- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

3000*800*1400mm

-

Weight:

-

3.5T

-

Warranty:

-

12 Months

-

Feeding width:

-

according to sample panel size

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model Number:

-

35C/ 55U/ 65C/ 65U/ 70C

-

Frame material:

-

350 H-high grade steel

-

Size of container:

-

20GP

-

Control System:

-

PLC with touch screen

-

Roll material:

-

45# high grade steel

-

Cutting blade material:

-

Cr 12 high grade steel

-

Feature:

-

Sheet Metal Tile Forming Machine

-

Work Pressure:

-

195 mpa---350 mpa

-

Shaft material::

-

45# high grade steel

-

Certification:

-

CE/ISO9001

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

8-15m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

3000*800*1400mm

-

Weight:

-

3.5T

-

Warranty:

-

12 Months

-

Feeding width:

-

according to sample panel size

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model Number:

-

35C/ 55U/ 65C/ 65U/ 70C

-

Frame material:

-

350 H-high grade steel

-

Size of container:

-

20GP

-

Control System:

-

PLC with touch screen

-

Roll material:

-

45# high grade steel

-

Cutting blade material:

-

Cr 12 high grade steel

-

Feature:

-

Sheet Metal Tile Forming Machine

-

Work Pressure:

-

195 mpa---350 mpa

-

Shaft material::

-

45# high grade steel

-

Certification:

-

CE/ISO9001

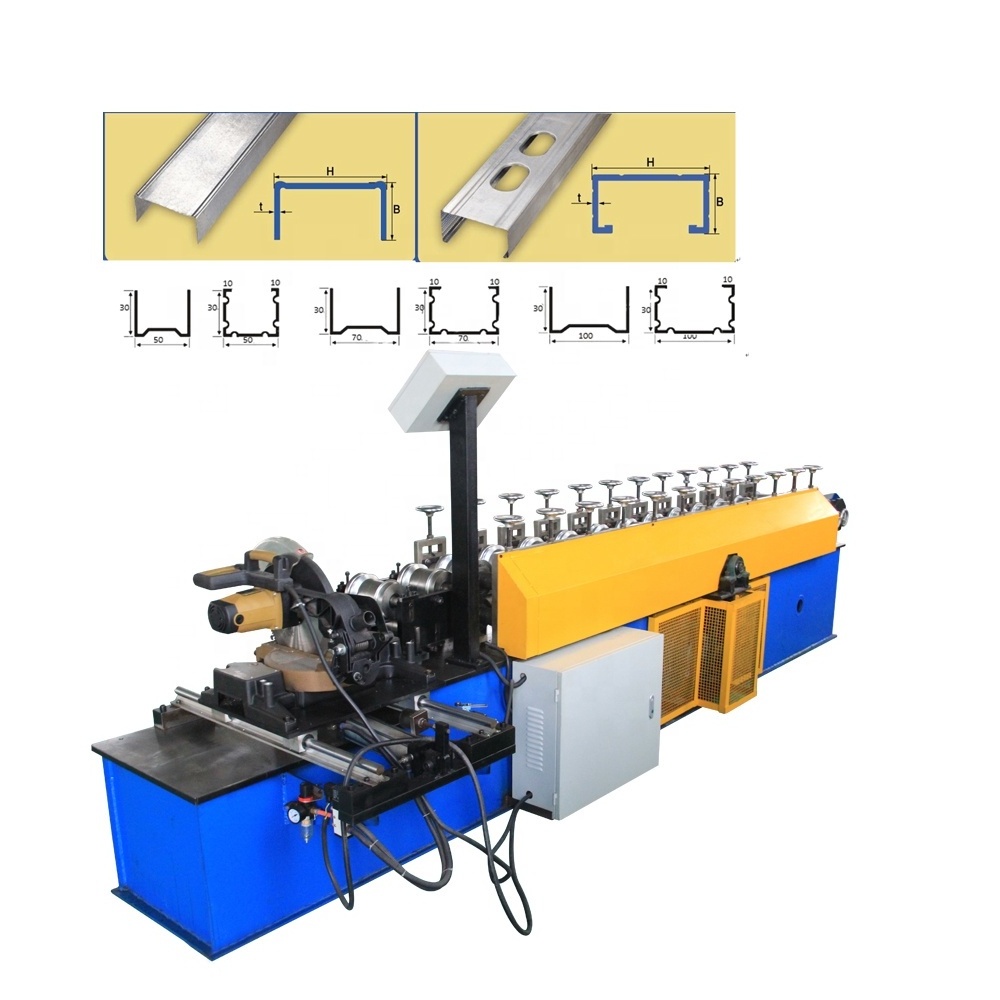

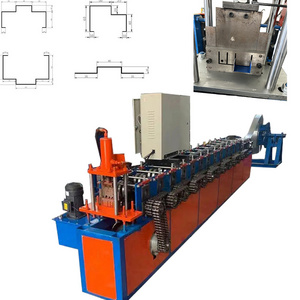

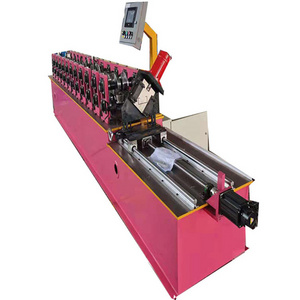

Steel C Channel Roll Forming Machine

C Z U L W Shape Profile Section Light Steel Keel Machine

What is the technical parameters of the machine?

|

Technical parameters: |

||

| 1 |

Hydraulic motor power |

3 kw ,4kw |

| 2 |

Hydraulic Pressure |

10-12MPa |

| 3 |

Voltage |

380V /3phase/ 50 HZ (or as your requirement) |

| 4 |

C utting drive |

Decelerating motor + Chain drive gear all by high-frequency |

| 5 |

Control System |

Panasonic /Siemens / Schneider / Delta PLC |

| 6 |

Length measurement |

Encoder |

| 7 |

Main Frame |

300mm/350mm H-Beam or 350mm |

| 8 |

Backboard Thickness |

17 mm /20mm |

| 9 |

Chain Size |

1inch/2inch |

| 10 | Feeding Material | B etter as your drawing or from our designer |

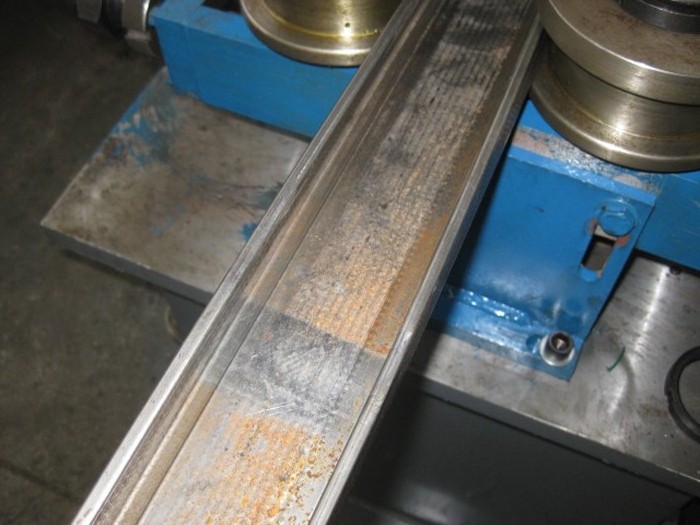

| 11 | Feeding Thickness | 0.18mm-0.8mm |

| 12 | Effective width | B etter as your drawing or from our designer |

| 13 | Productivity | 12-20 /min |

| 14 | Roll Station | 12rows (according to different design) |

| 15 | Roller Diameter | 40 mm(depend on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

| 18 | Total Weight | 2t-12t |

| 19 |

Package of machine |

Waterproofing membrane, standard export packing |

| 20 |

R oll fromiomg machine of the Components |

Manual de coiler-------------------1 set (5t) Guiding Platform------------------1 set Main Machine of Roll Forming------1 set Hydraulic Station------------------1 set Supporter Table-------------------1 set |

| 21 | machine technical parameters can be changed, according to customer's need. | |

What is the details of the machine?

The ordinary profile drawing of the steel stamping studs:

The components of the steel stud roll forming line:

PLC control system withTouch screen

Manual de coiler:

Container packing of the line suitable for overseas shipping.Free packaging for you: Standard export packing:20feet or 40 feet GP container ; main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, control box will be packed with carton box.

Mob/Whatsapp:+8618920411229

1.

Installation and training:

a.If buyers visit our factory and check the machine, we will teach you how to install

and use the machine, and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

c.If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

2. After Service

a.One year guarantee for whole machine.

b.24 hours technical support by email or calling

c.If there is any problem found of the machine, we will repair it for free in one year.