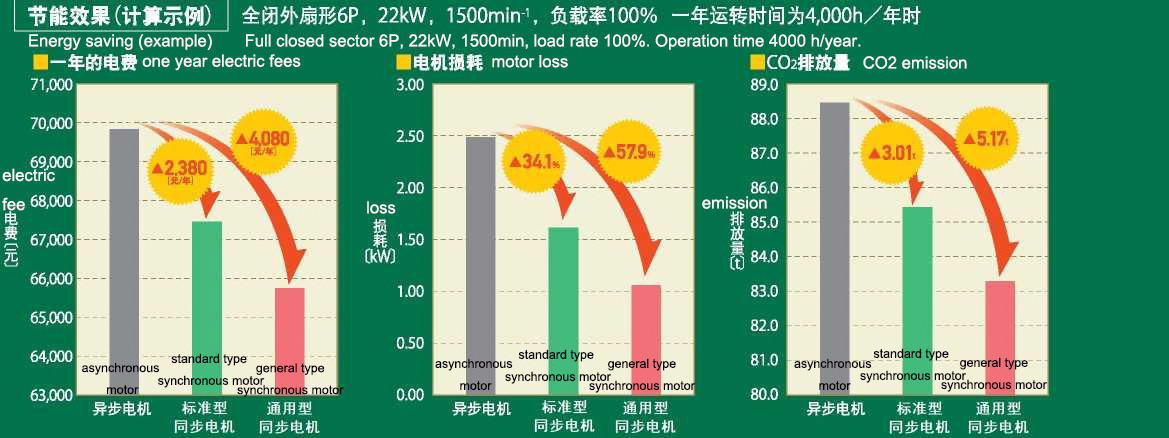

More energy saved by combined operation

By combining the synchronous motor with an independent frequency converter for energy-saving control, the power loss can be reduced and further high efficiency operation can be realized.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ENN

-

Model Number:

-

TYB

-

Frequency:

-

50-150HZ

-

Item:

-

Energy Saving 37.5kw 100 Hp Belt Conveyor Drive Electric Motor

-

Material:

-

Rare earth

-

Class of Insulation:

-

F

-

Cooling type:

-

IC411 or IC416

-

Protection grade:

-

IP54(IP23 Customizable)

-

Housing:

-

cast iron,aluminum case

-

Control method:

-

Variable frequency vector control

-

Number of Poles:

-

4,6,8,10,20,32,48,64,100

-

Mounting:

-

IMB3 IMB5 IMB35

-

Wire Type:

-

Junction box

Quick Details

-

AC Voltage:

-

380v,690v,1140v,6kv,10kv

-

Warranty:

-

12 months

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ENN

-

Model Number:

-

TYB

-

Frequency:

-

50-150HZ

-

Item:

-

Energy Saving 37.5kw 100 Hp Belt Conveyor Drive Electric Motor

-

Material:

-

Rare earth

-

Class of Insulation:

-

F

-

Cooling type:

-

IC411 or IC416

-

Protection grade:

-

IP54(IP23 Customizable)

-

Housing:

-

cast iron,aluminum case

-

Control method:

-

Variable frequency vector control

-

Number of Poles:

-

4,6,8,10,20,32,48,64,100

-

Mounting:

-

IMB3 IMB5 IMB35

-

Wire Type:

-

Junction box

Products Description

|

Energy efficiency standards

|

Comply with GB30253-1 grade

|

Work mode

|

S1

|

||

|

Installation dimensions

|

Comply with IEC standard

|

Control mode

|

Variable frequency vector control

|

||

|

Power range

|

7.5 〜160kW

|

Governing range

|

constant torque: 0〜3000r/min

|

||

|

Cooling way

|

IC411 (fan cooling)

|

|

weak magnet: 3000 〜3600r/min

|

||

|

Power range

|

7.5 〜250kW

|

Governing range

|

Constant torque: 0〜1500r/min

|

||

|

Cooling way

|

IC416 (independent axial flow fan)

|

|

Weak magnet: 1500 〜1800r/min

|

||

|

Insulation class

|

F

|

Optional parts

|

Encoder, spiral transformer, PTC, PT100

|

||

|

Protection grade

|

IP54 (IP23 customizabe)

|

Wiring type

|

Junction box (aviation plug can be customized as per requirement)

|

||

|

installation

|

IMB3 IMB5 IMB35

|

Service factor

|

Standard 1, 2 (customized as per requirement)

|

||

|

Required environment

|

below 1000m altitude

|

|

|

||

|

|

Temperature -15〜45°C

|

|

|

||

|

|

Relative humidity below 90%

|

|

|

||

|

Model

|

Power

(kW)

|

Rated volt (V)

|

Rated current

(A)

|

Frequency

(Hz)

|

No. of poles

|

Rated torque

(N • m )

|

Efficiency

(%)

|

Weight

(kg)

|

|

TYB-132M1-6

|

7.5

|

380

|

14.5

|

75

|

6

|

47.8

|

92.6

|

61

|

|

TYB-132M2-6

|

11

|

380

|

21

|

75

|

6

|

70

|

93.6

|

73

|

|

TYB-160M1-6

|

11

|

380

|

210

|

75

|

6

|

70

|

93.6

|

108

|

|

TYB-160M2-6

|

15

|

380

|

28.5

|

75

|

6

|

95.B

|

94

|

124

|

|

TYB-160L1-6

|

18.5

|

380

|

35.1

|

75

|

6

|

117.8

|

94.3

|

132

|

|

TYB-160L2-6

|

22

|

380

|

415

|

75

|

6

|

140

|

94.7

|

141

|

|

TYB-225S1-8

|

30

|

B80

|

56.4

|

100

|

8

|

191

|

95

|

261

|

|

TYB-225S2-8

|

37

|

380

|

69.4

|

100

|

8

|

235.6

|

953

|

274

|

|

TYB-225M1-8

|

45

|

380

|

84.1

|

100

|

8

|

286.5

|

95.6

|

284

|

|

TYB-225M2-8

|

55

|

380

|

102.6

|

100

|

8

|

350

|

95.8

|

297

|

|

TYB-225MX-8

|

75

|

380

|

141.7

|

100

|

8

|

477.5

|

96

|

336

|

|

TYB-280S-8

|

90

|

380

|

169.7

|

100

|

8

|

573

|

96.2

|

484

|

|

TYB-280M1-8

|

110

|

380

|

207

|

100

|

8

|

700

|

96.4

|

512

|

|

TYB-280M2-8

|

132

|

380

|

248.1

|

100

|

8

|

840

|

96.5

|

555

|

|

TYB-315S-8

|

160

|

380

|

300.8

|

100

|

8

|

1018.7

|

96.5

|

756

|

|

TYB-315M-8

|

200

|

380

|

375.6

|

100

|

8

|

1273.3

|

96.6

|

850

|

|

TYB-315L1-8

|

220

|

380

|

413.2

|

100

|

8

|

14007

|

96.6

|

910

|

|

TYB-315L2-8

|

250

|

380

|

469.1

|

100

|

8

|

15917

|

96.7

|

1055

|

|

Model

|

Power (kW)

|

Rated volt ( V)

|

Rated current (A)

|

Frequency (Hz)

|

No. of poles

|

Rated torque

(N • m )

|

Efficiency

(%)

|

Weight

(kg)

|

|

TYB-132M1-4

|

7.5

|

380

|

14.6

|

100

|

4

|

23.9

|

92.1

|

71

|

|

TYB-132M2-4

|

11

|

380

|

21.1

|

100

|

4

|

35

|

93

|

87

|

|

TYB-160M1-4

|

15

|

380

|

28.7

|

100

|

4

|

47.8

|

93.4

|

118

|

|

TYB-160M2-4

|

22

|

380

|

41.7

|

100

|

4

|

70

|

94.4

|

126

|

|

TYB-180M1-4

|

30

|

380

|

56.7

|

100

|

4

|

95.5

|

94.5

|

175

|

|

TYB-180M2-4

|

37

|

380

|

69.8

|

100

|

4

|

117.8

|

94.8

|

186

|

|

TYB-200L1-4

|

45

|

380

|

84.6

|

100

|

4

|

142.3

|

95.1

|

241

|

|

TYB-200L2-4

|

55

|

380

|

103.1

|

100

|

4

|

175

|

95.4

|

259

|

|

TYB-225M-4

|

75

|

380

|

141

|

100

|

4

|

238.8

|

95.6

|

388

|

|

TYB-225MX-4

|

90

|

380

|

168.7

|

100

|

4

|

286.5

|

95.8

|

421

|

|

TYB-280S1-8

|

110

|

380

|

205.7

|

200

|

8

|

350

|

96

|

486

|

|

TYB-280S2-8

|

132

|

380

|

246.9

|

200

|

8

|

420

|

96

|

534

|

|

TYB-280M-8

|

160

|

380

|

398.6

|

200

|

8

|

509

|

96.2

|

698

|

Details Images

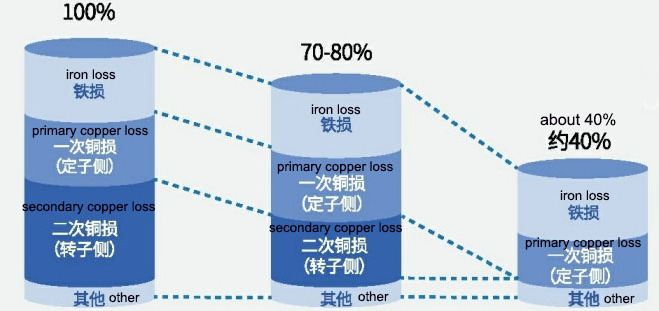

Loss Analysis

Permanent magnet synchronous motor

can

reduce iron loss and primary copper

loss

with no secondary copper loss.

High efficiency NdFeB permanent magnet is adopted, with no excitation loss. Special rotor structure design has greatly reduced the iron loss and stray loss. The motor efficiency is above IE4 standard, Compared with three-phase asynchronous motor, the efficiency is improved by 5-10% and power factor is increased by 10-15%.

High efficiency and high power factor can be maintained in the load range of 20% to 120%. The power factor can be 1, while three-phase asynchronous motor can only reach 0.86,it effectively reduces the cabling loss, and improves the utilization rate of the power grid. Energy saving is more significant under light load.

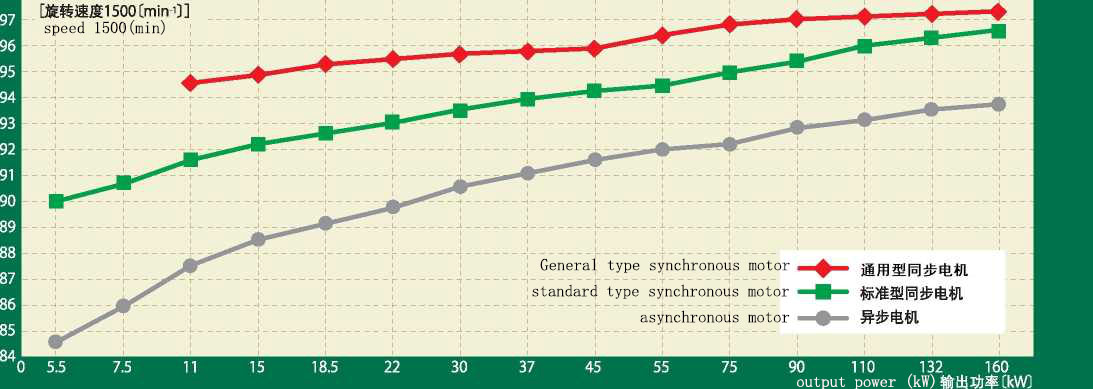

Standard type motor efficiency is equivalent to IE3 (high efficiency:>GB2 grade)

General type motor efficiency is above IE4 (ultra high efficiency:>GB1 grade)

General type motor efficiency is above IE4 (ultra high efficiency:>GB1 grade)

Comparison of Motor Efficiency

1) The efficiency of the above asynchronous motor is JISC 4210.

2) The efficiency of the above standard type synchronous motor is the value of IE3 specified in IEC 60034-30.

3) The above general type synchronous motor efficiency is the value of IE4 specified in IEC 60034-30.

2) The efficiency of the above standard type synchronous motor is the value of IE3 specified in IEC 60034-30.

3) The above general type synchronous motor efficiency is the value of IE4 specified in IEC 60034-30.

Main Features

1.Small and Light

Volume ratio: average 35% smaller, weight ratio: average 40% lighter

Motor seat No. is decreased by 1 ~ 3, compared with asynchronous motor.

It can realize mechanical miniaturization to save space.

It can realize mechanical miniaturization to save space.

2.

High Power Factor

Reduce the capacity of power receiving equipment.

There is no doubt of high efficiency. Compared with asynchronous motor, it may reduce the current volume of equipment due to high power factor.

3.

High Efficiency•Energy Saving

Motor efficiency is equal to IE4 (High efficiency: above GB1 level)

Factory Show

FAQ

1.What is the heat resistance rating of permanent magnets? What will cause demagnetization?

The permanent magnets commonly used in our company are neodymium-boron-iron materials, and their maximum operating temperature is different depending on the grades used. For example, N38EH, the maximum working temperature of its material can reach 200℃, but we redesign it according to 180℃ as the limit.

To put it simply, our products are designed with sufficient margin, and there will be no demagnetization due to high temperature during use. As long as there is no high current impact, the permanent magnets of the motor will not demagnetize, and the use of inverters can avoid the occurrence of high currents.

2. What is the usual noise of the motor running?

Motor noise varies greatly depending on the specifications of the motor. Permanent magnet motors running below 200 rpm usually have a noise below 80dab. The noise of permanent magnet motors with operating speeds above 750 rpm is generally around 85dab.

Meet the relevant regulations of GB100693.-2008 "Rotating Electric Machine Noise Measurement Method and Limits".

3.

What are the contents of operation and maintenance?

The motor basically has no operating costs and only requires routine maintenance. If the environment is poor, the motor with the external fan and the attachments of the external fan need to be cleaned regularly to avoid additional power loss.

Contact Us

|

Qingdao Enneng Motor Co.,ltd

|

|

|

|

|

||||

|

Tel:

|

+86 532 66000559

|

Email:

|

sales@enpmsm.com

|

|

||||

|

Mobile:

|

+86 18562780228

|

Website:

|

www.enpmsm.com

|

|

||||

|

Address:

|

D2-3 Building, Ti Park, No.2 Xiuyuan Road,High-Tech Zone,

Qingdao, Shandong, China

|

|

|

|

||||

Hot Searches