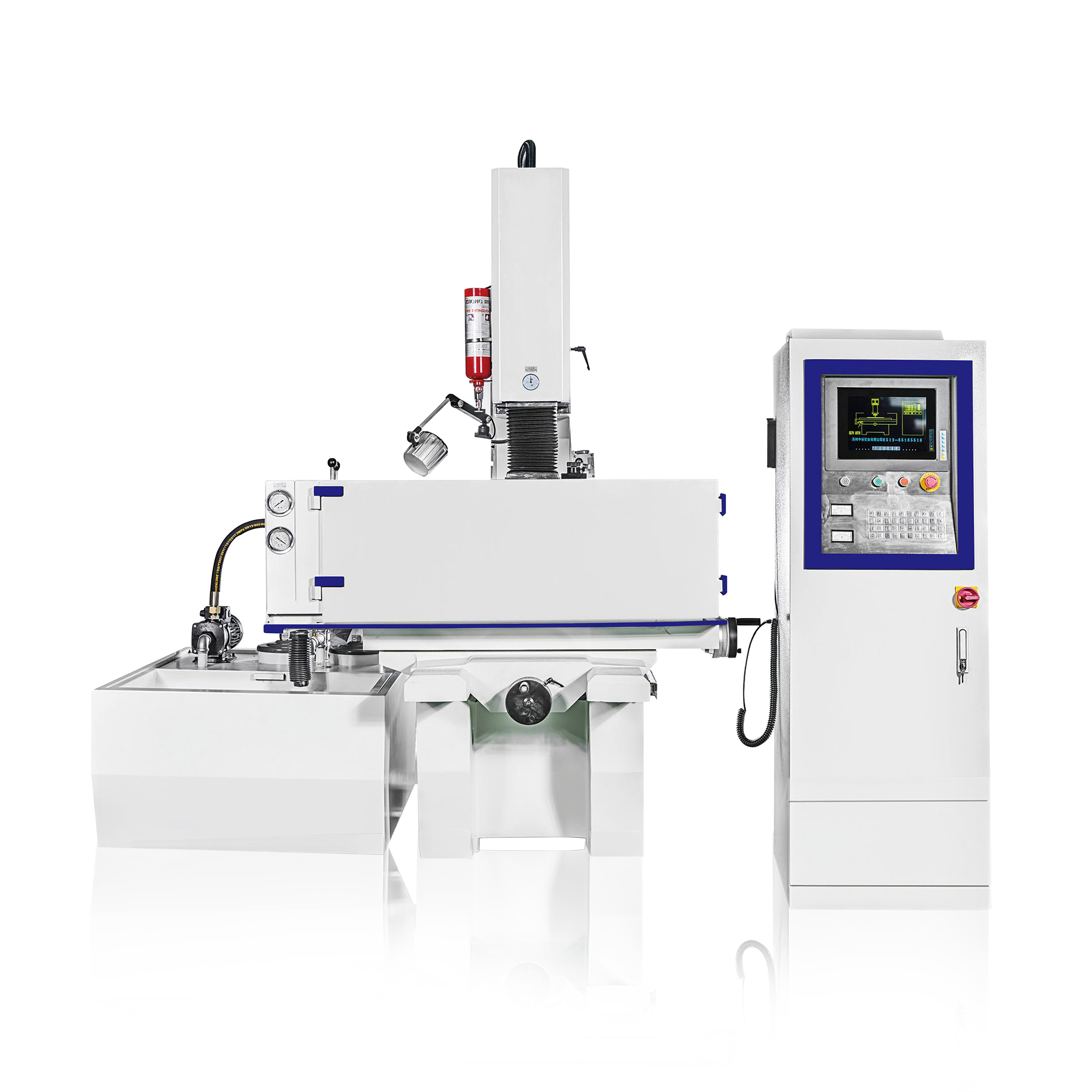

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1000*750*2000

-

Weight (KG):

-

950

-

Power (kW):

-

3

-

Model:

-

ZGD703CNC

-

Work Table Dimensions:

-

550*360

-

Extemal Dimensions:

-

1000*750*2000

-

Travel(X*Y*Z):

-

350*250*(380+300)

-

Max Load of Work Table:

-

350kg

-

Diameter of the Electrode:

-

0.15-3

-

Max Process Depth:

-

400

-

Max Pressure of the Working Water:

-

140kg/cm2

-

Flume Dimension:

-

800*450

-

Max Diameter to Depth Ration:

-

≥300

Quick Details

-

Place of Origin:

-

CHINA JIANGSU

-

Brand Name:

-

SMAC

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

1000*750*2000

-

Weight (KG):

-

950

-

Power (kW):

-

3

-

Model:

-

ZGD703CNC

-

Work Table Dimensions:

-

550*360

-

Extemal Dimensions:

-

1000*750*2000

-

Travel(X*Y*Z):

-

350*250*(380+300)

-

Max Load of Work Table:

-

350kg

-

Diameter of the Electrode:

-

0.15-3

-

Max Process Depth:

-

400

-

Max Pressure of the Working Water:

-

140kg/cm2

-

Flume Dimension:

-

800*450

-

Max Diameter to Depth Ration:

-

≥300

Recommend Products

Products Description

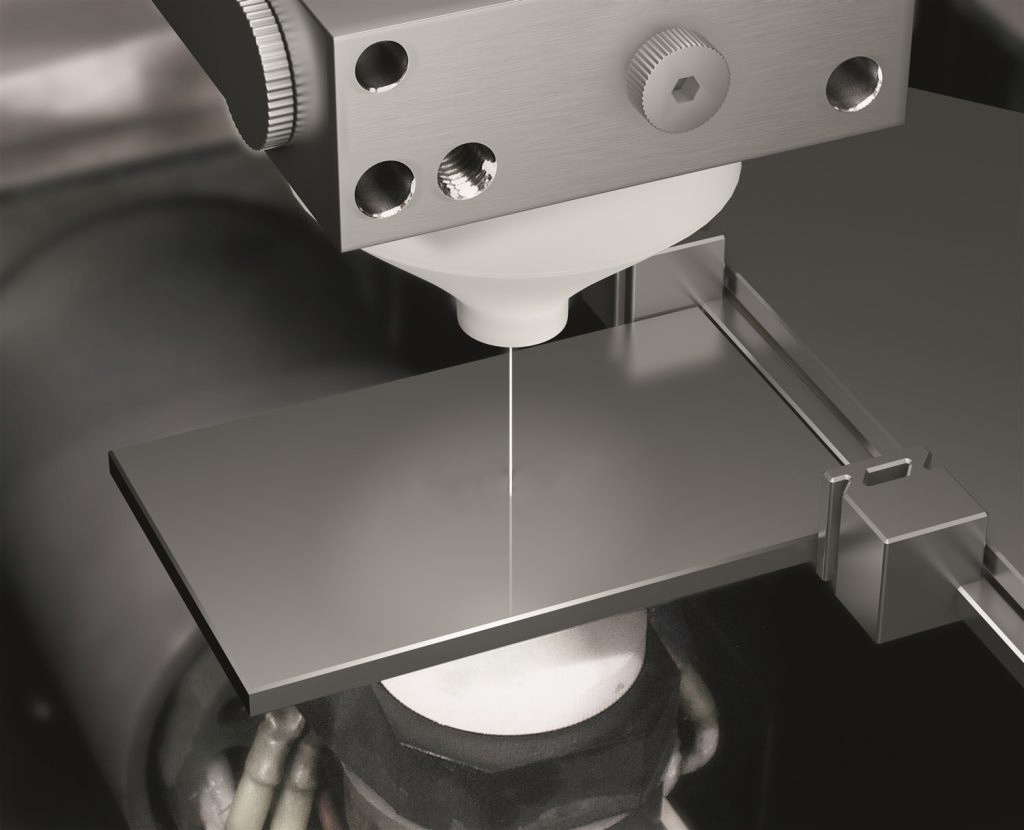

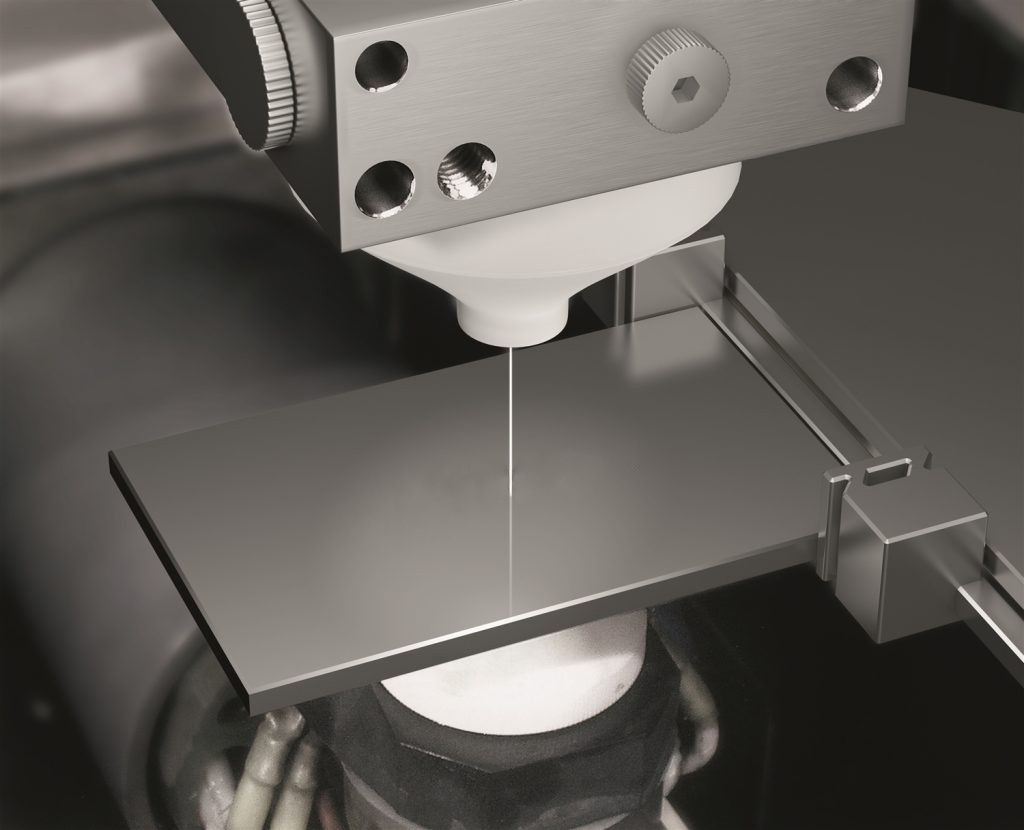

EDM is a machining process, which mainly uses the discharge electrode (EDM electrode) with specific geometry to burn the geometry of the electrode on metal (conductive) parts. EDM process is often used in the production of blanking die and mold.

Characteristic

Specifcation

|

Model

|

ZGD703CNC

|

|

Work Table Dimensions

|

550*360

|

|

Extemal Dimensions

|

1000*750*2000

|

|

Travel(X*Y*Z)

|

350*250*(380+300)

|

|

Max Load of Work Table

|

350kg

|

|

Diameter of the Electrode

|

0.15-3

|

|

Max Process Depth

|

400

|

|

Max Pressure of the Working Water

|

140kg/cm2

|

|

Flume Dimension

|

800*450

|

|

Max Diameter to Depth Ration

|

≥300

|

|

Machine Weight

|

950kg

|

Hot Searches