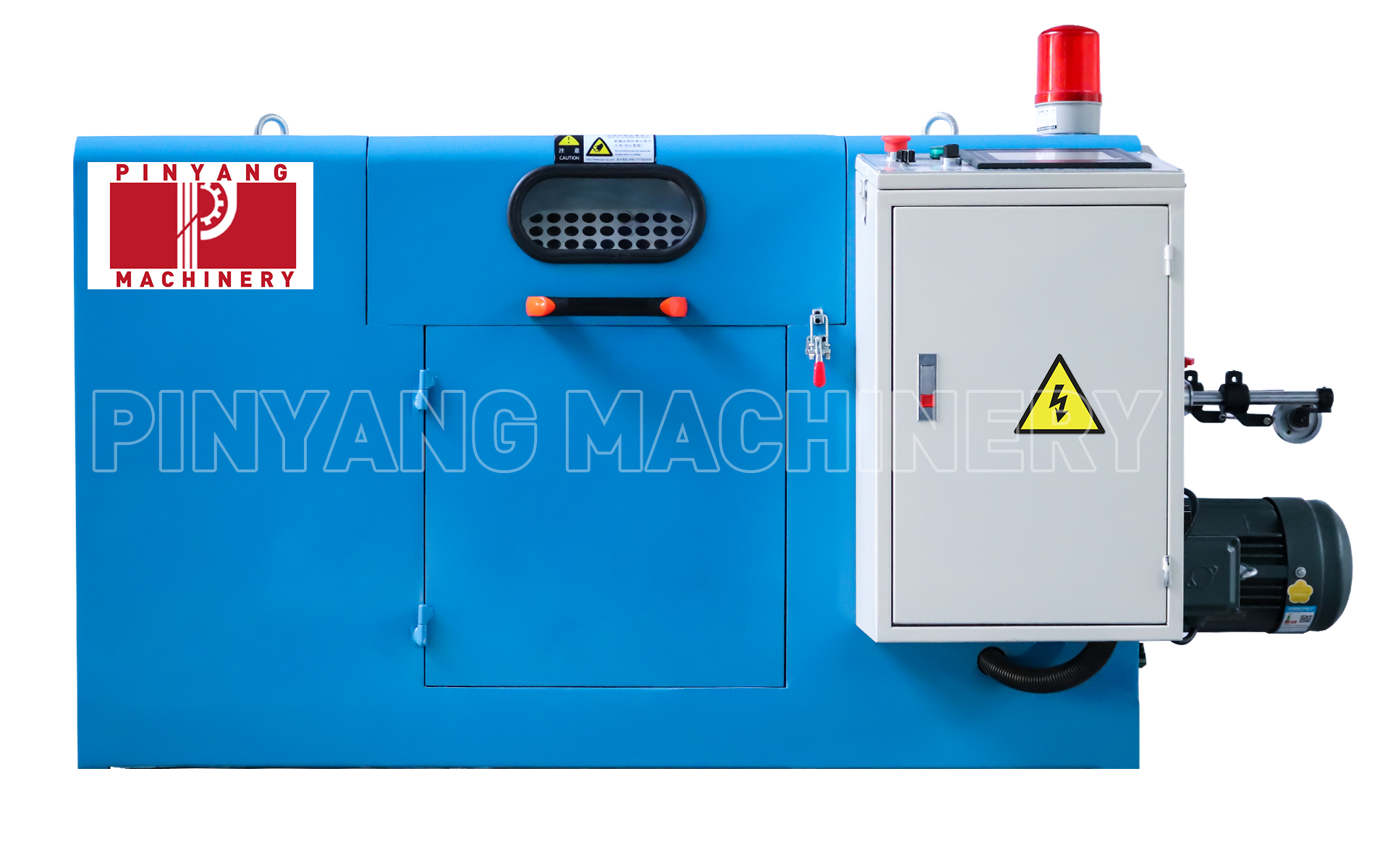

Electronic wire cable production line usb mobile data cable manufacturing machine

|

PY- Φ 300mm PLC High speed bunching machine |

|

|

Inlet wire dia |

0.04-0.28mm |

|

Stranding section area |

0.035-1mm 2 |

|

Lay length |

2.23-34.88mm ( adjustable according to customer requirement ) |

|

Direction of lay |

Operation for right and left |

|

Take up bobbin size |

Φ 300mm |

|

Max rotating speed |

3000RPM/min(6000TPM) |

|

Main motor power |

5HP |

|

Inverter power |

5HP |

|

Tension control method |

Mechanism friction |

|

Protection |

Automatically brake/stop A. Wire inside and outside is broken B. The preset length is arrived |

|

Brake mode |

Electromagnetic brake |

|

Traversing method |

Rolling wire with ring drive units, row pitch and breadth are adjustable |

|

Operation type |

Push button control/Operate on the touch screen |

|

Bobbin lifting |

Manual hydraulic lifting |

Application:

This machine applies to bunch conductor for Earphone wire,Electronic wire,Telephone wire,Automotive wire,Medical instrument,Aerosapace etc.

Suitable conductor:above senven pcs of alloy wires,tinned wires,silver jacketed wire,enamelled wire and other super fine conductors.

Features:

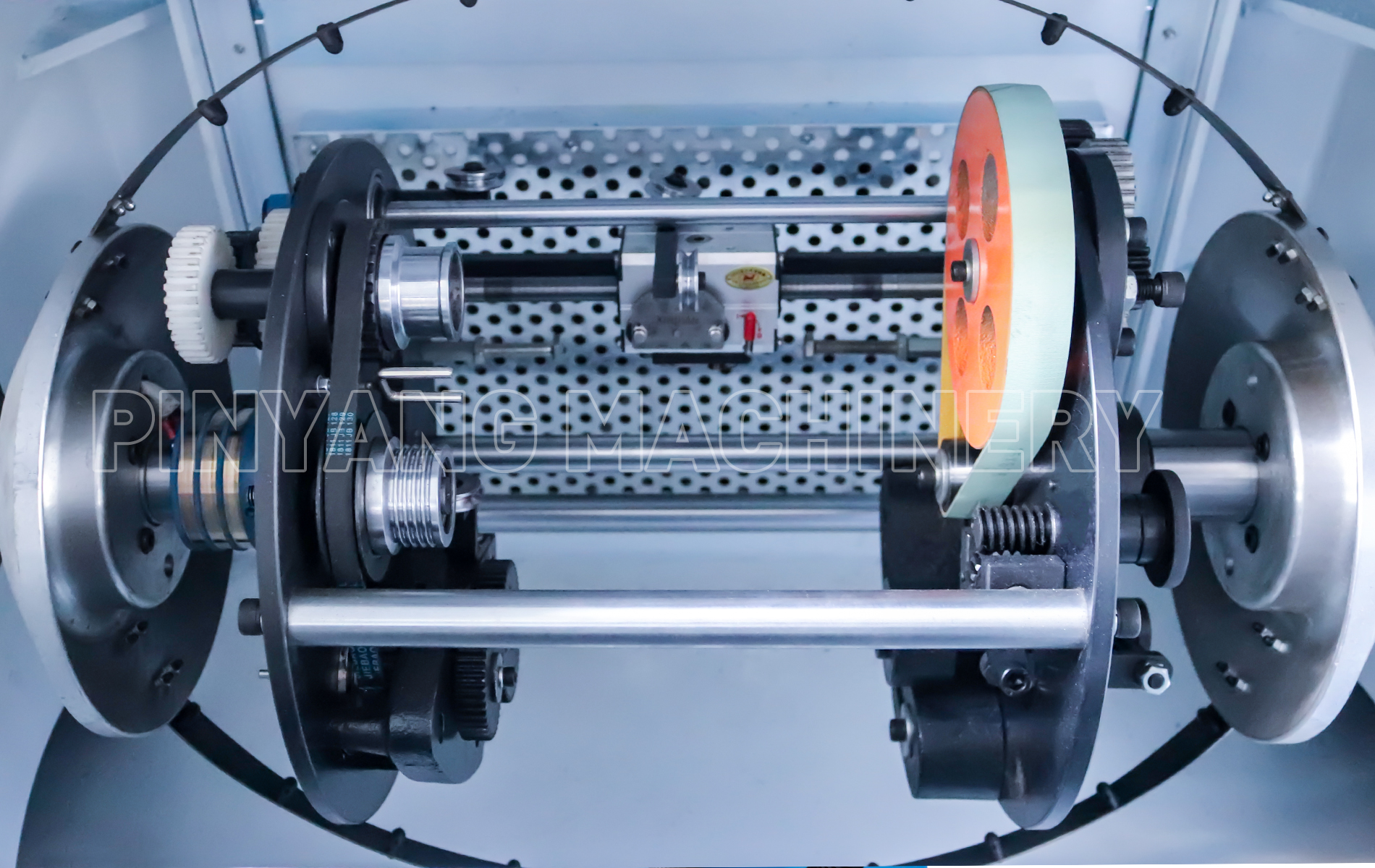

- Stable tension

Constant tension from empty to full bobbin, the machine can automatically track and adjust take up tension, can adjust tension without stopping.

- High quality stranding wire

Th wire-passing system adopts a new structure and the wire directly passed from the main shaft guide wheel to bow band, so the scratching and jumping phenomenon caused by failure of the corner guide wheel on the Al wheel is subtracted.

-Reduce the failure rate and maintenance costs

The main engine is oil lubricated and naturally circulated and cooled, which effectively extends the service life of the main shaft bearings.

The bearings of the whole machine are all well-known Japan brands, The bow belt is made of new materials and has good flexibility. In high-speed operation, it avoids jumping stock caused by vibration. Inverter, magnetic powder clutch, electromagnetic brake, hydraulic jack etc are all imported famous brands.

-Easy to operate

Siemens software, PLC control, Operate on the touch screen, change gear to change lay length.

Techinal specification: