- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Terminals lugs

-

Material:

-

copper, aluminum

-

Process:

-

Welding,slitting,CNC,Electroplating

-

Configuration:

-

Customizable

-

Usage:

-

Wire Connecting

-

Application:

-

Electrical equipment ,power distribution box

-

Feature:

-

Anti-electrochemical corrosion

-

OEM/ODM:

-

Accepted

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

sanxie

-

Model Number:

-

SX

-

Product name:

-

Terminals lugs

-

Material:

-

copper, aluminum

-

Process:

-

Welding,slitting,CNC,Electroplating

-

Configuration:

-

Customizable

-

Usage:

-

Wire Connecting

-

Application:

-

Electrical equipment ,power distribution box

-

Feature:

-

Anti-electrochemical corrosion

-

OEM/ODM:

-

Accepted

Product Paramenters

|

Material

|

Copper T2, Aluminum 1060

|

|

|

|

Specification(thickness * width)

|

0.1mm-15mm*30mm-1000mm

|

|

|

|

Copper and Aluminum weight ratio

|

Cu:AL

|

32%-40%: 60%-68%

|

|

|

Copper and Aluminum volume ratio

|

Cu:AL

|

15-20: 80-85

|

|

|

Resistivity(Ωmm2/m)

|

≦0.024

|

|

|

|

Elongation (%)

|

15%~30%

|

|

|

|

Tensile strength(MPa)

|

150-170Mpa

|

|

|

|

peel strength(N/mm)

|

more than 12

|

|

|

|

Surface hardness(HV 0.3)

|

76/37

|

|

|

|

composite rate (%)

|

100%

|

|

|

Specification

|

Specification a*b(mm)

|

3*30

|

3*40

|

3*50

|

|

|

|

|

|

|

Weight/meter(kg)

|

0.31

|

0.42

|

0.53

|

|

|

|

|

|

|

Specification a*b(mm)

|

4*40

|

4*50

|

4*60

|

4*80

|

|

|

|

|

|

Weight/meter(kg)

|

0.56

|

0.7

|

0.84

|

1.12

|

|

|

|

|

|

Specification a*b(mm)

|

5*40

|

5*50

|

5*60

|

5*80

|

|

|

|

|

|

Weight/meter(kg)

|

0.7

|

0.875

|

1.05

|

1.4

|

|

|

|

|

|

Specification a*b(mm)

|

6.4

|

6*50

|

6*60

|

6*80

|

6*100

|

|

|

|

|

Weight/meter(kg)

|

0.84

|

1.05

|

1.26

|

1.68

|

2.1

|

|

|

|

|

Specification a*b(mm)

|

8*50

|

8*60

|

8*80

|

8*100

|

8*120

|

8*200

|

|

|

|

Weight/meter(kg)

|

1.4

|

1.68

|

2.24

|

2.8

|

3.36

|

5.6

|

|

|

|

Specification a*b(mm)

|

10*60

|

10*80

|

10*100

|

10*120

|

10*150

|

10*200

|

10*250

|

10*300

|

|

Weight/meter(kg)

|

2.1

|

2.8

|

3.5

|

4.2

|

5.25

|

7

|

8.75

|

10.5

|

Products Description

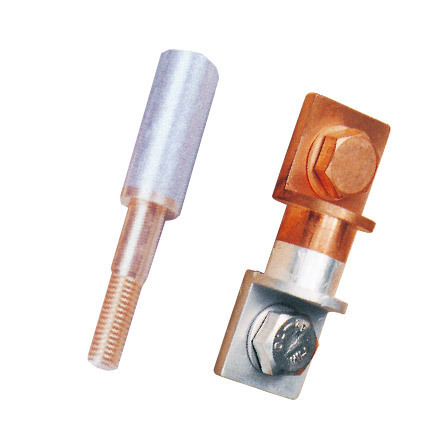

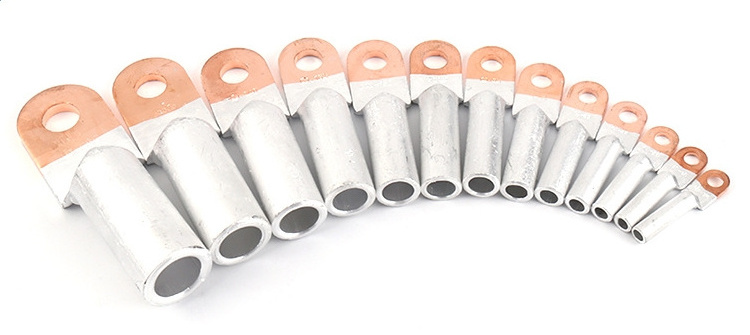

Bimetal al-cu terminal lug

They are used to connect different cables at one point and maintain the electrical flow in the circuit.

Specifically,t

hey are used to connect aluminum cables to copper bus bars to prevent galvanic action due to dissimilar contact. These lugs are also used to connect two cables in a single joint to reduce contact resistance and corrosion. These lugs can be used for grounding wires occasionally.

1.Process:

Welding

process allows copper and aluminum to be permanently and firmly bonded in an oxygen free environment, ensuring 100% metallurgical bonding.

2Application scenarios:

They are suitable for transition connection of the circular aluminum wires, hcmicycle sector aluminum wired, power supply cables in the distribution equipment and copper terminals of electrical equipment.

They are currently used in heat engines and circuit breakers and so on ,that prevent excess current flow ,and mainly used for transmitting current between the interconnected conductors.

High voltage transformer

Distribution box

High-speed rail industry

New energy electric car

Shipping industry

Transformer

3.Other advantages:

(1)H

igh welding strength,a

nti-corrosion, wear resistance, good electrical and thermal conductivity, and low cost.

(2)Good mechanical properties: Excellent tensile strength, flexibility and ductility.

4.OEM/ODM accepted:

We can also customize the design and development of these terminal lug according to the specific requirements of customers.

5.

Various customization:

In addition to copper aluminum composite terminal lug, there are also many products made of bimetallic materials. We accept various customizations.

|

customize

|

material

|

Copper:Purple Copper T2 (C1100) /Brass H62 / H65

Aluminum: 1060 / 1070/ 8010 / 1100 / 3003 /5052

Others:Steels/Nickel/Zinc......

|

|

|

shape

|

Sheet / Plates / Strip / terminal lug / boss / foil / Washers / PG clamp / earthing block / Customized Design

|

|

|

Thickness

|

0.07mm/ 0.1mm/14.5mm/according to your needs.

|

|

|

Width

|

according to your needs.

|

|

|

Length

|

according to your needs.

|

|

|

Ratio

|

according to your needs.

|

|

|

Configuration

|

Whether it is Inlay clad, Overlay clad, or welded clad, the specific configuration can be customized

|

Hot Searches